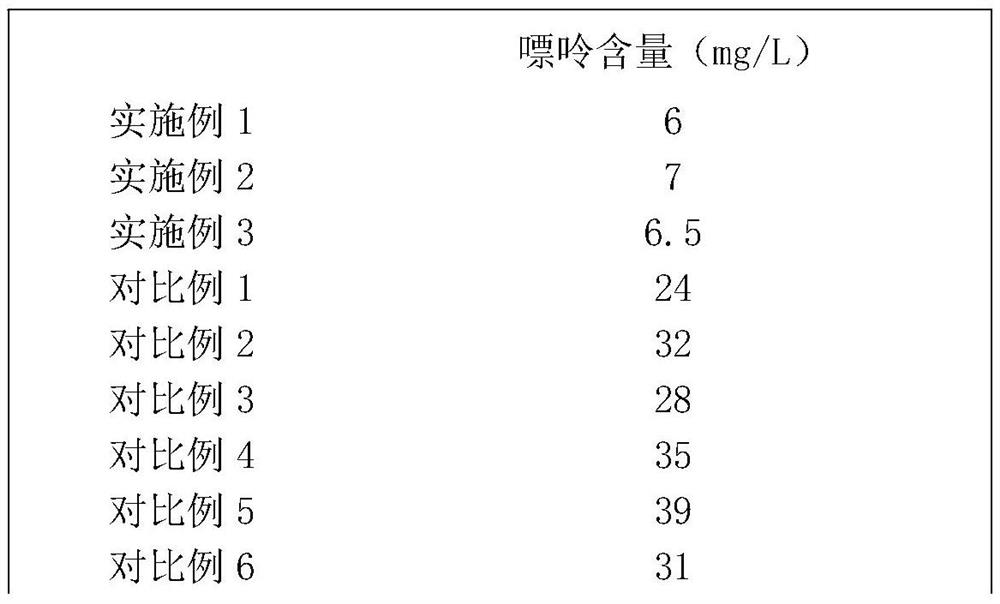

Production method for reducing purine content in beer

A production method and a purine medium technology are applied in the production field of reducing the purine content in beer, can solve the problem of reducing the purine content of beer and beer, and achieve the effects of increasing adsorption capacity, improving yeast activity and reducing purine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

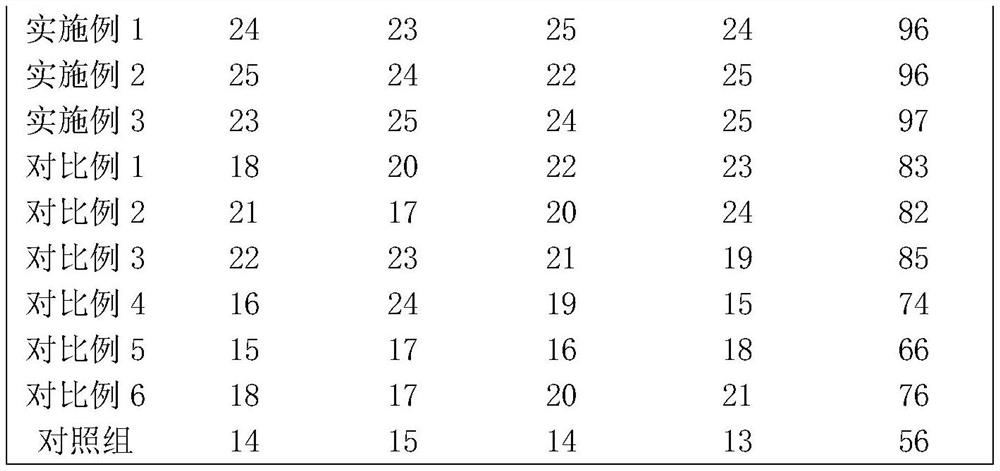

Examples

Embodiment 1

[0032] (1) remove the malt seed coat and germ, pulverize to obtain malt powder, and set aside;

[0033] (2) Add 24kg of malt powder, 9kg of cornstarch, 10g of protease with a protease activity of 50,000 / mL and 165L of water into the mash tun, adjust the pH to 5.5, add 2.5% lactic acid of malt quality and then brew at a temperature of 38°C After 10 minutes of heat preservation, the temperature was raised to 50°C, and the heat preservation was continued for 1 hour;

[0034] (3) Add 35kg of rice flour, 145L of water and 0.1% high temperature-resistant a-amylase of rice flour quality into the gelatinization pot, adjust the pH to 5.8, keep the temperature at 50°C for 20min, then heat up to 97°C and keep it warm 20min, obtain mash;

[0035] (4) Pour all the mash into the mash pot and control the temperature at 62°C, keep it warm for 30 minutes, then raise the temperature to 68°C and keep it warm for 20 minutes, then raise the temperature to 76°C to inactivate the enzyme to obtain w...

Embodiment 2

[0039] (1) remove the malt seed coat and germ, pulverize to obtain malt powder, and set aside;

[0040] (2) Add 26kg of malt powder, 8kg of cornstarch, 10g of protease with a protease activity of 50,000 / mL and 170L of water into the mash pot, adjust the pH to 5.6, add 2% lactic acid of the malt mass, and store at 36°C After 10 minutes of heat preservation, the temperature was raised to 52°C, and the heat preservation was continued for 1 hour;

[0041] (3) Add 33kg of rice flour, 140L of water and 0.1% high temperature-resistant a-amylase of rice flour quality into the gelatinization pot, adjust the pH to 5.6, keep the temperature at 50°C for 20min, then heat up to 95°C and keep it warm 20min, obtain mash;

[0042] (4) Pour all the mash into the mash pot and control the temperature at 64°C, heat it for 30 minutes, then raise the temperature to 70°C and keep it for 20 minutes, then heat it up to 76°C to inactivate the enzyme to obtain wort;

[0043] (5) Add 1.5% nitric acid mo...

Embodiment 3

[0046] (1) remove the malt seed coat and germ, pulverize to obtain malt powder, and set aside;

[0047](2) Add 22kg of malt powder, 10kg of cornstarch, 10g of protease with a protease activity of 50,000 / mL and 160L of water into the mash tun, adjust the pH to 5.4, add 3% lactic acid of the malt mass, and cook at 40°C After 10 minutes of heat preservation, the temperature was raised to 48°C, and the heat preservation was continued for 1 hour;

[0048] (3) Add 37kg of rice flour, 150L of water and 0.1% high temperature-resistant a-amylase of rice flour quality into the gelatinization pot, adjust the pH to 6.0, keep the temperature at 52°C for 20min, then heat up to 100°C and keep it warm 20min, obtain mash;

[0049] (4) Pour all the mash into the mash pot and control the temperature at 60°C, heat it up to 66°C for 20 minutes after keeping it warm for 30 minutes, then heat it up to 76°C to kill enzymes, and obtain wort;

[0050] (5) Add 1.5% nitric acid modified activated carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com