A preparation process of antibacterial and water-resistant composite leather for automotive trim

A preparation process and a technology for automotive trims, applied in the field of auto parts, can solve the problems of restricting the development and popularization of leather products, reducing the service life, bacterial growth, etc., and achieve the effects of strong penetration, long service life and stable products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

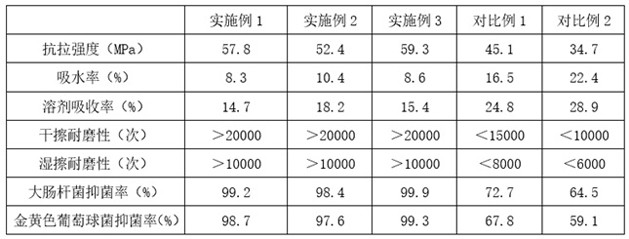

Examples

Embodiment 1

[0042] A preparation process for an antibacterial and water-resistant composite leather for automotive trim, comprising the following steps:

[0043] Step 1, wash the skin embryo with ethanol and pure water alternately at least twice to remove the stains on the surface, then place it in a drum with 0.3% formic acid solution and rotate it for 0.4h, after draining, add the retanning agent solution Rotate in the drum for 0.4h, after draining water again, add neutralizing solution and rotate in the drum for 0.5h, add neutralizing liquid after draining for the third time and rotate in the drum for 0.5h, after draining for the fourth time, put the skin embryo Put it under the condition of 75~90℃ and dry it until the water content is 30% to obtain the pre-treated product of skin embryo; wherein, the retanning agent solution is obtained by mixing acrylic resin retanning agent and deionized water according to the mass ratio of 2:100 , the neutralizing solution is obtained by mixing the...

Embodiment 2

[0054] A preparation process for an antibacterial and water-resistant composite leather for automotive trim, comprising the following steps:

[0055] Step 1, wash the skin embryo with ethanol and pure water alternately at least twice to remove surface stains, and then place it in a drum with 0.1% formic acid solution and rotate it for 0.5h, after draining, add retanning agent solution Rotate in the drum for 0.5h, after draining water again, add neutralizing solution and rotate in the drum for 0.8h, add neutralizing liquid and rotate in the drum for 0.8h after draining for the third time, after draining for the fourth time, put the skin embryo Put it under the condition of 75~90℃ and dry it until the water content is 25% to obtain the pre-treated skin embryo; wherein, the retanning agent solution is obtained by mixing amino resin retanning agent and deionized water according to the mass ratio of 1:100 , the neutralizing solution is obtained by mixing the neutralizing retanning ...

Embodiment 3

[0066] A preparation process for an antibacterial and water-resistant composite leather for automotive trim, comprising the following steps:

[0067] Step 1, wash the leather embryo with ethanol and pure water alternately at least twice to remove surface stains, and then place it in a drum with 0.5% formic acid solution and rotate it for 0.2h, after draining, add retanning agent solution Rotate in the drum for 0.2h, after draining water again, add neutralizing solution and rotate in the drum for 0.3h, add neutralizing liquid and rotate in the drum for 0.3h after draining for the third time, after draining for the fourth time, put the skin embryo Put it under the condition of 75~90°C and dry it until the water content is 35% to obtain the pre-treated skin embryo; wherein, the retanning agent solution is obtained by mixing acrylic resin retanning agent and deionized water according to the mass ratio of 3:100 , the neutralizing solution is obtained by mixing the neutralizing reta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com