Deep-sea fish processing method for reducing purine and mercury contents

A processing method and technology for deep-sea fish, applied in the field of food processing, can solve the problem of high content of mercury and purine, and achieve the effects of reducing the content of purine and mercury, ensuring food safety and effective removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

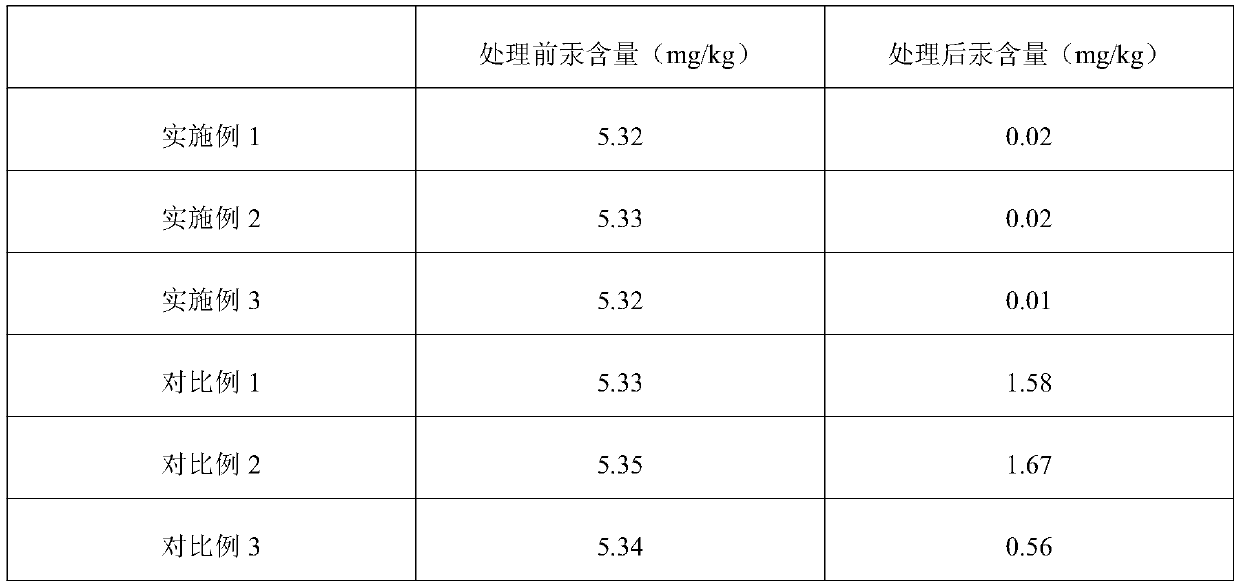

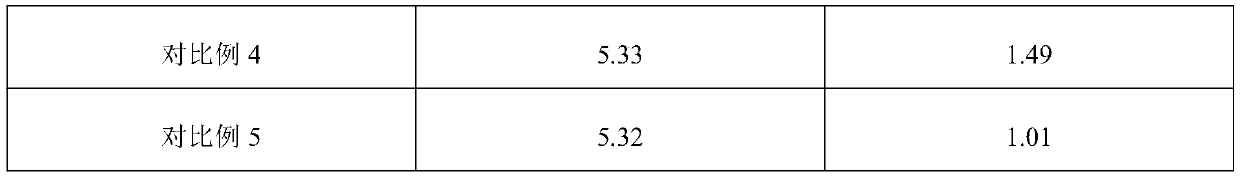

Examples

Embodiment 1

[0039] A deep-sea fish processing method for reducing purine and mercury content, in parts by weight, the specific steps are as follows:

[0040] (1) First mash 1 part of ginkgo fruit, 1.5 parts of celery and 0.5 part of okra into a slurry, squeeze out the liquid, filter to obtain the filter residue and filtrate, the filter residue enters step (2), and add 0.002 parts of bromelain and 0.001 part of Chinese okra to the filtrate Protease, enzymatic hydrolysis, enzyme inactivation, centrifugation to get the first supernatant, add 0.008 part of ferrous chloride to the first supernatant, chelate, centrifuge, get the second supernatant;

[0041] (2) Then the filter residue is vacuum freeze-dried for the first time, then poured into 6 parts of deionized water, ultrasonically dispersed for 20 minutes, vacuum freeze-dried for the second time, ultrafinely pulverized to obtain ultrafine powder, and then polyethylene glycol 400 is used to Hydrophilic modification of superfine powder to make...

Embodiment 2

[0059] A deep-sea fish processing method for reducing purine and mercury content, in parts by weight, the specific steps are as follows:

[0060] (1) First mash 1 part of ginkgo fruit, 2 parts of celery and 0.3 part of okra into a slurry, squeeze out the liquid, filter to obtain the filter residue and filtrate, the filter residue enters step (2), add 0.004 part of bromelain and 0.0008 part of Chinese okra to the filtrate Protease, enzymolysis, enzyme inactivation, centrifugation to take the first supernatant, add 0.01 part of ferrous chloride to the first supernatant, chelate, centrifuge, take the second supernatant;

[0061] (2) Then carry out the first vacuum freeze-drying of the filter residue, then pour it into 4 parts of deionized water, disperse it by ultrasonic wave for 30 minutes, vacuum freeze-dry it for the second time, and ultrafinely pulverize it to obtain superfine powder, then use polyethylene glycol 400 to Hydrophilic modification of superfine powder to make hyd...

Embodiment 3

[0079] A deep-sea fish processing method for reducing purine and mercury content, in parts by weight, the specific steps are as follows:

[0080] (1) First mash 1 part of ginkgo fruit, 1.8 parts of celery and 0.4 part of okra into a slurry, squeeze out the liquid, filter to obtain the filter residue and filtrate, the filter residue enters step (2), add 0.003 part of bromelain and 0.0009 part of Chinese okra to the filtrate Protease, enzymolysis, enzyme inactivation, centrifugation to get the first supernatant, add 0.009 part of ferrous chloride to the first supernatant, chelate, centrifuge, get the second supernatant;

[0081] (2) Then the filter residue is vacuum freeze-dried for the first time, then poured into 5 parts of deionized water, ultrasonically dispersed for 25 minutes, vacuum freeze-dried for the second time, ultrafinely pulverized to obtain ultrafine powder, and then polyethylene glycol 400 is used to Hydrophilic modification of superfine powder to make hydrophili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com