Laser ultrasonic surface defect imaging noise reduction method based on improved wavelet threshold and VMD

A laser ultrasound and wavelet threshold technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, image enhancement, etc. It can solve problems such as unclear imaging and achieve high signal-to-noise ratio. , Optimize the imaging effect, the effect of short signal processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

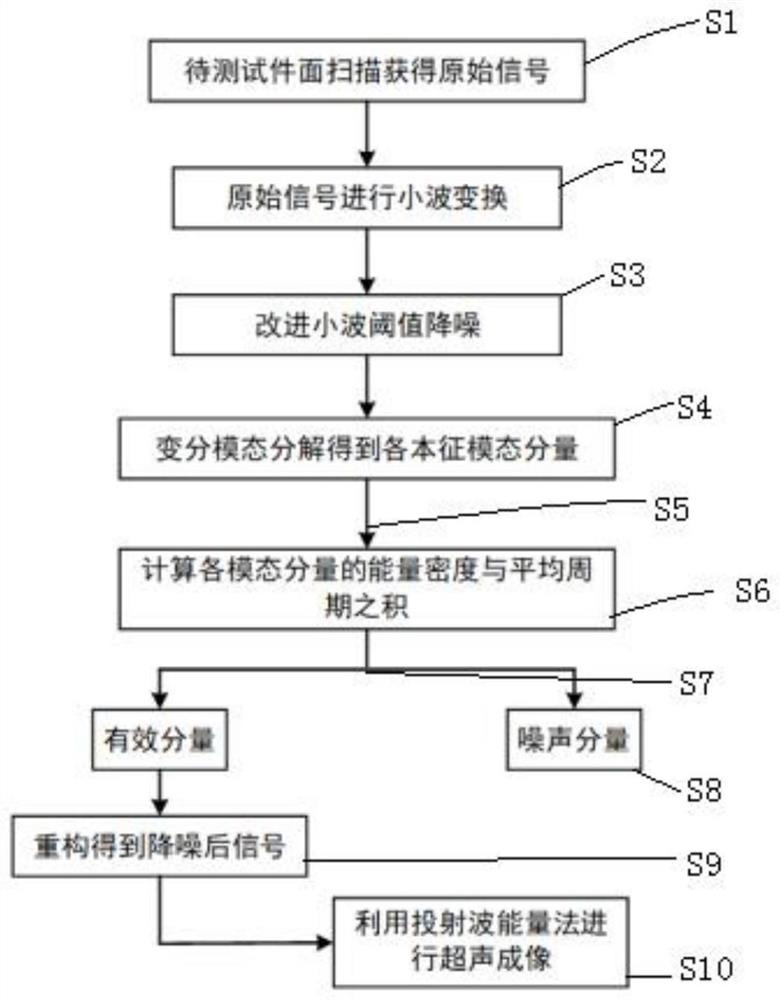

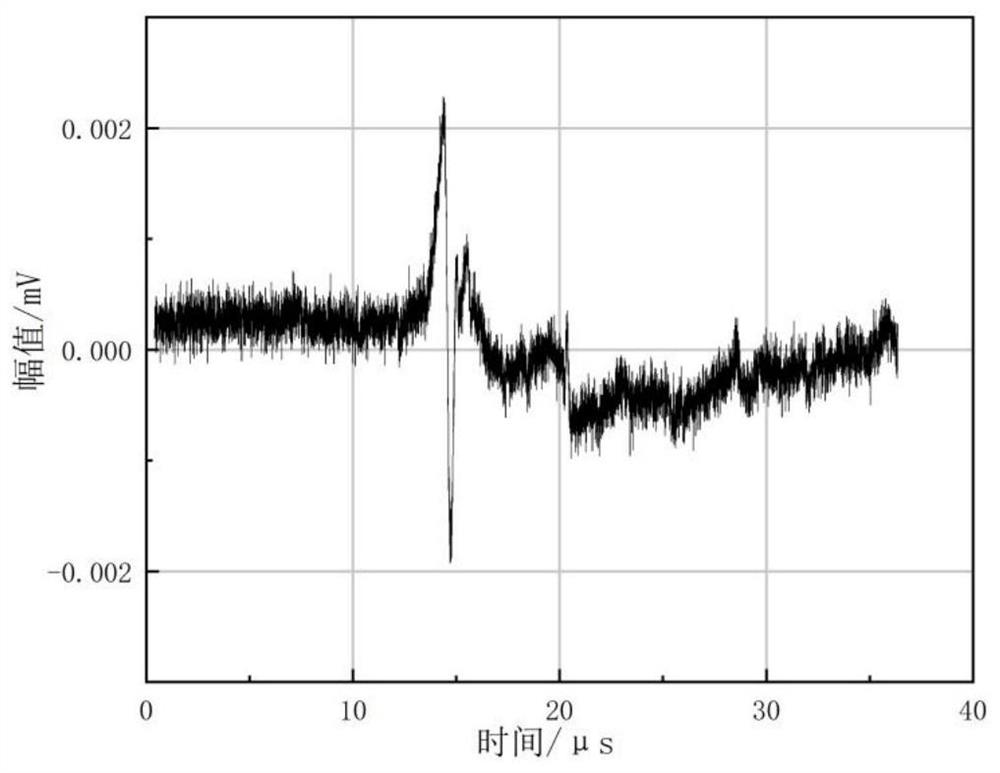

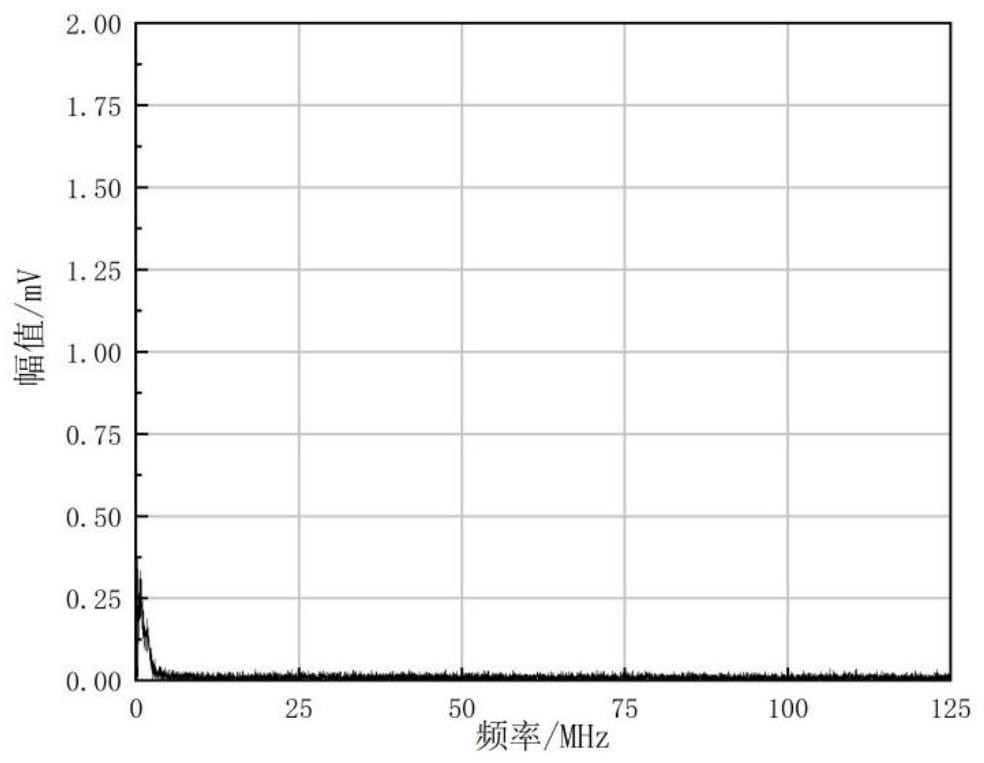

[0101] Embodiment: Step 1: Use a laser galvanometer scanning system and a laser interferometer to perform rapid laser ultrasonic surface scanning of the area to be tested on the test piece to obtain the original signal of the laser ultrasonic.

[0102] Step 2: Perform wavelet decomposition on the laser ultrasonic signal obtained in step 1, select the sym7 wavelet as the wavelet base, and decompose the number of layers into 5 layers to obtain detail components and approximate components.

[0103] Step 3: Hard threshold and soft threshold The wavelet threshold function is widely used, but there are certain limitations. The hard threshold function can retain more peak features of the original signal, but the hard threshold function is discontinuous at the threshold ± T, so that in There will be a certain oscillation phenomenon when reconstructing the signal; the soft threshold function is continuous at ±T, but it will cause a constant error between and, making the mean square erro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com