Electric vehicle IGBT power module overheating and power cycle control method

A technology for power modules and electric vehicles, applied in electric vehicles, electrical devices, vehicle components, etc., can solve undiscovered problems, improve reliability, reduce overheating and power cycle failures, reduce maintenance costs and defect incidence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

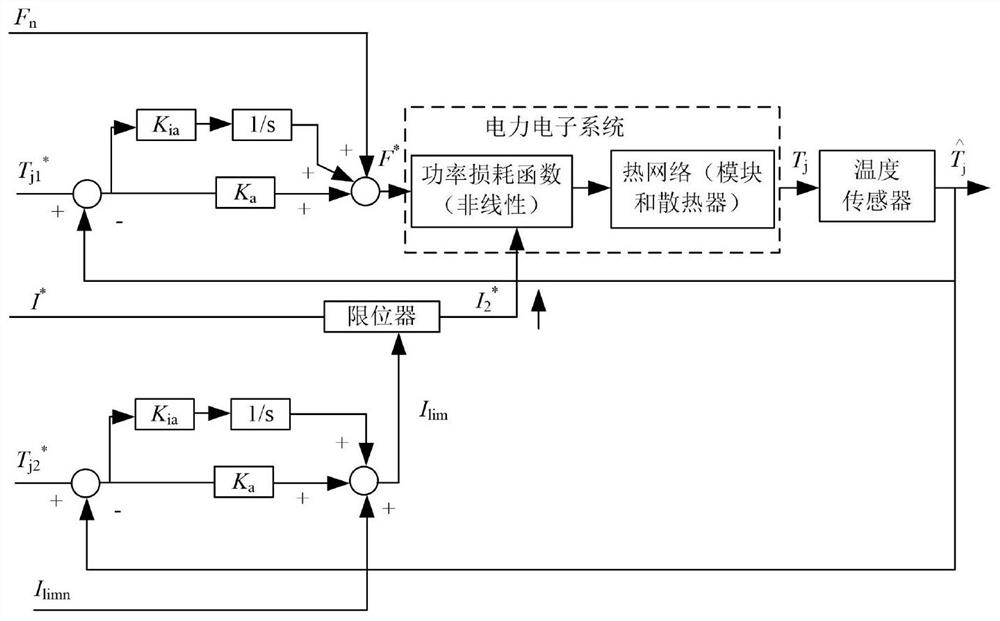

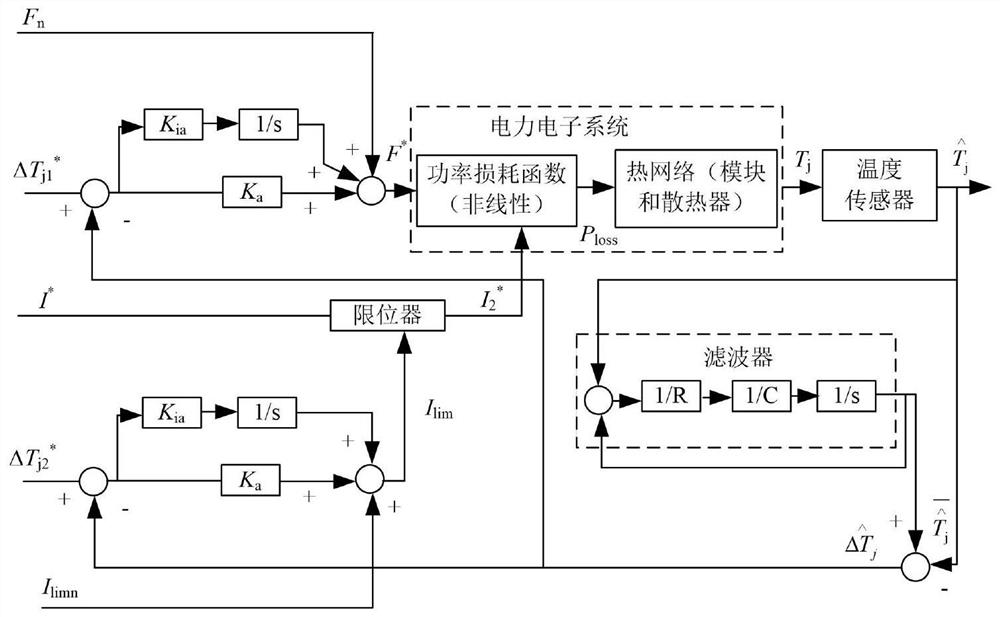

[0029] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

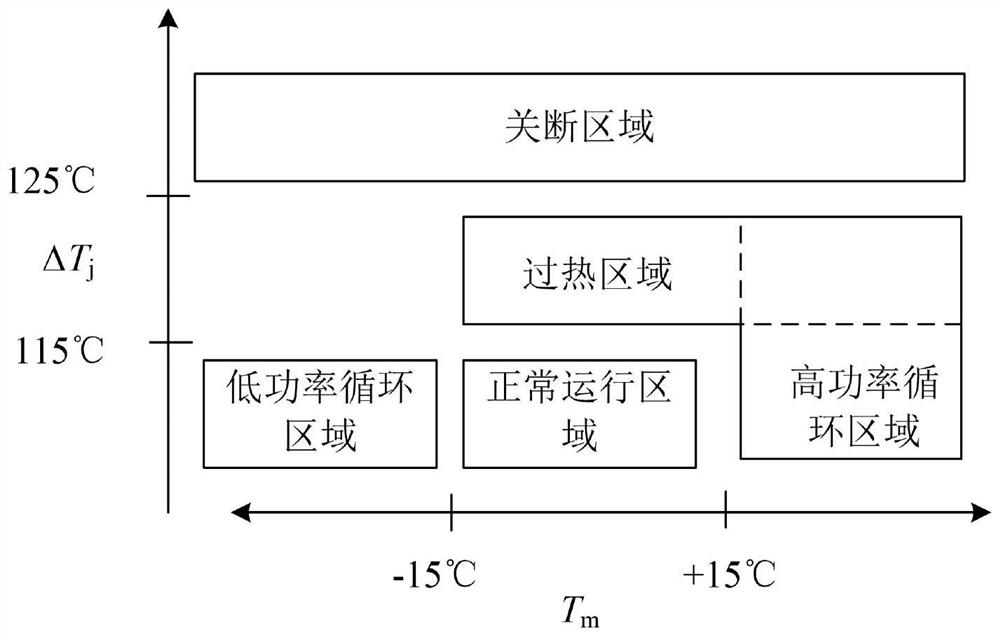

[0030] The present invention considers the average temperature T m and the temperature change ΔT j With the close relationship between overheating and power cycling failures, an area-based control method for regulating these two variables is designed to relieve thermomechanical stress and protect chips from overheating and power cycling failures.

[0031] An electric vehicle IGBT power module overheating and power cycle control method, comprising the following steps:

[0032] Step 1. Analyze the thermal fault parameters of the IGBT power module of the electric vehicle. By adjusting the two variables of switching frequency and output current, control the magnitude of power loss, adjust the temperature inside the IGBT power module, and then control the overheating of the IGBT power module;

[0033] The concrete step method of described step 1 is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com