Valve structure without valve rod and capable of resisting water hammer effect

A water hammer effect, valve stem technology, applied in the valve shell structure, valve operation/release device, valve fluid energy absorption device, etc., can solve the sealing surface product leakage, valve turbulence, rubber coating and Problems such as low adhesion of the cock base body, to achieve the effect of maintaining the overturned sealing, maintaining the sealing of the butt, and alleviating the water hammer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

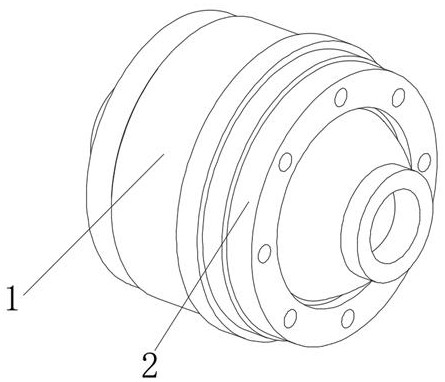

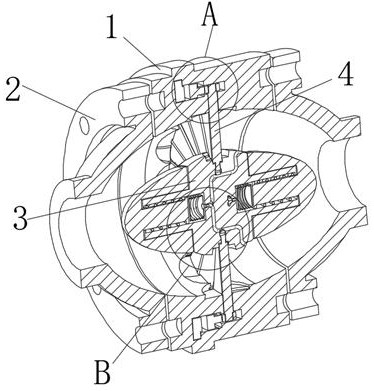

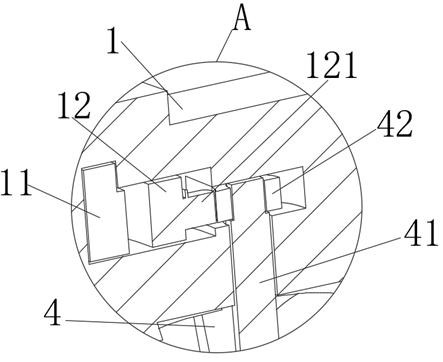

[0042] see Figure 1-9 , a valve structure with no valve stem anti-water hammer effect, including a valve body 1 and end caps 2 fixed on both sides of the valve body 1, a valve core 3 is arranged inside the valve body 1, and the gap between the valve core 3 and the inner wall of the valve body 1 A number of turning plates 4 are equiangularly divided. The turning plates 4 are fan-shaped structures. The axial position of the turning plates 4 is fixed with a rotating shaft 41. The valve body 1 and the valve core 3 are provided with bearing seats corresponding to the rotating shaft 41. One end of the rotating shaft 41 is fixed with an eccentric wheel 42, and the valve body 1 is slidably connected with a rubidium magnetic ring 12, and one side of the rubidium magnetic ring 12 is provided with a pressing block 121 corresponding to the eccentric wheel 42 one by one, and the valve body 1 is fixed with a The electromagnet 11 matched with the rubidium magnetic ring 12, the two sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com