Automatic monitoring method for layered settlement of vacuum preloading foundation

A layered settlement and foundation technology, which is applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems of bad weather, bending and deformation of settlement pipes, and inconvenient data collection, so as to ensure continuity and real-time, Reduce monitoring costs and facilitate data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

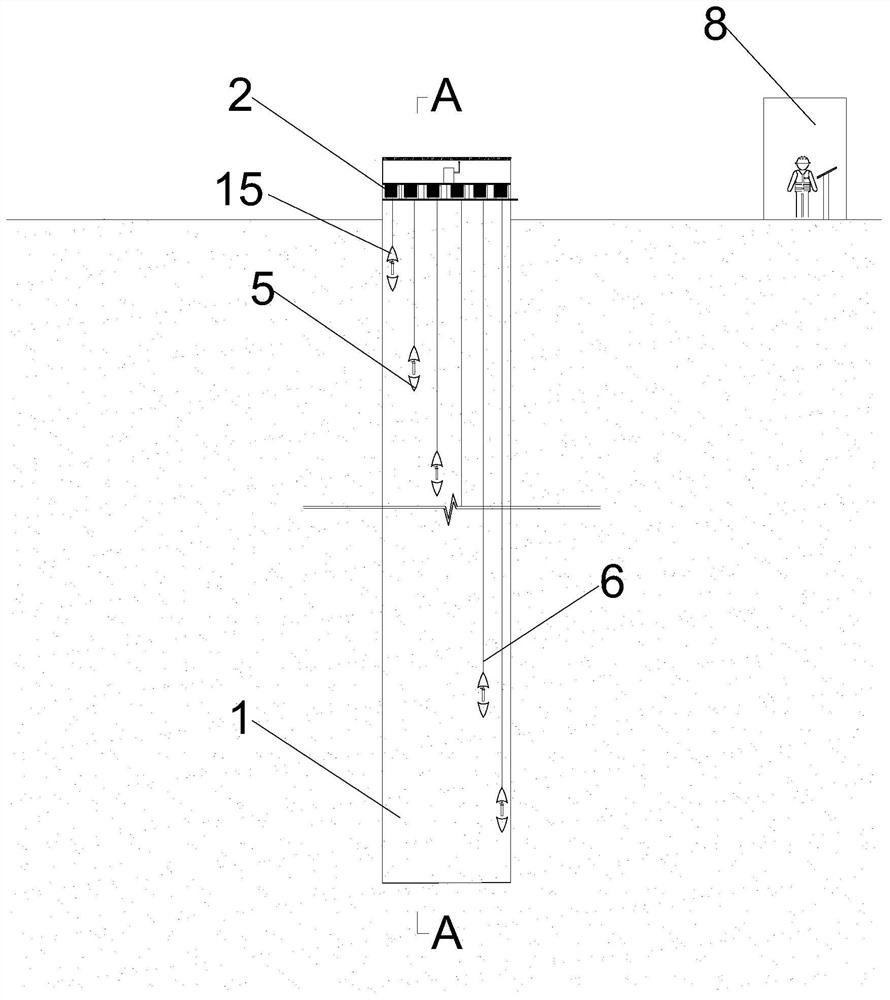

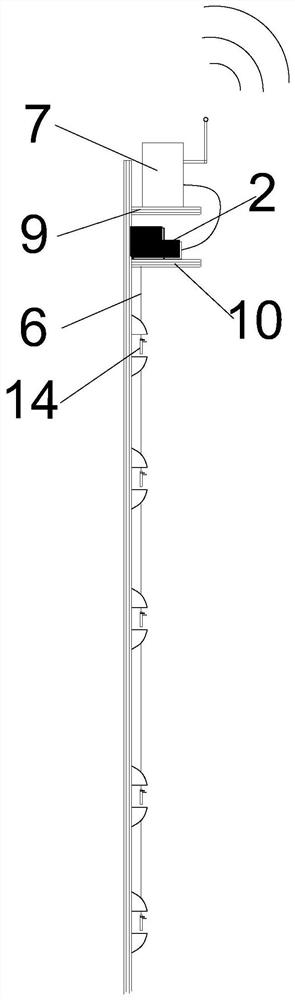

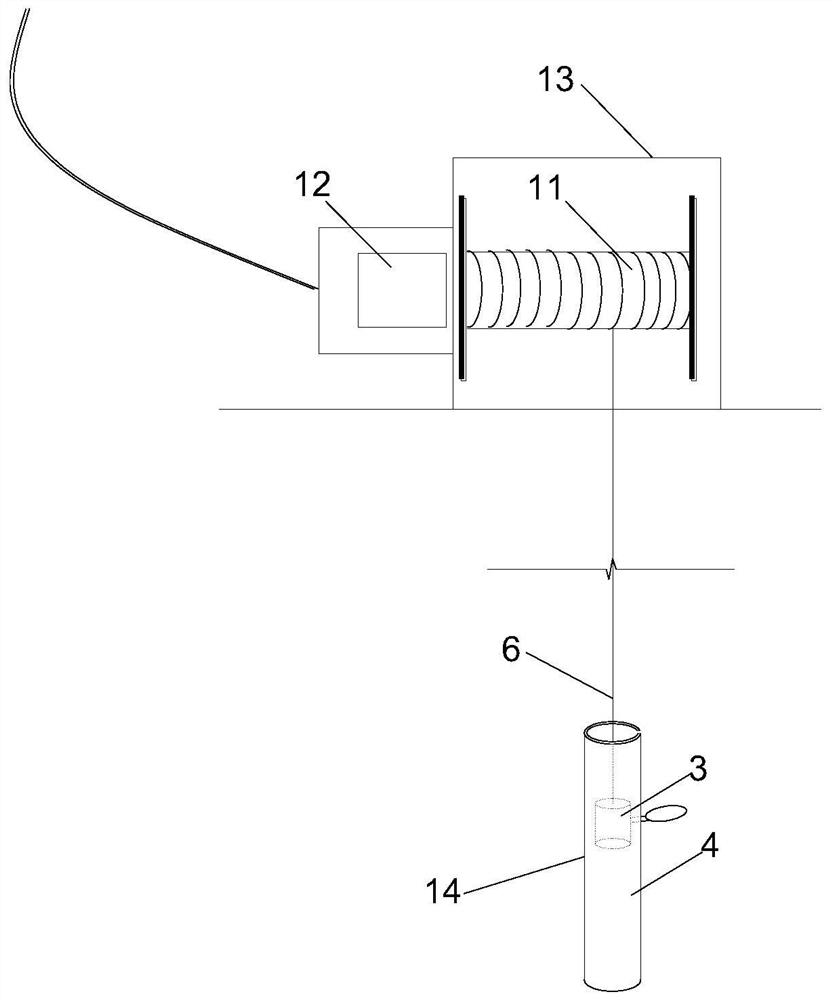

[0043] As shown in the figure, an automatic monitoring device for layered subsidence of a vacuum preloaded foundation according to the present invention includes: an installation substrate 1, a signal transmitting device 7, a signal collection terminal 8, and a plurality of sensing units 14 for sensing layered subsidence and a plurality of measuring units 2 connected to the sensing unit 14 for measuring the displacement of the sensing unit 14;

[0044] A plurality of induction units 14 are installed on the installation substrate 1, and the spacing between two adjacent induction units 14 in the vertical direction is the same, and each induction unit 14 includes a sliding cylinder 4 and a sliding cylinder. 4 inside the wiring ring 3, the outer wall of the slider 4 is fixed on the installation substrate 1, the top of the slider 4 is open, and a chute is opened on one side of the slider 4, and the wiring ring 3 The movable end extends out of the chute and cooperates with the chute...

Embodiment 2

[0058] On the basis of Embodiment 1, the separation distance and quantity of the plurality of sensing units 14 are determined according to monitoring design requirements.

[0059] Furthermore, the surface of the bobbin 11 is threaded, which drives the bobbin 11 to rotate when the pull cord 6 is displaced, and at the same time makes the encoder 12 output an electrical signal with the rotation of the bobbin 11 .

Embodiment 3

[0061] A method for using an automatic monitoring device for vacuum preloaded ground layer settlement of the present invention, comprising the following steps:

[0062] (1) Determine the length and width of the installation substrate 1 according to the depth of each soil layer of the foundation to be monitored according to the specifications and design requirements;

[0063] (2) According to the design requirements, use GPS to determine multiple monitoring points for the layered settlement of the foundation soil;

[0064] (3) Determine the embedding depth and interval (usually 2m) of the induction unit 14 according to the design requirements, and then weld the first clamping plate 9 and the second clamping plate 10 on the mounting substrate 1, so that the first clamping plate 9 and the second clamping plate 9 The clamping plates 10 are parallel to each other and extend outward, and the cap 15, the slider 4 and the boot 5 are welded on the installation substrate 1, and the cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com