Sintering method for reducing content of NOx in sintering flue gas in ignition stage

A technology of sintering flue gas and sintering method, applied in the field of sintering, which can solve the problems of lowering flame temperature, unfavorable sintering production, limited space and operation, etc., and achieves the effect of prolonging ignition time, improving sintering ignition layout, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail through examples below. These examples are only descriptions of the best implementation modes of the present invention, and do not limit the scope of the present invention in any way.

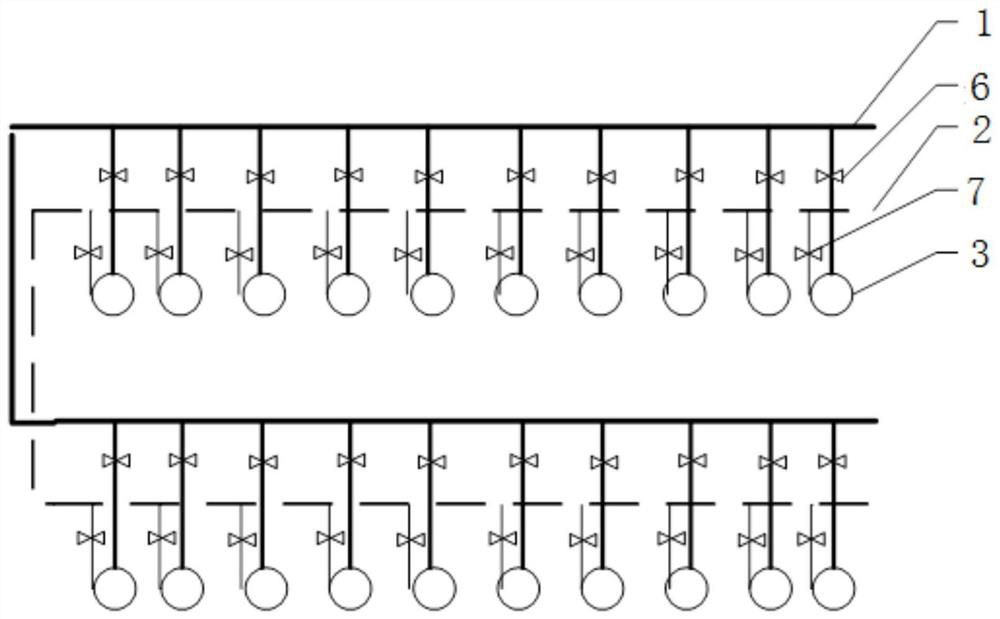

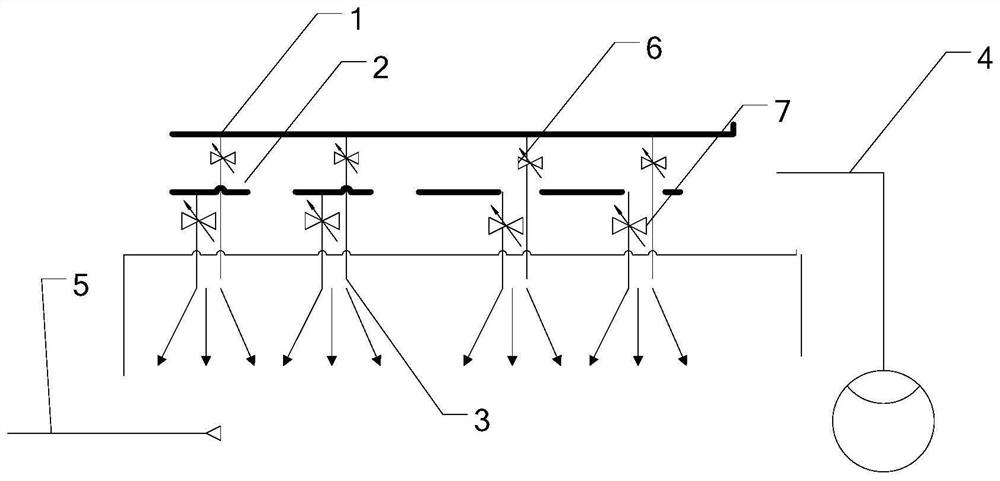

[0022] See image 3 , Figure 4 , the sintering igniter includes air main pipe 1, gas main pipe 2, ignition burner 3, infrared thermal image temperature detection system 4, air gas flow control system 5, air valve 6, gas valve 7; air main pipe 1 and gas main pipe 2 come from The air and gas enter the ignition burner 3 to be ignited, and the infrared thermal imaging temperature detection system 4 measures the temperature of each row of burners, judges the temperature signal and transmits the signal to the air gas flow control system 5, and the air gas flow control system 5 Control the air valve 6 and the gas valve 7 to adjust the flow and air-fuel ratio.

[0023] A sintering method for reducing the NOx content in the sintering flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com