Premixed combustible gas turbulence and burning explosion process characteristic parameter testing device and method

A technology of characteristic parameters and testing devices, which is applied in measurement devices, aerodynamic testing, testing of machine/structural components, etc. The fine structure cannot be effectively captured, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

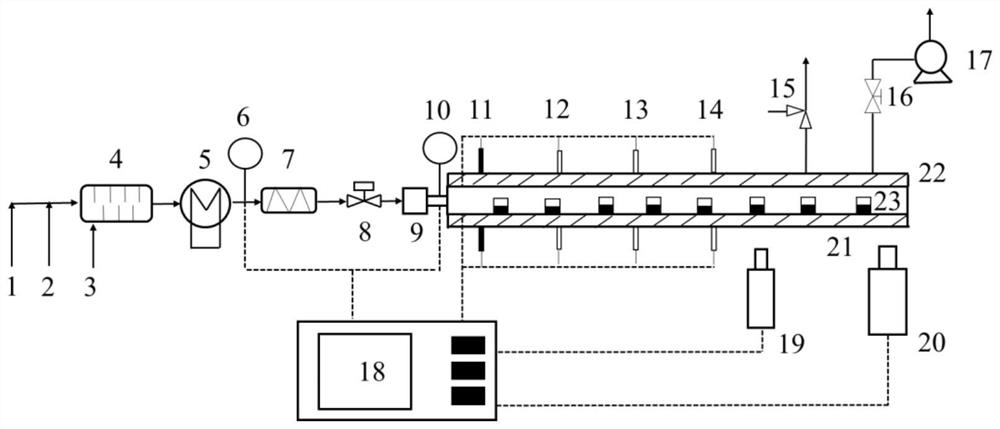

[0056] The combustible gas is hydrogen, the gas to be tested is a mixture of hydrogen and air, the initial temperature is set to 20°C, the initial pressure is set to 0.5MPa, the diameter of the inlet nozzle is 50mm, the length of the gas flow combustion tube is 2m, and the diameter is 200mm. First, purge the whole device with nitrogen, then close all valves, and vacuum the device. When the pressure change in the pipeline within 1 minute after the vacuum is completed, the system is considered to be well airtight.

[0057] Set the inlet flow of the hydrogen gas inlet pipeline to 10L / min, the air flow rate to 15L / min, set the temperature of the electric heater to 20°C, and control the inlet pressure to 0.5MPa through the pressure regulating valve. After the gas flow in the pipeline is stable, Turn on the ignition electrode, trigger data acquisition at the same time, observe the gas combustion status through the window on the gas flow combustion tube, and the data acquisition card...

Embodiment 2

[0059]The combustible gas is methane, the gas to be measured is a mixture of methane and air, the initial temperature is 100°C, the initial pressure is 1.0MPa, the diameter of the inlet nozzle is 5mm, the length of the gas flow combustion tube is 10m, and the diameter is 500mm. First, purge the whole device with nitrogen, then close all valves, and vacuum the device. When the pressure change in the pipeline within 1 minute after the vacuum is completed, the system is considered to be well airtight.

[0060] Set the inlet flow of the methane inlet pipeline to 20L / min, the air flow rate to 30L / min, set the temperature of the electric heater to 100°C, and control the inlet pressure to 1.0MPa through the pressure regulating valve. After the gas flow in the pipeline is stable, Turn on the ignition electrode, trigger data acquisition at the same time, observe the gas combustion status through the window on the gas flow combustion tube, and the data acquisition card of each sensor aut...

Embodiment 3

[0062] The combustible gas is methane, the gas to be tested is a mixture of methane and oxygen, the initial temperature is 50°C, the initial pressure is 0.2MPa, the diameter of the inlet nozzle is 20mm, the length of the gas flow combustion tube is 2m, and the diameter is 50mm. First, purge the whole device with nitrogen, then close all valves, and vacuum the device. When the pressure change in the pipeline within 1 minute after the vacuum is completed, the system is considered to be well airtight.

[0063] Set the inlet flow rate of the methane inlet pipeline to 12L / min, the oxygen flow rate to 15L / min, set the temperature of the electric heater to 50°C, and control the inlet pressure to 0.2MPa through the pressure regulating valve. After the gas flow in the pipeline is stable, Turn on the ignition electrode and trigger data collection at the same time. Observe the gas combustion status through the window on the gas flow combustion pipe. The data acquisition card of each senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com