Electrochemical device and electronic device

An electrochemistry, electrode pole piece technology, applied in the field of electrochemistry, can solve the problems of poor uniformity of pore size in the isolation layer, self-discharge, affecting the performance of lithium ion batteries, etc., to improve the degree of uniformity, improve rate performance and safety, The effect of improving the self-discharge problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097]

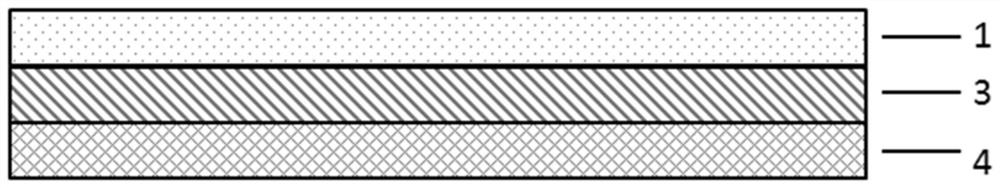

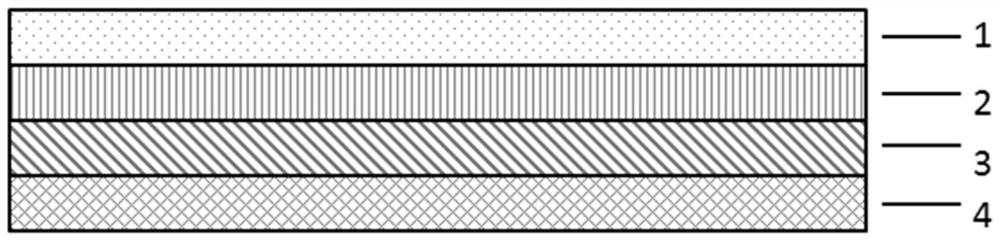

[0098] The negative active material graphite, conductive carbon black, and styrene-butadiene rubber were mixed according to the mass ratio of 96:1.5:2.5, and deionized water was added as a solvent to prepare a slurry with a solid content of 70%, and stirred evenly. The slurry was evenly coated on one surface of a copper foil with a thickness of 8 μm, and dried at 110° C. to obtain a negative electrode sheet.

[0099] After the above steps are completed, the single-side coating of the negative electrode sheet has been completed. Afterwards, these steps are also completed on the back of the pole piece in a completely consistent manner, that is, a double-sided coated negative pole piece is obtained. After the coating is completed, the pole piece is cut into (41mm×61mm) specifications for use.

[0100]

[0101] The positive electrode active material lithium cobaltate (LiCoO 2 ), conductive carbon black, and polyvinylidene fluoride (PVDF) in a mass ratio of 97.5︰1.0︰...

Embodiment 2、 Embodiment 3、 Embodiment 4

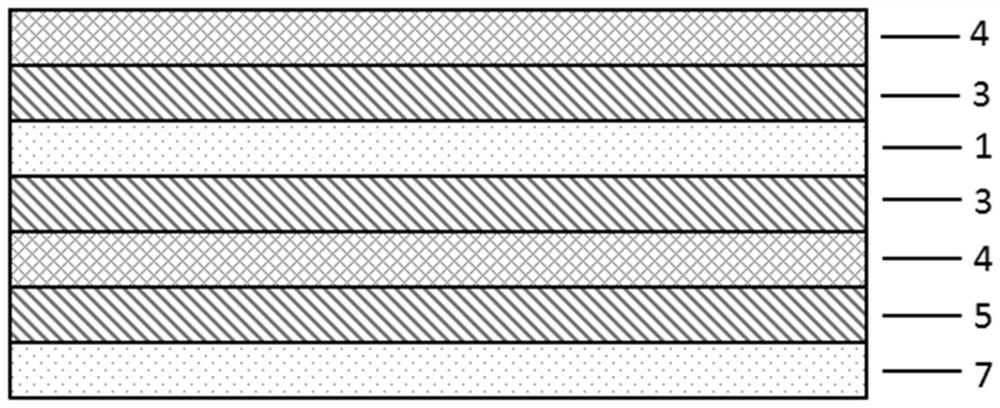

[0111] Except in , the fiber separation layer was prepared according to the process parameters shown in Table 1, so that the average pore size, thickness, porosity, tortuosity, and tortuosity of the obtained fiber separation layer were as shown in Table 1. Except that shown, all the other are identical with embodiment 1.

Embodiment 5

[0113] Except that is different from Example 1, the others are the same as Example 1.

[0114]

[0115] Disperse silicon dioxide (average particle size of 2 μm) in a mixed solvent of DMF:acetone=7:3, and stir until the viscosity of the slurry is stable, and obtain slurry A with a solid content of 40% as a raw material.

[0116] Spray the spinning solution and slurry A on the surface of the positive electrode active material layer of the positive electrode sheet by electrospraying, so that the inorganic particle silica is prepared on the surface of the positive electrode sheet synchronously, and fibers with inorganic fillers in the gaps between the polymer fibers are obtained. Isolation layer. The thickness, average pore diameter, thickness, porosity, tortuosity, tortuosity, etc. of the fiber isolation layer are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com