Flexible mineral insulated fireproof cable

A mineral insulated, fire-resistant cable technology, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problems of fillers, high cable cores, and easy deformation, etc., to improve heat dissipation, ensure fire protection efficiency, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Through the operation of the rotating column 10 of the stranding equipment, a plurality of insulated wire cores are stranded to form a cable core, and the cable core is cooled and cooled, and at the same time, the magnetic interference test is performed on the cable core by a spark tester. The cooled cable core, the fire-proof and heat-insulating filling layer 4 is one of metal hydrate aluminum hydroxide and aluminum hydroxide; the metal hydrate degradation temperature is about 350 degrees Celsius, and the heat transfer is lower than Celsius, and the metal hydrate will Free water is released, and when heat is transferred to the metal hydrate at 350 degrees Celsius, a large amount of water molecules will be released, absorbing a large amount of heat, and reducing the internal temperature of the cable. When the water molecules are completely released, the metal hydrate will form a porous medium compound, and the porous medium will It has excellent heat insulation performan...

Embodiment 2

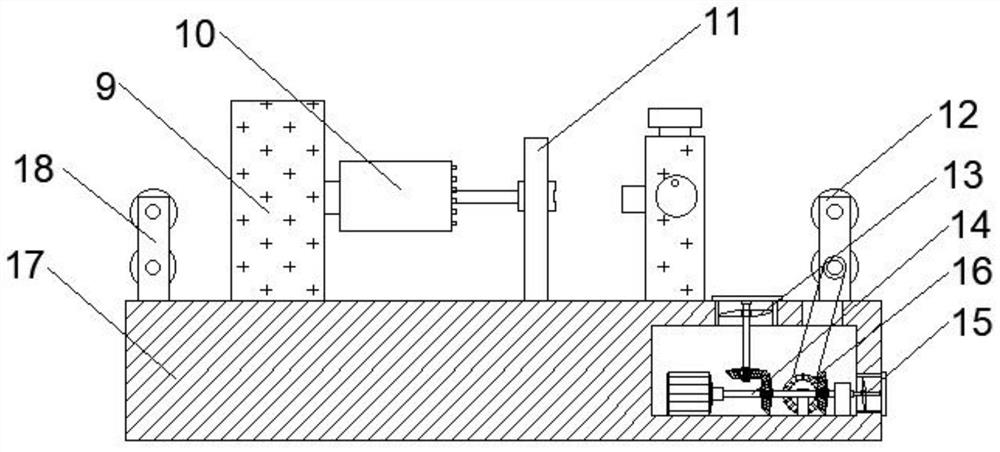

[0052] The above-mentioned wire twisting equipment includes a base 17, the middle part of the top surface of the base 17 is fixedly equipped with a fixed deck 9, and one side of the fixed deck 9 is provided with a twisting mechanism and a compression deck, and the two ends of the top surface of the base 17 The first driving mechanism 18 and the second driving mechanism 12 are fixedly installed respectively, and a cavity is opened inside the base 17, and a cooling mechanism 14 and a transmission mechanism 16 for driving the second driving mechanism 12 are arranged in the middle of the cavity.

[0053] The above-mentioned wire twisting mechanism includes a rotating column 10 that is in transmission connection with the fixed bracket 9 and a wire twisting reel 11 arranged on a base 17 .

[0054] One end of the above-mentioned base 17 close to the second driving mechanism 12 is provided with a second mounting hole, the top surface of the base 17 is provided with a first mounting hol...

Embodiment 3

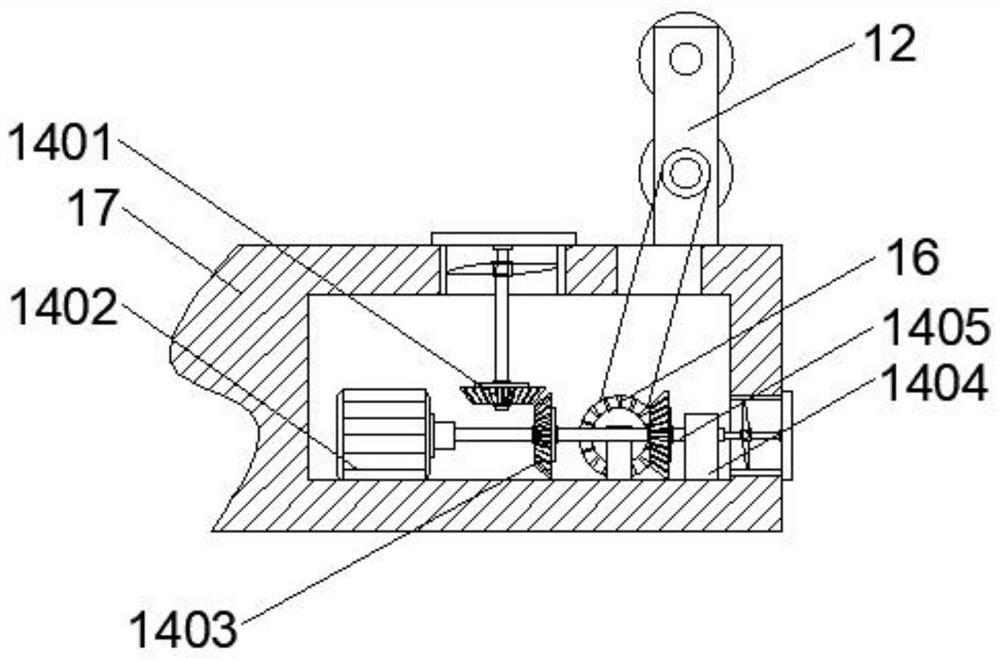

[0057] The above heat dissipation mechanism 14 includes a driving motor 1402 and a first limiting plate 1404 located at the bottom of the cavity, the output end of the driving motor 1402 is fixedly connected with a first transmission shaft 1405, and the first transmission shaft 1405 moves through the first limiting plate 1404 And it is fixedly connected with the fan shaft of the second fan 15, the second bevel gear 1403 is fixedly connected on the first transmission shaft 1405, the second bevel gear 1403 is meshed with the first bevel gear 1401, and the central axis of the first bevel gear 1401 is connected with the The fan shaft of the first blower fan 13 is fixedly connected; the first drive shaft 1405 is driven to run by the drive motor 1402, so that the second blower fan 15 runs to suck the air from the outside into the cavity, and then cooperates with the second bevel gear 1403 and the first bevel gear 1401 is meshed, so that the first fan 13 runs to take out the air in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com