Annealing furnace and annealing process for martensitic stainless steel 2Cr13 wire rods

A martensitic stainless steel, 2cr13 technology, applied in the direction of process efficiency improvement, furnace, manufacturing tools, etc., can solve the problems of incomplete heat recovery, high heat loss, large waste of resources, etc., to avoid excessive heat loss, The effect of increasing the heating rate and improving the heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

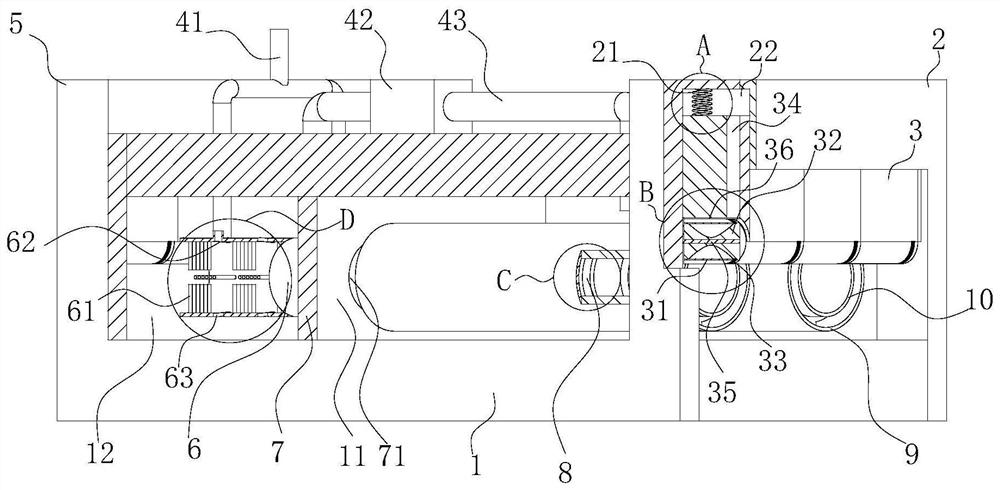

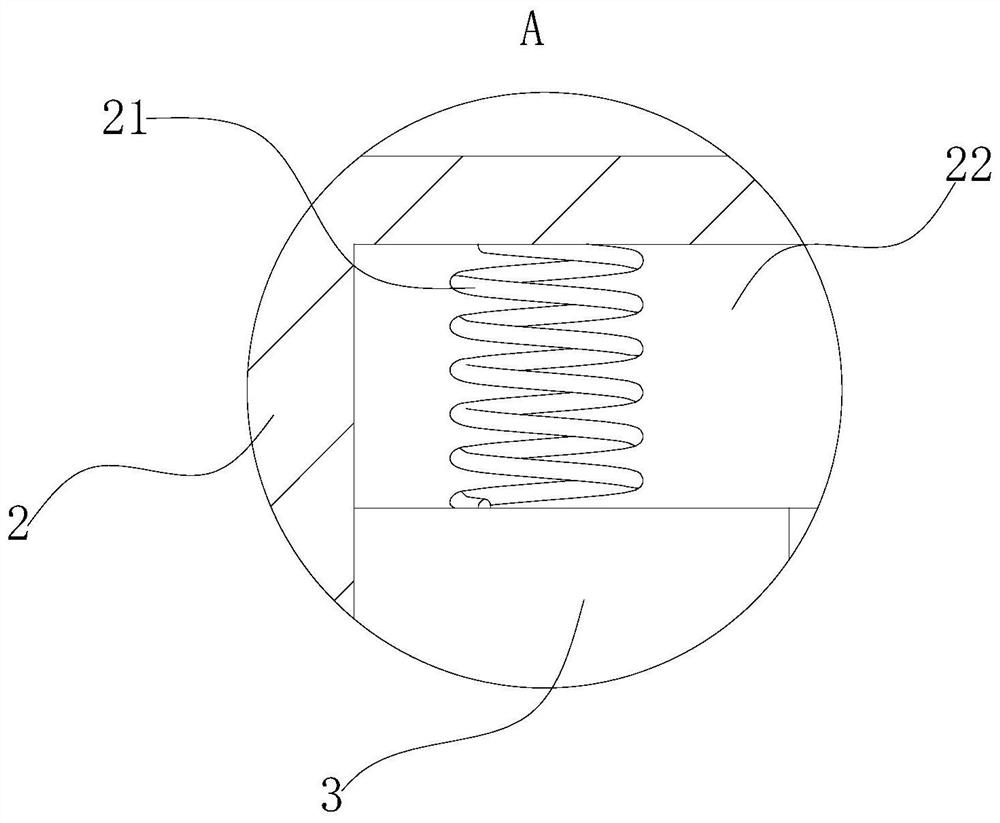

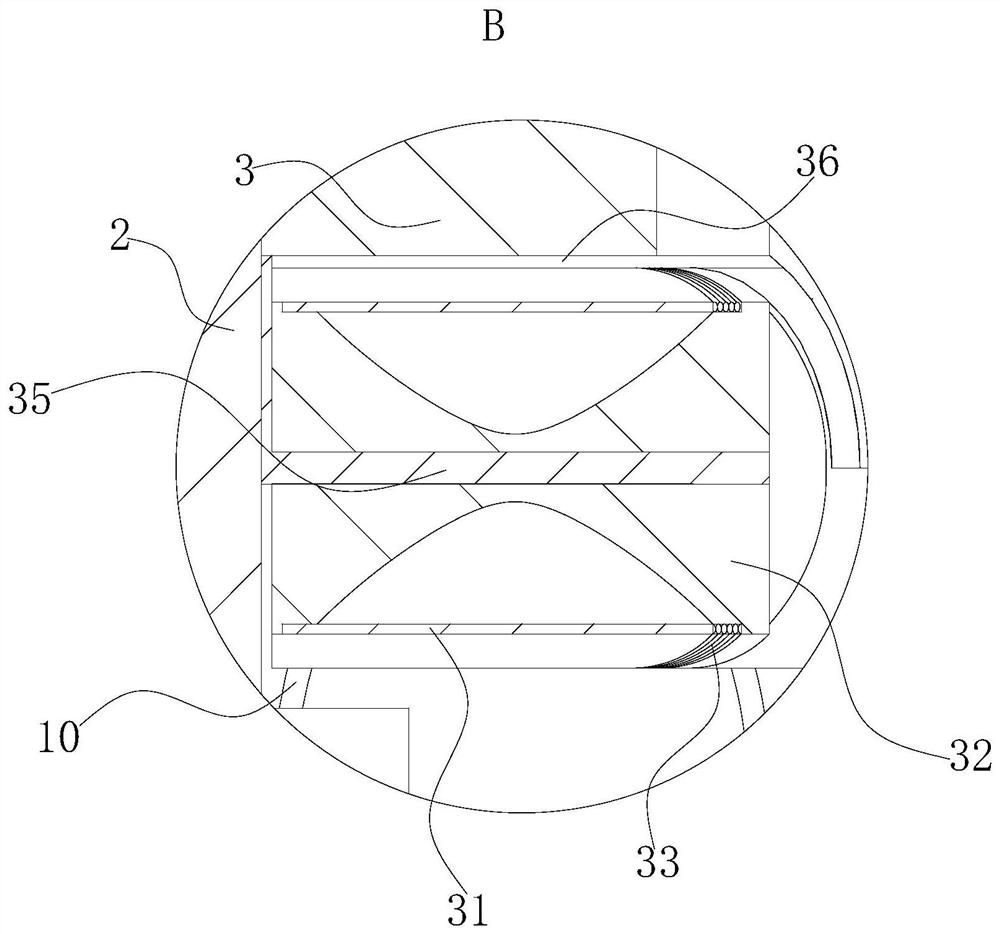

[0039] As an embodiment of the present invention, the lower end of the furnace door baffle plate 3 is provided with a groove 2 36 along the width direction, and a rotating shaft 35 is fixedly installed in the groove 2 36, and a rolling shaft 35 is rotatably installed on the rotating shaft 35. Column 32.

[0040] During work, upwardly open the furnace door baffle 3 in the inner groove 22 of the front furnace door 2, put in the wire rod that needs to be annealed, and then close the furnace door baffle 3 downwards, which is now located at the lower end of the furnace door baffle 3 The roller 32 in the second groove 36 is in direct contact with the wire to be annealed. After the roller 32 is in direct contact with the wire, the roller 32 rotates on the rotating shaft 35, preventing the furnace door baffle 3 from closing downwards. When directly contacting with the wire rod, the surface of the wire rod will be scratched. At the same time, the rotation of the roller 32 can also make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com