Crease-resistant fabric and preparation method thereof

A technology for anti-wrinkle fabrics and cotton fabrics, which is applied in the fields of biochemical fiber processing, textile and papermaking, fiber processing, etc., and can solve the problems of high preparation cost and complex preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

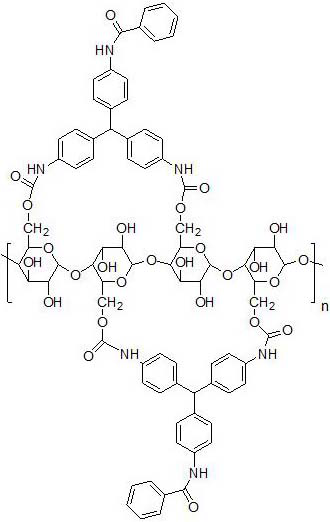

[0030] Preparation Example 1 Modified Cellulose

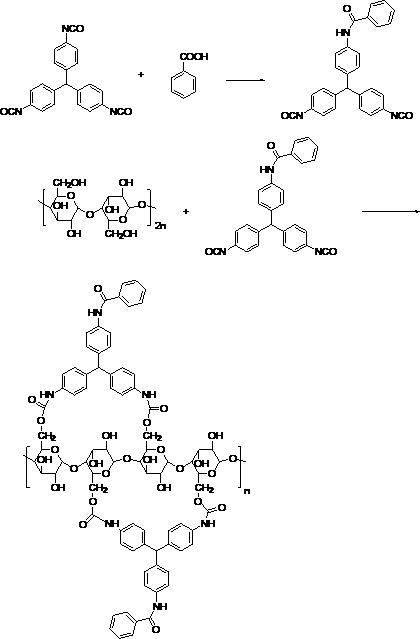

[0031] synthetic route:

[0032]

[0033] The preparation method is as follows:

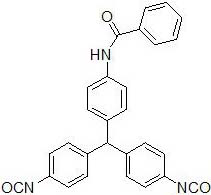

[0034] S1. Preparation of intermediate: Dissolve 1mol 4,4ˊ,4"-triphenylmethane triisocyanate and 1mol benzaldehyde in 200mL diethylbenzene, heat to 135°C, stir and react for 10h, then purify by column chromatography to obtain The intermediate has the structure shown in formula II:

[0035]

[0036] Formula II;

[0037] S2. Preparation of modified cellulose:

[0038] 10g of cellulose was pulverized, sieved, immersed in 100mL of 10wt% NaOH solution for 20min, filtered and washed to obtain pretreated cellulose;

[0039] Dissolve 3 g of pretreated cellulose and 5 g of intermediate in 50 mL of toluene, add 0.06 g of potassium carbonate, stir for 3 h, filter, wash the solid with ethanol, and dry to obtain modified cellulose.

[0040] In the infrared measurement spectrum, 3420cm-1 and 2925cm-1 are the absorption peaks of -OH and C-H; 3100cm-1 ...

preparation example 2

[0041] Preparation Example 2 Modified Cellulose

[0042] The preparation method is as follows:

[0043] S1. Preparation of intermediate: Dissolve 1mol 4,4ˊ,4"-triphenylmethane triisocyanate and 1mol benzaldehyde in 200mL ethylbenzene, heat to 150°C, stir and react for 15h, then purify by column chromatography to obtain intermediate Body, has the structure shown in formula II;

[0044] S2. Preparation of modified cellulose:

[0045] 10g of cellulose was pulverized, sieved, immersed in 100mL of 15wt% NaOH solution for 30min, filtered and washed to obtain pretreated cellulose;

[0046] Dissolve 3 g of pretreated cellulose and 6 g of intermediate in 50 mL of toluene, add 0.15 g of potassium carbonate, stir for 5 h, filter, wash the solid with ethanol, and dry to obtain modified cellulose.

preparation example 3

[0047] Preparation example 3 modified cellulose

[0048] The preparation method is as follows:

[0049]S1. Preparation of intermediate: Dissolve 1mol 4,4ˊ,4"-triphenylmethane triisocyanate and 1mol benzaldehyde in 200mL xylene, heat to 140°C, stir and react for 12h, then purify by column chromatography to obtain intermediate Body, has the structure shown in formula II;

[0050] S2. Preparation of modified cellulose:

[0051] 10g of cellulose was pulverized, sieved, immersed in 100mL of 12wt% NaOH solution for 25min, filtered and washed to obtain pretreated cellulose;

[0052] Dissolve 3 g of pretreated cellulose and 5.5 g of intermediate in 50 mL of toluene, add 0.1 g of potassium carbonate, stir for 4 h, filter, wash the solid with ethanol, and dry to obtain modified cellulose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com