Forging and pressing device for producing aluminum alloy plates

An aluminum alloy sheet and forging technology, applied in forging/pressing/hammer devices, forging presses, forging presses, etc., can solve the problem of inconvenient removal of aluminum alloy sheets, displacement of forging lines or holes and grooves of aluminum alloy sheets, affecting processing efficiency. and other problems, to achieve the effect of improving the fixing strength, improving the precision of forging and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

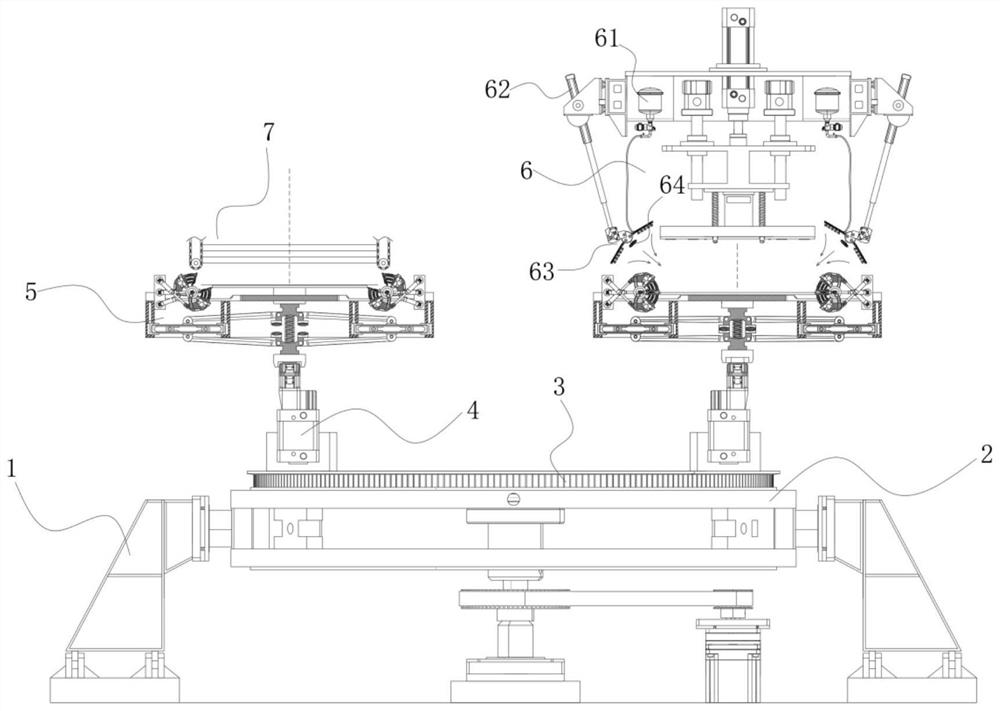

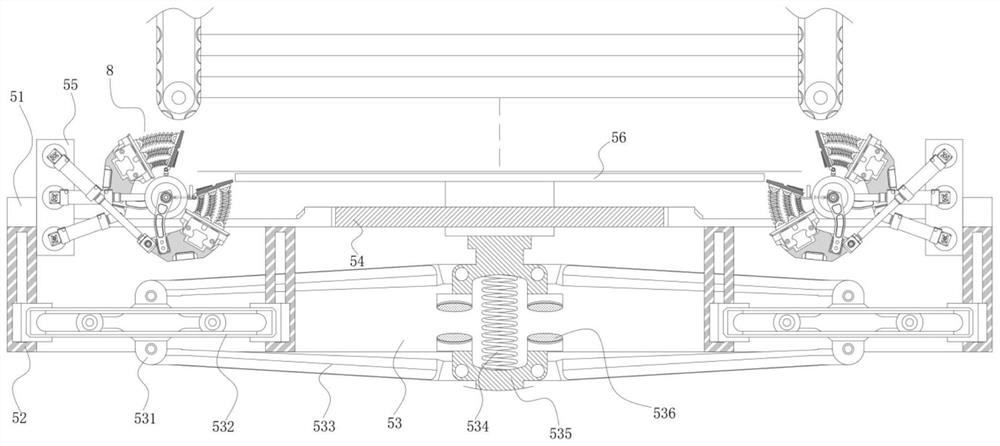

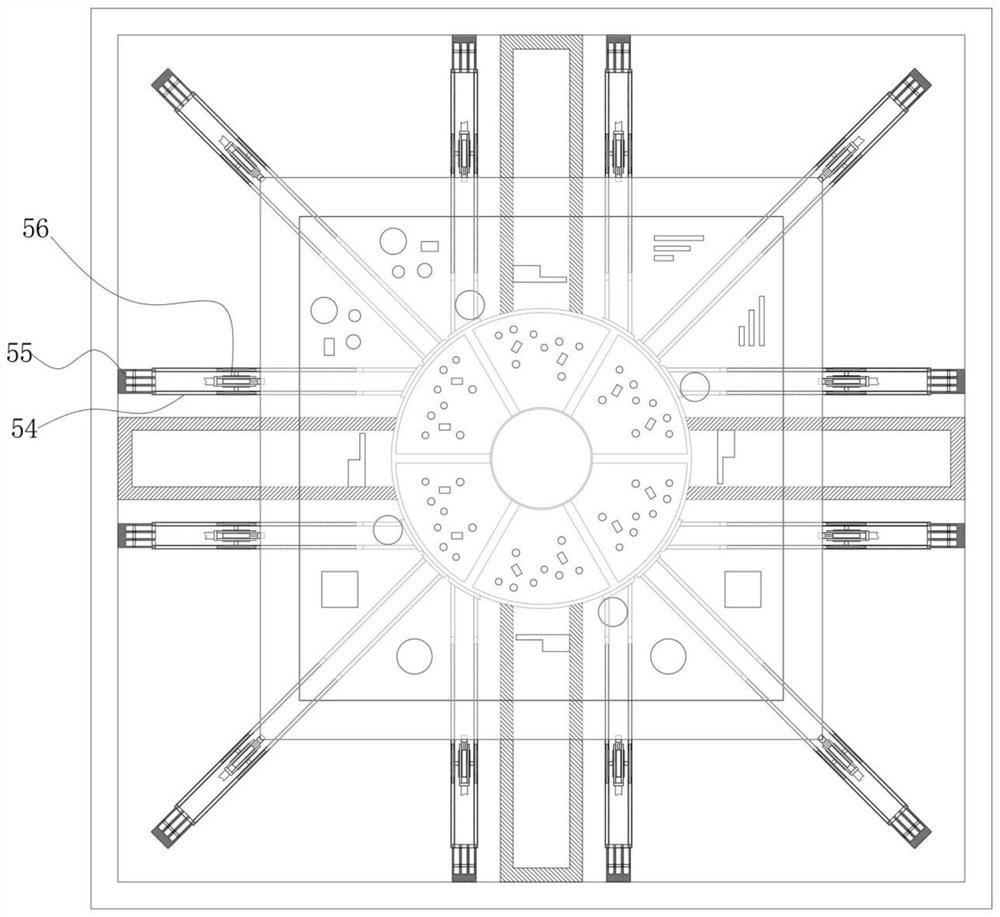

[0042] refer to Figure 1-5 , the present invention provides a technical solution: a forging device for producing aluminum alloy plates, which includes a workbench 1, a horizontal rotation drive device 2, a pressing device 5, a forging device 6, a feeding device 7 and a lifting support element 4 , a horizontal rotation drive device 2 is installed in the workbench 1, a horizontal rotation frame 3 is installed on the horizontal rotation drive device 2, and a lifting support element 4 is installed on the horizontal rotation frame 3, arranged in a circular arrangement Four groups, each group is equipped with a pressing and pulling device 5 on the lifting support element 4;

[0043] The feeding device 7 is installed above the left pressing and pulling device;

[0044] The forging device 6 is installed above the right pressing and pulling device.

[0045] In this embodiment, the feeding device 7 is composed of a conveyor belt arranged longitudinally and parallel to the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com