Sponge cat litter raw material and preparation method thereof

A technology for cat litter and raw materials, which is applied to sponge cat litter raw materials, sponge cat litter raw material preparation, and cat litter preparation fields, can solve the problems of large odor, odor removal and unsatisfactory comfort, and troublesome and laborious cleaning of cat litter boxes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

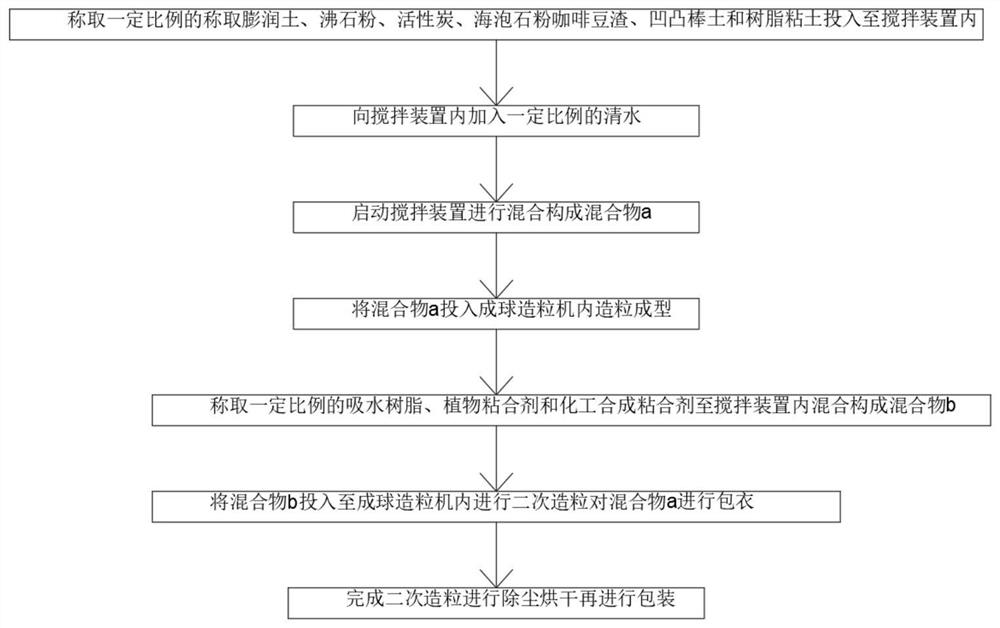

Method used

Image

Examples

Embodiment 1

[0075] 10% bentonite; 7% bamboo charcoal powder; 5% coffee bean dregs; 10% zeolite powder; 10% sepiolite powder; 10% attapulgite; 15% resin clay; 15% water-absorbing resin; Binder 3%.

[0076] Weigh 10% of bentonite, 10% of zeolite powder, 7% of bamboo charcoal powder, 10% of sepiolite powder, 5% of coffee bean dregs, 10% of attapulgite and 15% of resin clay and put them into the stirring device;

[0077] Step 2: Add 10% clear water into the stirring device;

[0078] Step 3: Start the stirring device to mix and stir 10% bentonite, 10% zeolite powder, 7% bamboo charcoal powder, 10% sepiolite powder, 5% coffee bean dregs, 10% attapulgite, 15% resin clay and 10% clear water 2 -3h constitutes mixture a;

[0079] Step 4: Put the stirred mixture a into a pelletizing machine for granulation;

[0080] Step 5: Weigh 15% of the water-absorbing resin, 5% of the plant adhesive, and 3% of the chemical synthetic adhesive, and put them into the stirring device, and mix and stir for 2-3 ho...

Embodiment 2

[0088] Bentonite 50%; bamboo charcoal powder 8%; coffee bean dregs 3%; zeolite powder 5%; sepiolite powder 5%; attapulgite 5%; resin clay 5%; water-absorbing resin 5%; plant adhesive 2%; Binder 2%.

[0089] Weigh 50% of bentonite, 5% of zeolite powder, 8% of bamboo charcoal powder, 5% of sepiolite powder, 3% of coffee bean dregs, 5% of attapulgite and 5% of resin clay and put them into the stirring device;

[0090] Step 2: Add 10% clear water into the stirring device;

[0091] Step 3: Start the stirring device to mix and stir 50% of bentonite, 5% of zeolite powder, 8% of bamboo charcoal powder, 5% of sepiolite powder, 3% of coffee bean dregs, 5% of attapulgite, 5% of resin clay and 10% of clear water 2 -3h constitutes mixture a;

[0092] Step 4: Put the stirred mixture a into a pelletizing machine for granulation;

[0093] Step 5: Weigh 5% of the water-absorbing resin, 2% of the plant adhesive, and 2% of the chemical synthetic adhesive, and put them into a stirring device, ...

Embodiment 3

[0098] Bentonite 25%; Bamboo Charcoal Powder 7%; Coffee Bean Dregs 3.5%; Zeolite Powder 7.5%; Sepiolite Powder 7.5%; Attapulgite 7.5%; Resin Clay 10%; Binder 3.5%.

[0099] Weigh 25% of bentonite, 7.5% of zeolite powder, 7% of bamboo charcoal powder, 7.5% of sepiolite powder, 3.5% of coffee bean dregs, 7.5% of attapulgite and 10% of resin clay and put them into the stirring device;

[0100] Step 2: Add 15% clear water to the stirring device;

[0101] Step 3: Start the stirring device to mix and stir 25% of bentonite, 7.5% of zeolite powder, 7% of bamboo charcoal powder, 7.5% of sepiolite powder, 3.5% of coffee bean dregs, 7.5% of attapulgite, 10% of resin clay and 15% of clear water 2 -3h constitutes mixture a;

[0102] Step 4: Put the stirred mixture a into a pelletizing machine for granulation;

[0103] Step 5: Weigh 10% of the water-absorbing resin, 3.5% of the plant adhesive, and 3.5% of the chemical synthetic adhesive, and put them into the stirring device, and mix and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com