Oil-electric hybrid brake device

A hybrid braking and driving device technology, applied in the direction of brake types, brake actuators, axial brakes, etc., can solve the problems of increasing the cost and volume of hydraulic power sources, long additional response time, etc., to avoid long-term high pressure state , fast brake response, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

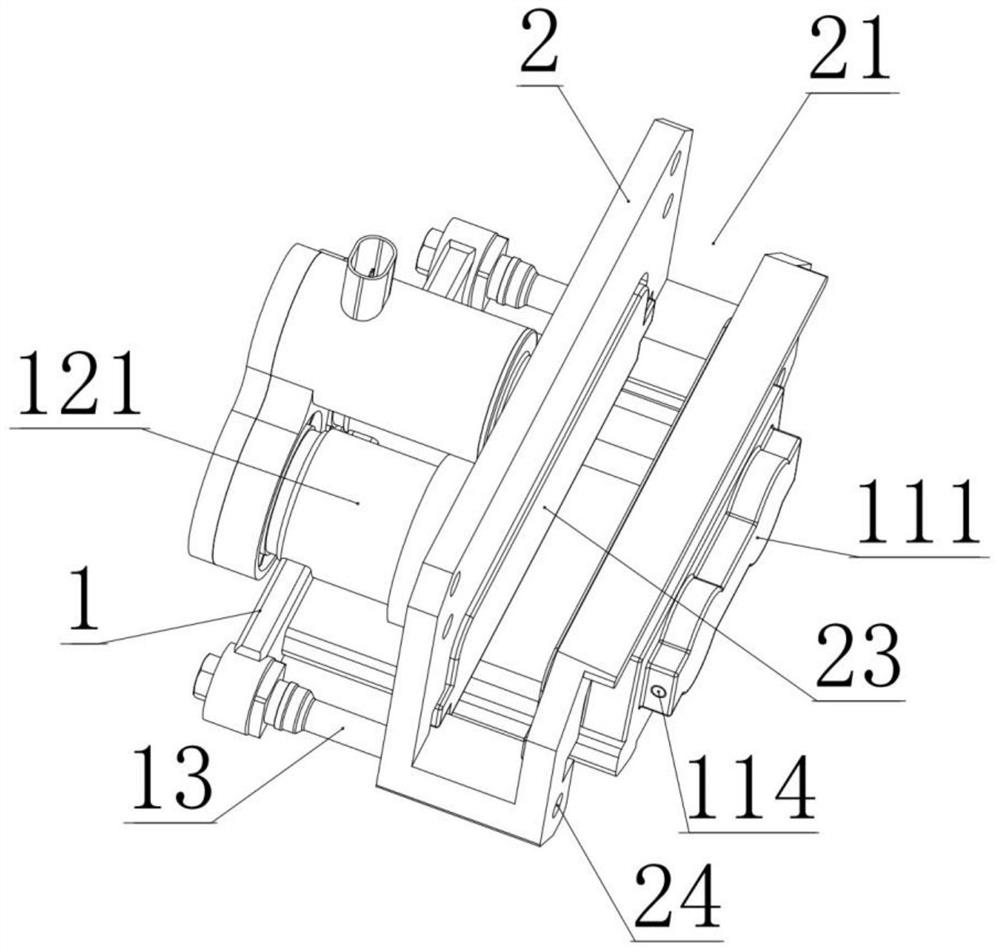

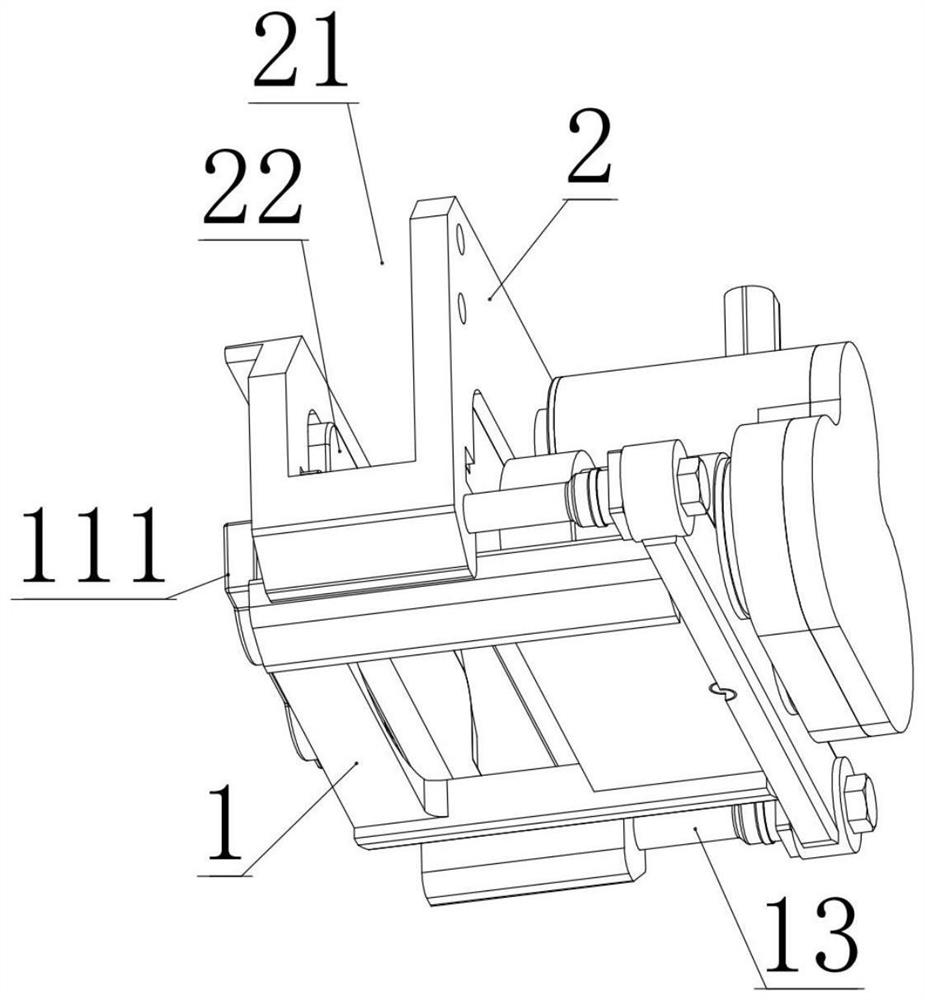

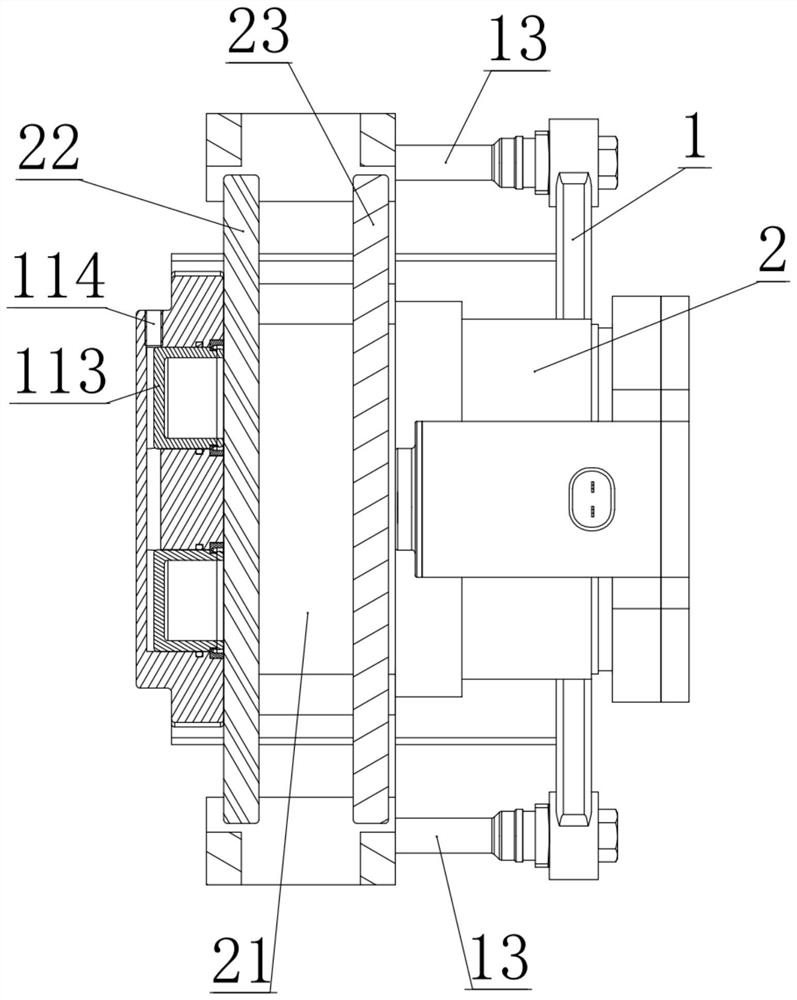

[0034] An oil-electric hybrid braking device, such as Figure 1 to Figure 8 As shown, it includes a caliper frame 1 and a caliper body 2 that is slidingly connected with the caliper frame 1; the caliper body 2 has a jaw 21 that can accommodate a brake disc; The plates are respectively recorded as the first friction plate 22 and the second friction plate 23, and the friction plates on both sides are slidably connected with the caliper body 2; on the pliers frame 1 and located on both sides of the caliper body 2, there are also hydraulic drive Device and electric driving device; the hydraulic driving device can push the first friction plate 22 to move toward the direction close to the second friction plate 23 , and the electric drive device can push the second friction plate 23 to move toward the direction close to the first friction plate 22 .

[0035] In this embodiment, the electric driving device has a self-locking function; the pushing speed of the electric driving device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com