Rose petal water low-temperature extraction equipment and process

A technology of rose petals and extraction equipment, which is applied in the field of rose petal water low-temperature extraction equipment and technology, which can solve the problems of loss of active ingredients and complicated processing of pure dew, and achieve the effects of improving fluidity, not easy to stick to walls, and easy to drop materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

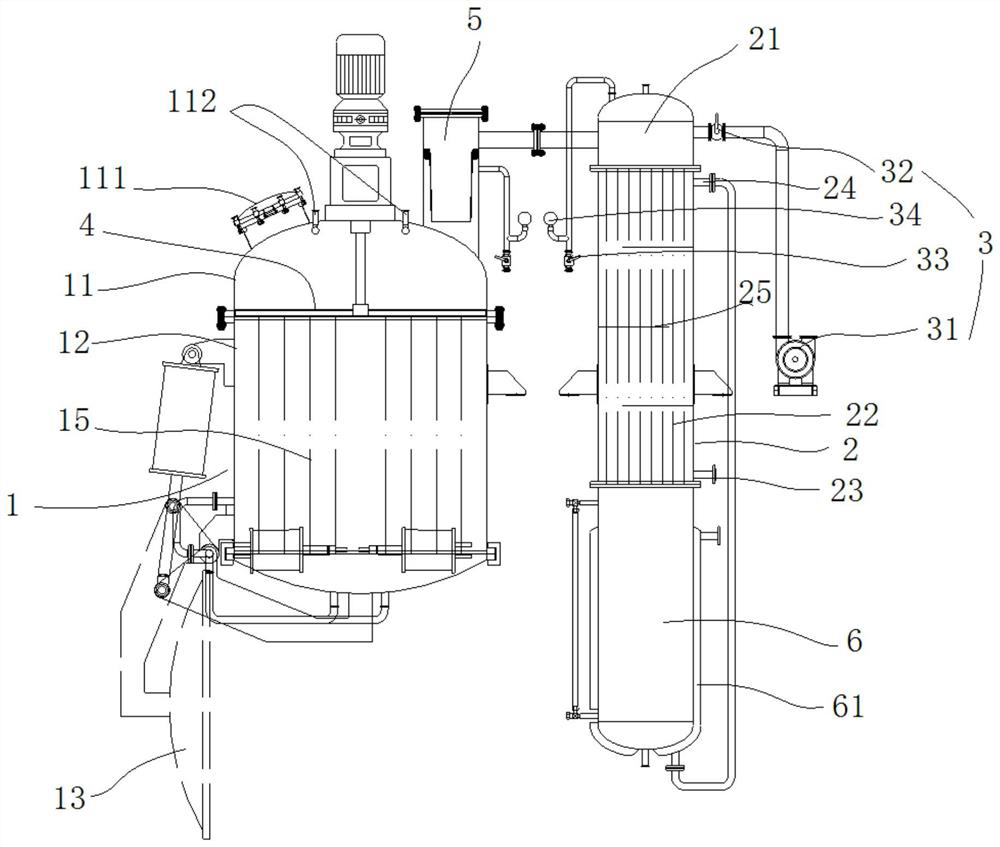

[0070] use figure 1 The structure shown collects rose petal water.

[0071] Step 1, the rose is crushed to 5-30 mesh.

[0072] Close the slag discharge door of the extraction tank, close all valves, only open the vacuum control valve, turn on the vacuum pump, observe the vacuum degree, check the overall sealing of the equipment, and keep the reading of the vacuum gauge unchanged within 30 minutes, that is, confirm that the equipment meets the requirements.

[0073] Step 2, measure the crushed roses and put them into the feeding cavity from the feeding port.

[0074] First open the vent valve, after the vacuum degree is reduced to zero, measure the crushed flowers and put them into the tank from the feeding hole.

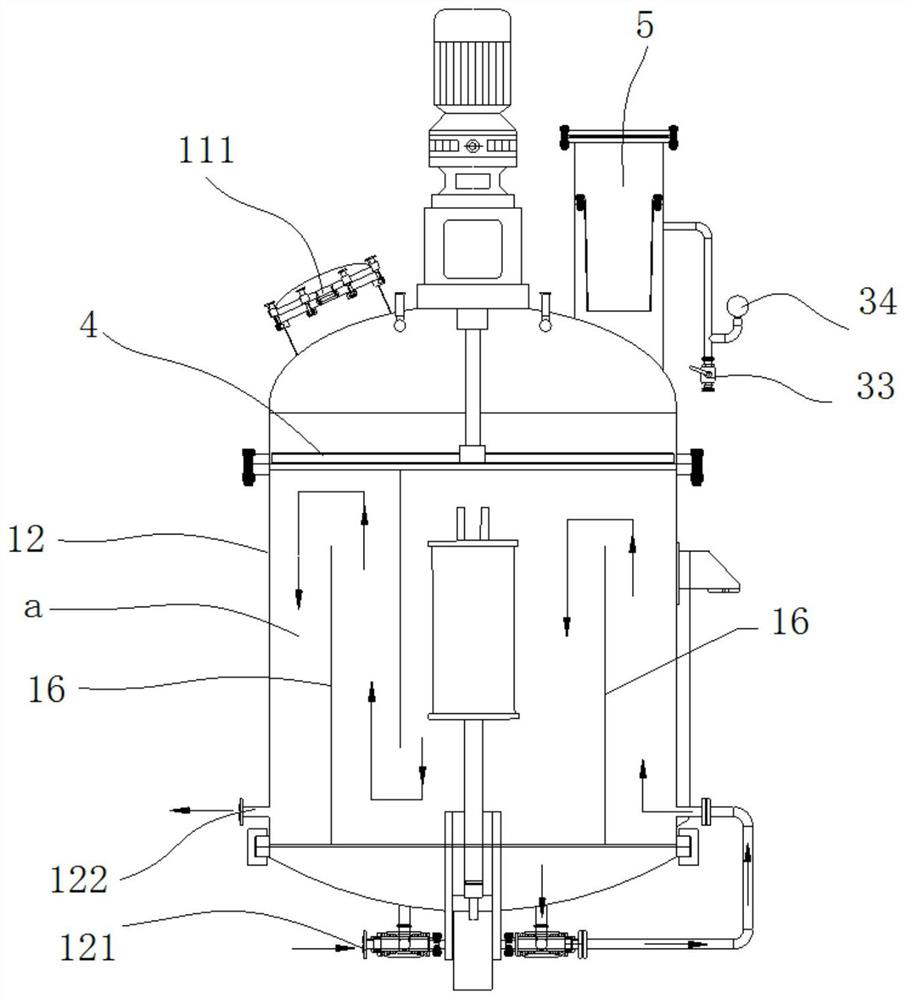

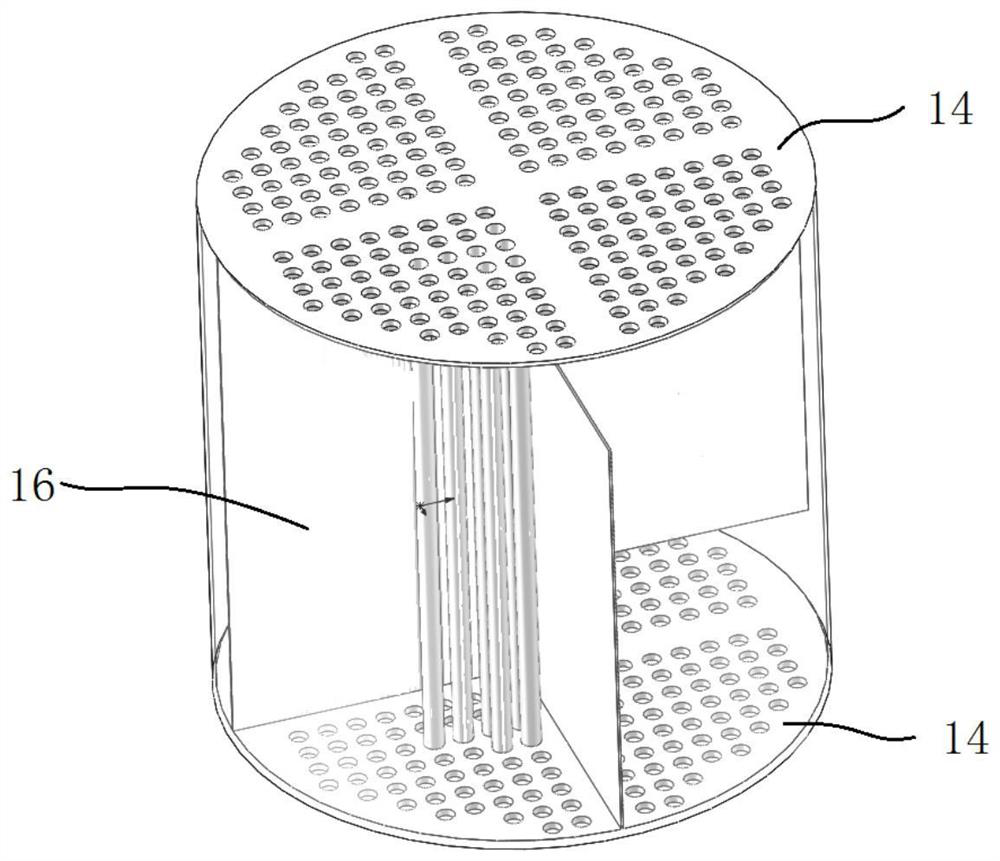

[0075] Step 3, turn on the stirring paddle, and evenly drop the crushed roses into the tubes in the extraction tank;

[0076] Step 4, turn on the vacuum device, pump the vacuum in the extraction tank to above -0.095MPa, close the vacuum control valve, stop the vac...

Embodiment 2

[0089] Step 1, the rose is crushed to 5-30 mesh.

[0090] Close the slag discharge door of the extraction tank, close all valves, only open the vacuum control valve, turn on the vacuum pump, observe the vacuum degree, check the overall sealing of the equipment, and keep the reading of the vacuum gauge unchanged within 30 minutes, that is, confirm that the equipment meets the requirements.

[0091] Step 2, measure the crushed roses and put them into the feeding cavity from the feeding port;

[0092] First open the vent valve, after the vacuum degree is reduced to zero, measure the crushed flowers and put them into the tank from the feeding hole.

[0093] Step 3, turn on the stirring paddle, and evenly drop the crushed roses into the tubes in the extraction tank;

[0094] Step 4, turn on the vacuum device, pump the vacuum in the extraction tank to above -0.095MPa, close the vacuum control valve, stop the vacuum treatment, and maintain the vacuum;

[0095] Step 5, add 15-20 ℃ l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com