preparation of anti-charge-accumulation insulating oil from nano TiO2 modified sunflower seed oil

A technology of sunflower oil and charge accumulation, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems such as the inability to ensure the safe operation of insulating oil paper, and achieve the goal of improving the anti-charge accumulation performance, improving compatibility, and solving agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

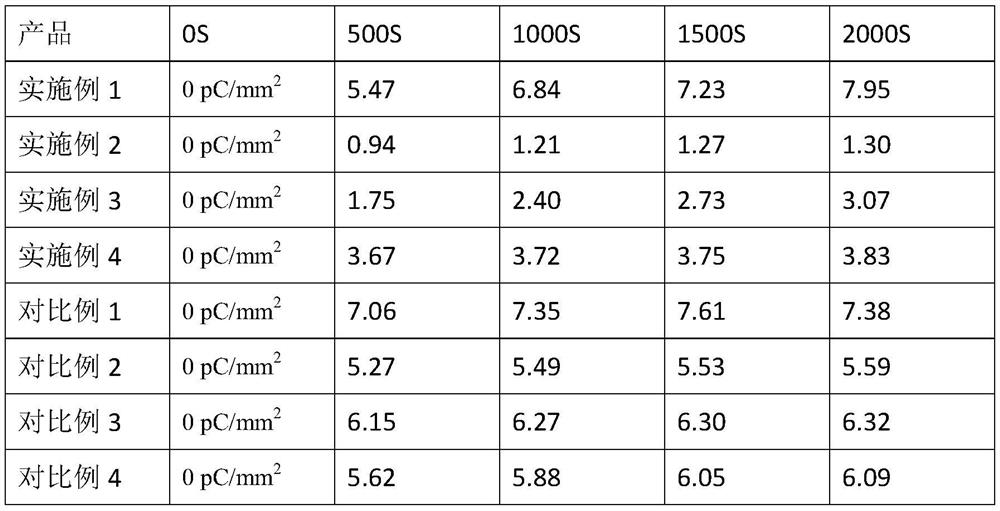

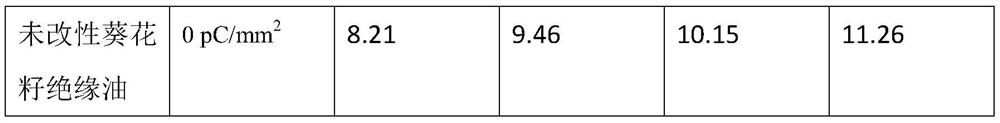

Examples

Embodiment 1

[0024] A kind of nano-TiO 2 Modified sunflower oil prepares anti-charge accumulation insulating oil, comprising the following steps:

[0025] (1) Preparation of modified nano-TiO 2 : Weigh 5g TiO 2 Put the nanoparticles into the grinder, grind for 3 hours at a speed of 300r / min, and then put the nano-TiO 2 Add in 200ml dehydrated alcohol and mix, add the modifier that is oleic acid, acrylic acid rosin polyoxyethylene sucrose ester and the polyethylene glycol composition of 3:1:1 mass ratio to carry out surface modification to mixed solution again, so The amount of modifier added is TiO 2 8%, washed with ethanol, fully dried at a pressure of 50Pa and a temperature of 60°C to obtain modified nano-TiO 2 .

[0026] (2)TiO 2 Modified sunflower oil: vacuum-dry 500g of sunflower seed insulating oil at room temperature, heat to 45°C, stir for 30min at a speed of 100r / min, and then add the above-mentioned modified nano-TiO to the sunflower seed insulating oil 2 , under the power...

Embodiment 2

[0028] A kind of nano-TiO 2 Modified sunflower oil prepares anti-charge accumulation insulating oil, comprising the following steps:

[0029] (1) Preparation of modified nano-TiO 2 : Weigh 10g TiO 2 Put the nanoparticles into the grinding machine, grind for 2 hours at a speed of 500r / min, and then put the nano-TiO 2 Add in 200ml dehydrated alcohol and mix, add the modifier that is 4:2:1 oleic acid, acrylic acid rosin polyoxyethylene sucrose ester and polyethylene glycol composition to carry out surface modification in the mixed solution again, so The amount of modifier added is TiO 2 7%, washed with ethanol, fully dried at a pressure of 50Pa and a temperature of 60°C to obtain modified nano-TiO 2 .

[0030] (2)TiO 2 Modified sunflower oil: Vacuum dry 500g of sunflower seed insulating oil at room temperature, heat to 50°C, stir for 60min at a speed of 50r / min, and then add the above-mentioned modified nano-TiO to the sunflower seed insulating oil 2 , under the power of 1...

Embodiment 3

[0032] A kind of nano-TiO 2 Modified sunflower oil prepares anti-charge accumulation insulating oil, comprising the following steps:

[0033] (1) Preparation of modified nano-TiO 2 : Weigh 15g TiO 2 Nanoparticles were put into a grinder, and ground for 2.5h at a speed of 400r / min, and then the nano-TiO 2 Add in 200ml dehydrated alcohol and mix, then add the modifier that the mass ratio is 3:2:1 oleic acid, acrylic acid rosin polyoxyethylene sucrose ester and polyethylene glycol composition to the mixed solution to carry out surface modification, so The amount of modifier added is TiO 2 6%, washed with ethanol, and fully dried at 60Pa pressure and 70°C temperature to obtain modified nano-TiO 2 .

[0034] (2)TiO 2 Modified sunflower oil: Vacuum-dry 500g of sunflower seed insulating oil at room temperature, heat to 55°C, stir for 30min at a speed of 150r / min, and then add the above-mentioned modified nano-TiO to the sunflower seed insulating oil 2 , under the power of 1200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com