Double-junction Ga2O3 device and preparation method thereof

A double junction and device technology, applied in the field of microelectronics, can solve the problems of inability to make breakthroughs in double junction semiconductor devices, slow ultraviolet light exploration and detection time, low carrier mobility, etc., to achieve excellent chip performance and improve stability. and electrical properties, the effect of improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

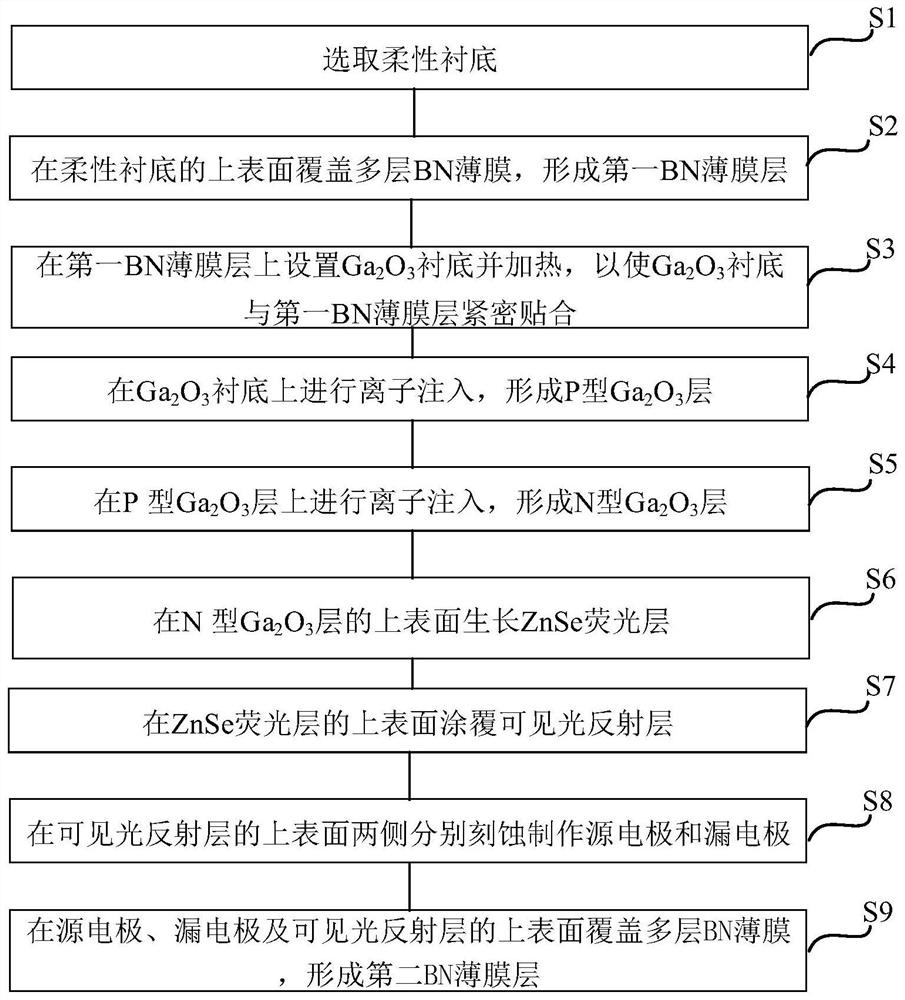

[0040] See figure 1 , figure 1 It is a kind of double-junction Ga 2 o 3 Flowchart of the fabrication method of the device. The double junction Ga 2 o 3 The preparation method of the device includes:

[0041] S1: Select a flexible substrate.

[0042] The flexible substrate is a PET (Polyethyleneterephthalate, polyester resin) flexible substrate with a thickness of 1-2 mm, a length of 2-3 cm, and a width of 2-3 cm. The thickness of the flexible substrate is selected to ensure that when strained, the strain can be precisely applied to the device.

[0043] S2: covering the upper surface of the flexible substrate with multiple layers of BN thin films to form a first BN thin film layer.

[0044] Specifically, a square BN film with 5-10 layers, a total thickness of 5-10 nm, and a size of about 80-120 μm is transferred and placed on the center of the upper surface of the PET flexible substrate using a transfer platform. The 5-10 layers of the BN thin film do not affect the ov...

Embodiment 2

[0059] On the basis of Embodiment 1, this embodiment describes in detail a double-junction Ga 2 o 3 Device fabrication method. See Figure 2a to Figure 2g , Figure 2a to Figure 2g It is a schematic diagram of the preparation process of a double-junction Ga2O3 device provided by the embodiment of the present invention. The preparation method of the present embodiment comprises:

[0060] Step 1: Select a flexible substrate 1, which is a PET flexible substrate with a thickness of 2mm, a length of 3cm, and a width of 3cm.

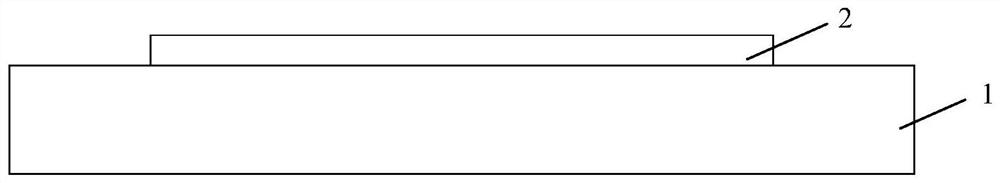

[0061] Step 2: Using a transfer platform, transfer a square BN film with a thickness of 5 layers, a total thickness of 5 nm, and a size of about 100 μm to the center of the above-mentioned PET flexible substrate to form the first BN film layer 2, as Figure 2a shown.

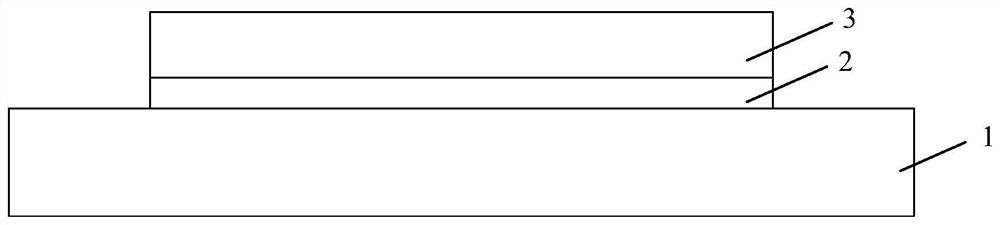

[0062] Step 3: Using the transfer platform to epitaxially grow the 150 thick Ga 2 o 3 The substrate 3 was transferred to the BN thin film and heated at 200°C to make the Ga 2 o 3 The s...

Embodiment 3

[0072] On the basis of the above embodiments, this embodiment provides a double-junction Ga 2 o 3device. like Figure 2g As shown, the double junction Ga 2 o 3 The device includes a flexible substrate 1, a first BN film layer 2, a Ga 2 o 3 Substrate 3, P-type Ga 2 o 3 Layer 4, N-type Ga 2 o 3 Layer 5, ZnSe fluorescent layer 6, visible light reflection layer 7, source electrode 8, drain electrode 9 and second BN thin film layer 10, wherein, flexible substrate 1, first BN thin film layer 2, Ga 2 o 3 Substrate 3, P-type Ga 2 o 3 Layer 4, N-type Ga 2 o 3 Layer 5, ZnSe fluorescent layer 6 and visible light reflective layer 7 are arranged sequentially from bottom to top; source electrode 8 and drain electrode 9 are respectively located on the P-type Ga 2 o 3 Layer 4, N-type Ga 2 o 3 layer 5, ZnSe fluorescent layer 6 and the two sides of the laminated structure formed by the visible light reflective layer 7, and the lower surfaces of the source electrode 8 and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com