Rapid purifying and filtering system for cutting fluid and purifying method

A filtration system, cutting fluid technology, applied in chemical instruments and methods, maintenance and safety accessories, solid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

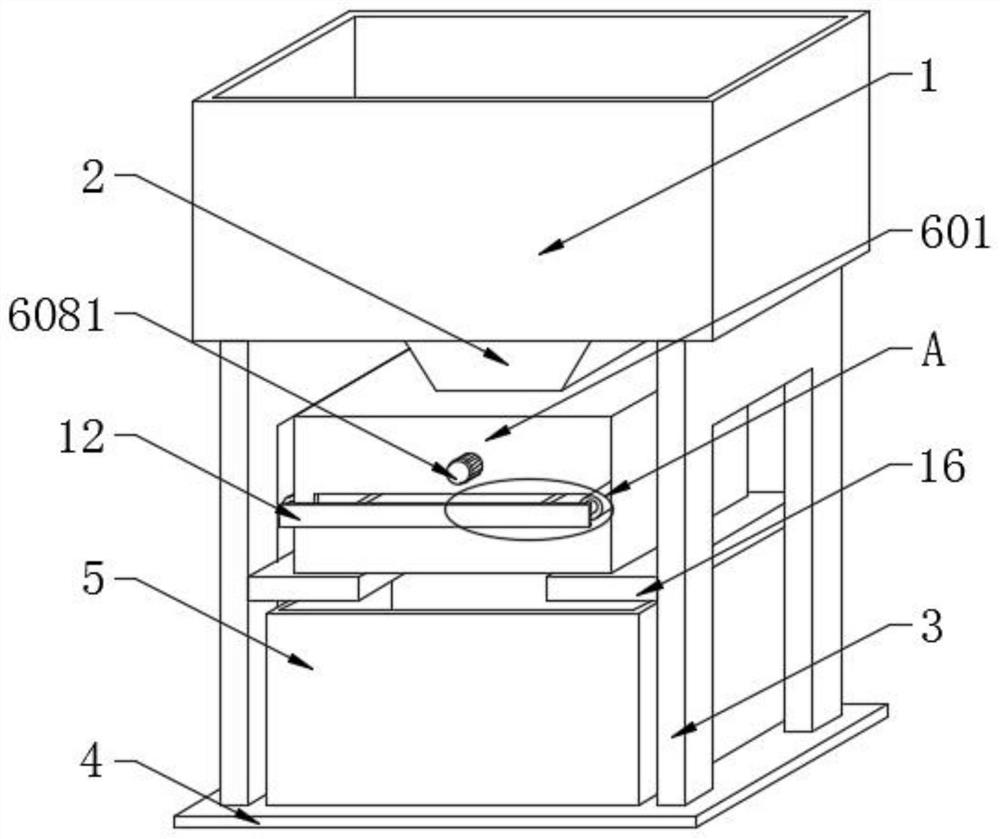

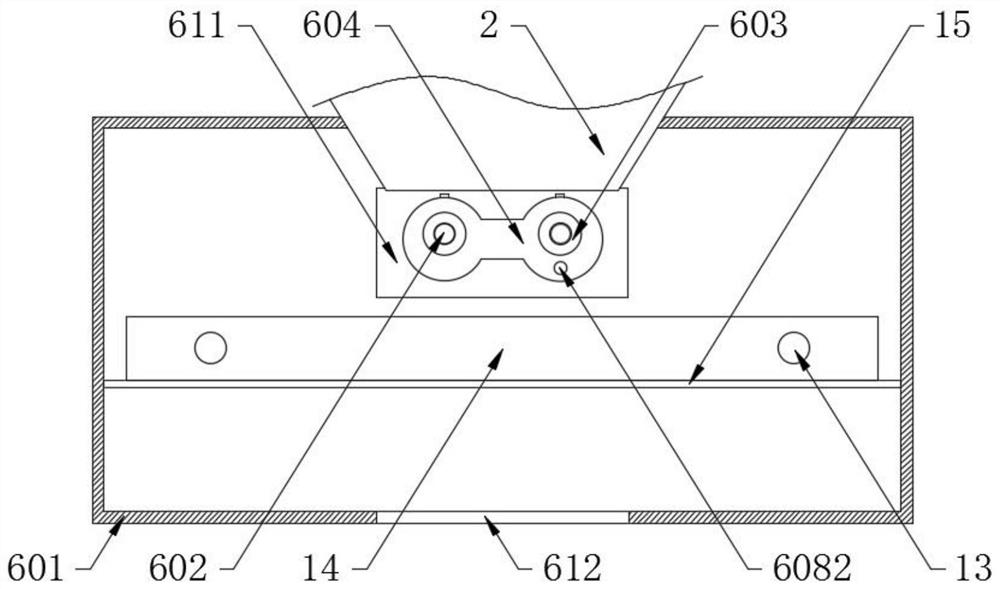

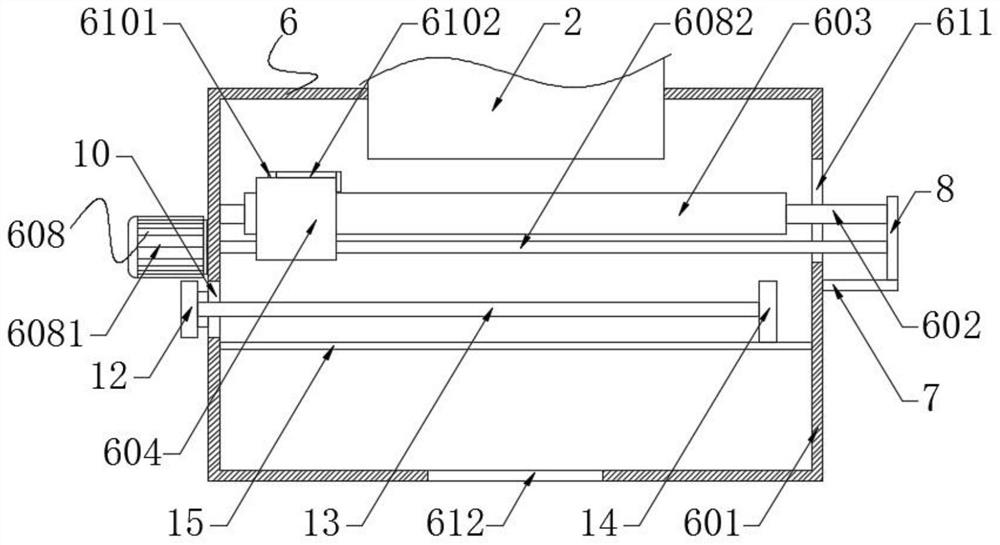

[0037] See Figure 1-10 The present invention provides a technical solution: a rapid purification filter system of a chip liquid, including a liquid storage tank 1 and a conveying tube 2 disposed below the reservoir pool 1, and a control valve is provided on the conveying tube 2, a reservoir 1 The bottom symmetry is fixedly connected to the bracket 3, and the bottom plate 4 is fixed between the bottoms of the two brackets 3, and the top portion of the bottom plate 4 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com