Antibacterial and ultraviolet-proof cotton yarn

A technology of anti-ultraviolet and cotton yarn, which is applied in the direction of textile, lamination, application, etc., can solve the problems of inability to meet antibacterial requirements, weak tensile performance, and lack of anti-ultraviolet rays, and achieve increased antibacterial protection effect, high volatility, Increase the effect of refraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

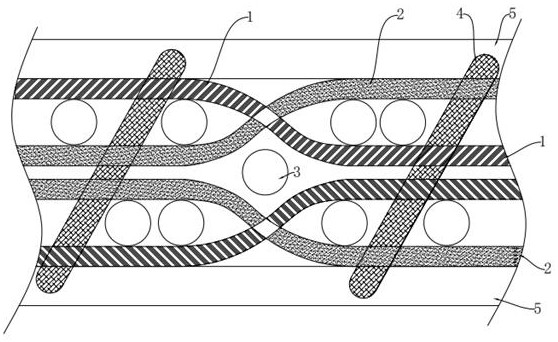

Image

Examples

Embodiment 1

[0027] An antibacterial and anti-ultraviolet cotton yarn of the present invention is characterized in that it comprises the following components by weight: 25 parts of cotton fiber, 15 parts of jasmine, 20 parts of wood fiber, 12 parts of photosensitive resin, 28 parts of activated carbon, 25 parts of tea leaves, and 12 parts of aloe and tea tree essential oil 12 parts.

[0028] A kind of preparation method of antibacterial and anti-ultraviolet cotton yarn of the present invention, comprises the following steps:

[0029] Step 1: Take jasmine flowers, sort and remove impurities, use mechanical knocking, comb and separate the filaments, add hydrogen peroxide to prepare alkali cellulose, yellow the alkali cellulose, dissolve it to make spinning slurry, add wood fiber to mix, static Place for 3h, and produce jasmine blended yarn by wet spinning;

[0030] Step 2: Take the tea leaves, put the tea leaves into a high-pressure container and pressurize them, decolorize and deoil the te...

Embodiment 2

[0039] An antibacterial and anti-ultraviolet cotton yarn of the present invention is characterized in that it comprises the following components by weight: 23 parts of cotton fiber, 11 parts of jasmine, 15 parts of wood fiber, 11 parts of photosensitive resin, 22 parts of activated carbon, 20 parts of tea, 14 parts of aloe and tea tree essential oil 9 parts.

[0040] A kind of preparation method of antibacterial and anti-ultraviolet cotton yarn of the present invention, comprises the following steps:

[0041] Step 1: Take jasmine flowers, sort and remove impurities, use mechanical knocking, comb and separate the filaments, add hydrogen peroxide to prepare alkali cellulose, yellow the alkali cellulose, dissolve it to make spinning slurry, add wood fiber to mix, static Place for 3h, and produce jasmine blended yarn by wet spinning;

[0042] Step 2: Take the tea leaves, put the tea leaves into a high-pressure container and pressurize them, decolorize and deoil the tea leaves, gr...

Embodiment 3

[0051] An antibacterial and anti-ultraviolet cotton yarn of the present invention is characterized in that it comprises the following components by weight: 22 parts of cotton fiber, 16 parts of jasmine, 15 parts of wood fiber, 13 parts of photosensitive resin, 22 parts of activated carbon, 15 parts of tea leaves, and 7 parts of aloe and tea tree essential oil 8 parts.

[0052] A kind of preparation method of antibacterial and anti-ultraviolet cotton yarn of the present invention, comprises the following steps:

[0053] Step 1: Take jasmine flowers, sort and remove impurities, use mechanical knocking, comb and separate the filaments, add hydrogen peroxide to prepare alkali cellulose, yellow the alkali cellulose, dissolve it to make spinning slurry, add wood fiber to mix, static Place for 3h, and produce jasmine blended yarn by wet spinning;

[0054] Step 2: Take the tea leaves, put the tea leaves into a high-pressure container and pressurize them, decolorize and deoil the tea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com