Method for deeply removing arsenic and mercury in crude selenium

A crude selenium and removal technology is applied in the directions of element selenium/tellurium, process efficiency improvement, chemical industry, etc., can solve the problems of insignificant mercury removal effect and low mercury content, etc., and achieves the effects of low cost and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

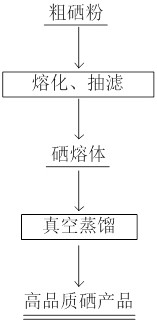

Image

Examples

Embodiment 1

[0021] Weigh 200g of crude selenium whose main components are Se 96%, As 0.42%, and Hg 0.33%, put it on the stainless steel screen with an aperture of 500 mesh, put a receiving crucible under the screen, and put them together in the reaction kettle for heating and melting , after the temperature in the reactor reaches 250°C, that is, after the thick selenium inside is melted, vacuumize under the reactor, take it out after 30 minutes of heat preservation, and obtain 164.5g of selenium melt in the receiving basin; put the obtained selenium melt into the Vacuum distillation was carried out in a vacuum furnace with a vacuum degree of 1 Pa, a temperature of 270° C., and a heat preservation of 2 hours to finally obtain 162.9 g of selenium.

[0022] ICP-AES was used to quantitatively analyze the chemical composition of impurity elements arsenic and mercury. The content of arsenic and mercury in selenium products was 3.75ppm and 287ppm respectively, and the removal rates reached 99.91%...

Embodiment 2

[0024] Weigh 200g of crude selenium whose main components are Se 96%, As 0.42%, and Hg 0.33%, put it on the stainless steel screen with an aperture of 1000 mesh, put a receiving crucible under the screen, and put them together in the reaction kettle for heating and melting , after the temperature in the reactor reaches 350°C, that is, after the thick selenium in the inside melts, vacuumize under the reactor, take it out after 30 minutes of heat preservation, and obtain 159.7g of selenium melt in the receiving basin; then put the obtained selenium melt into Vacuum distillation was carried out in a vacuum furnace with a vacuum degree of 30 Pa and a temperature of 400° C. for 2 hours to obtain 157.6 g of selenium.

[0025] ICP-AES was used to quantitatively analyze the chemical composition of impurity elements arsenic and mercury. The content of arsenic and mercury in selenium products was 4.23ppm and 275ppm respectively, and the removal rates reached 99.90% and 91.67% respectivel...

Embodiment 3

[0027] Take by weighing the thick selenium 200g that main component is Se 96%, As 0.42%, Hg 0.33%, be placed on the stainless steel screen cloth of 1500 meshes of aperture, put one deck screen cloth again below the screen cloth, then put a receiving crucible below, will They are put together in the reaction kettle and heated and melted. After the temperature in the reaction kettle reaches 500°C, that is, after the crude selenium inside is melted, vacuumize under the reaction kettle, take it out after keeping warm for 30min, and obtain 156.8g of selenium melt in the receiving basin ; Then the obtained selenium melt was placed in a vacuum furnace for vacuum distillation, the vacuum degree was 10Pa, the temperature was 500° C., and the temperature was kept for 2 hours, and finally 154.2 g of selenium was obtained.

[0028] ICP-AES was used to quantitatively analyze the chemical composition of impurity elements arsenic and mercury. The content of arsenic and mercury in selenium pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com