Baking oven automatic control system

An automatic control system and baking oven technology, applied in the field of baking ovens, can solve problems such as large maintenance projects, inconvenient maintenance, and potential safety hazards, and achieve the effects of easy maintenance, space saving, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples.

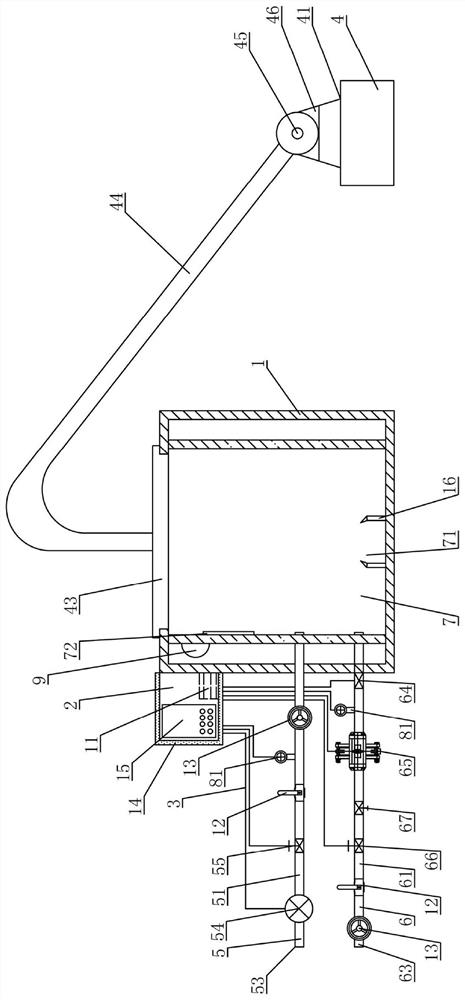

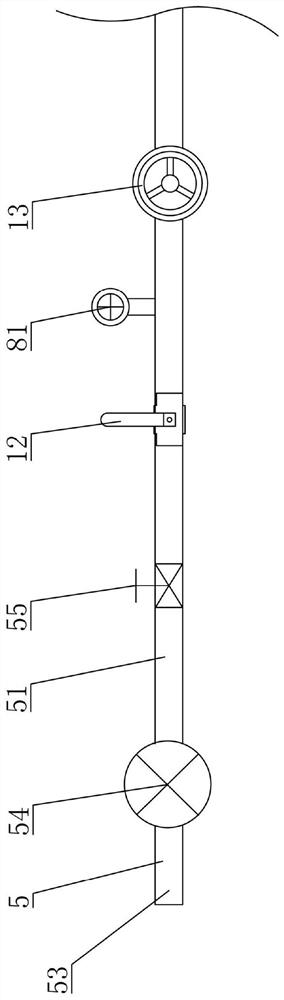

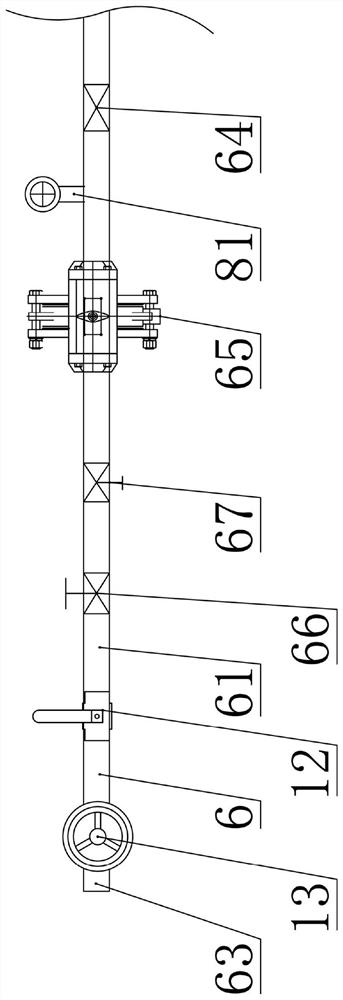

[0031] combine Figure 1-Figure 4 shown;

[0032] An automatic control system for a baking oven, comprising a furnace body 1 and an electric control cabinet 2, and a connection circuit 3 is provided between the furnace body 1 and the electric control cabinet 2, the connection circuit 3 includes an end cover lifting power unit 4, a combustion air Supply and control unit 5, gas supply and control unit 6, combustion condition control and real-time monitoring unit 7 and pressure detection unit 8, end cover lifting power unit 4 includes a drive assembly 41 arranged on the furnace body 1 and is used for control and The drive control module 42 that drives the end cover 43 to lift, the drive assembly 41 includes an end cover 43 arranged on the upper end of the furnace body 1, a cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com