Novel plasma gasifier and operation process thereof

A technology of plasma and gasification furnace, applied in the field of plasma gasification furnace and its operation process, can solve problems such as substandard cement quality, production safety accidents, and insufficient processing temperature, so as to avoid shutdown conditions and reduce secondary The generation of secondary waste and the effect of improving the burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0022] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

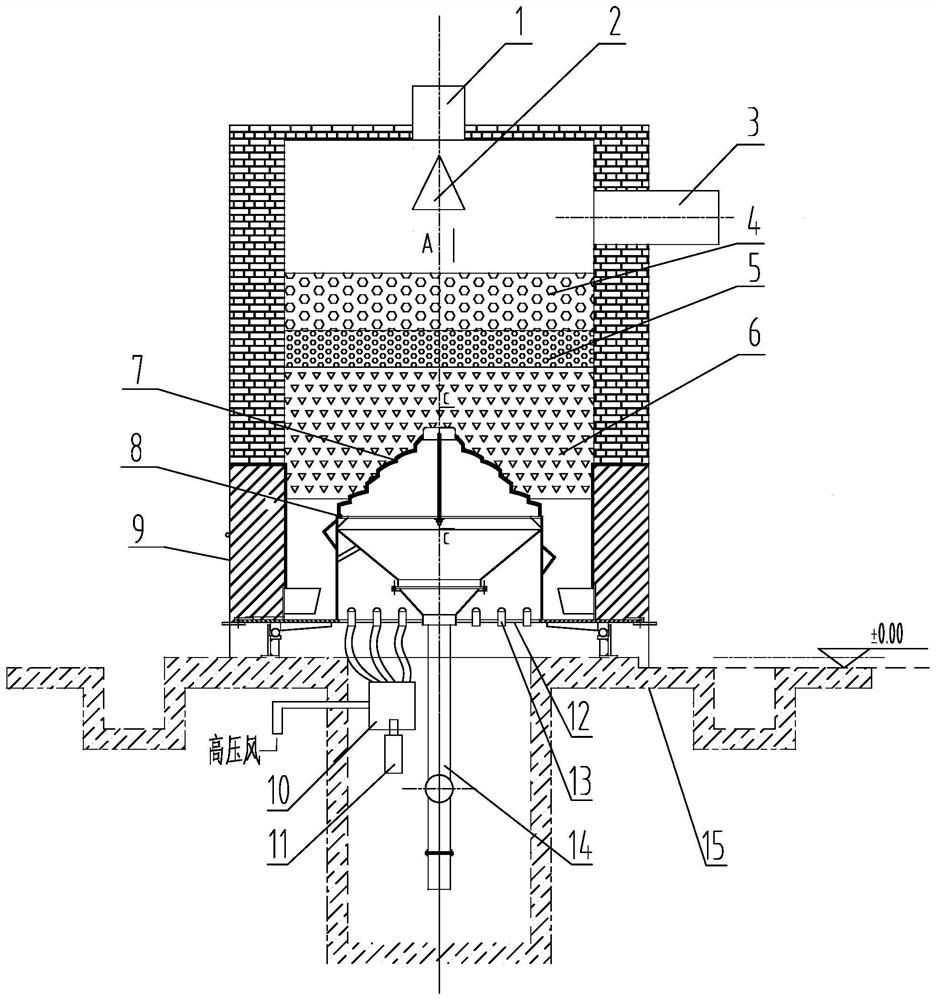

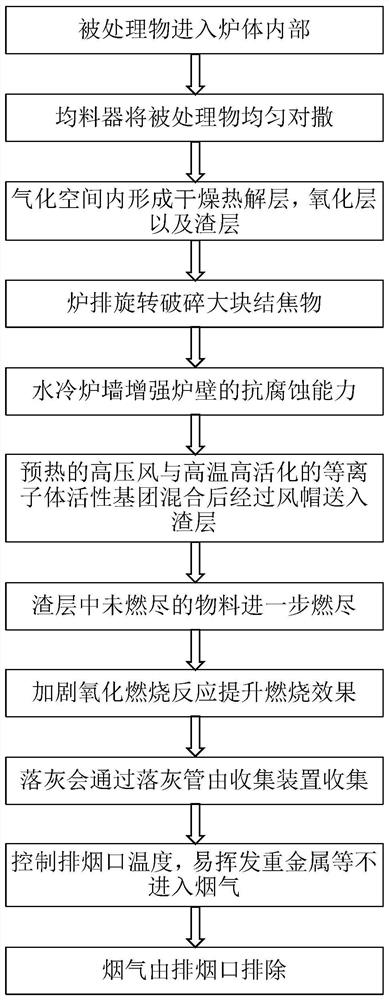

[0023] Such as figure 1 As shown, a novel plasma gasification furnace according to a preferred embodiment of the present invention includes: a feed inlet 1 arranged on the top of the furnace body, and the broken and compatible hazardous waste enters the interior of the furnace body through the feed inlet 1; The homogenizer 2 arranged under the feed port 1; the fire grate 7 rotatably arranged under the homogenizer 2, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com