Gold connecting line of semiconductor device and production method thereof

A production method and technology for connecting wires, applied in conductors, connections, insulated conductors, etc., can solve problems such as inability to semiconductor devices, affect equipment operation, copper core damage, etc. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

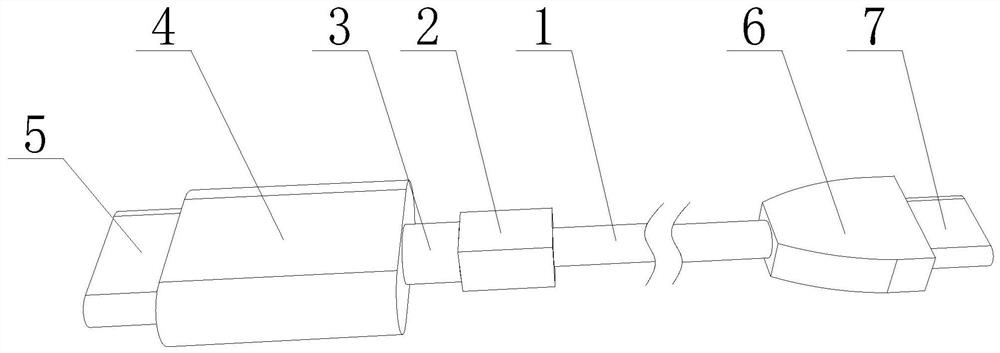

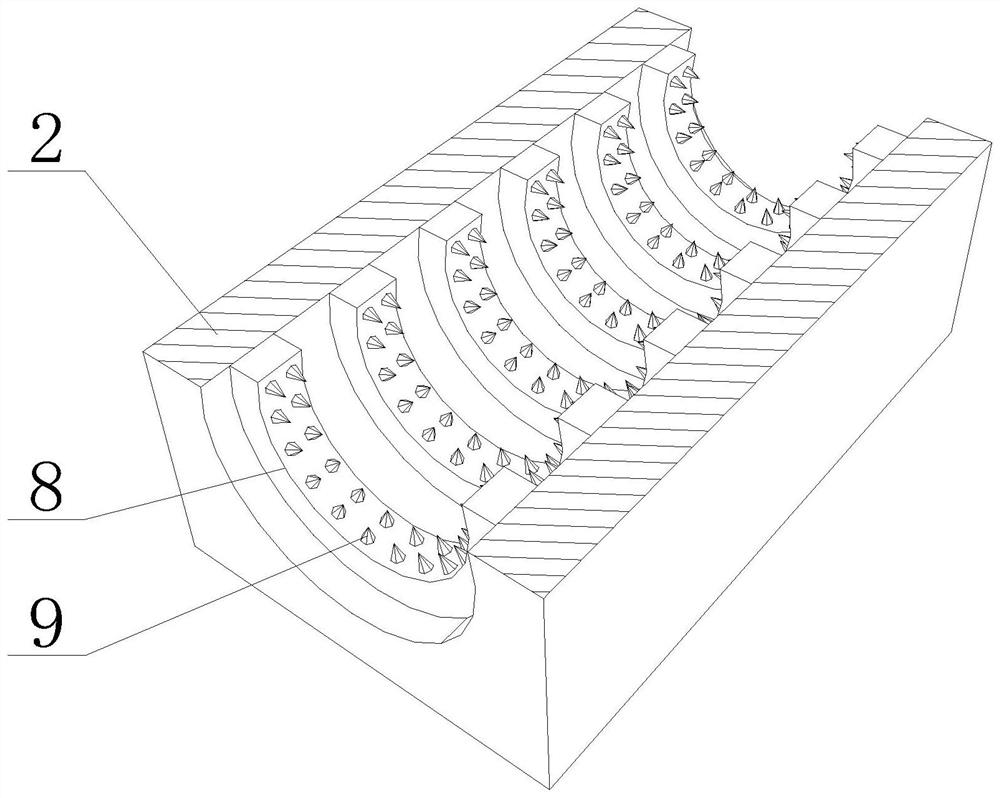

[0043] First aspect, such as figure 1 - Figure 4 As shown, the present invention provides a gold connecting wire of a semiconductor device, comprising a connecting wire main body 1, a fixed connection end 3, a semiconductor connector 4 and a semiconductor end 5, and the left side of the connecting wire main body 1 is fixedly connected with Fixed connection end 3, semiconductor connector 4 is fixedly installed on the left side of fixed connection end 3, semiconductor terminal 5 is fixedly installed on the left side of semiconductor connector 4, and the surface of connecting line main body 1 is provided with connection Wire protection end 2, the connecting wire protection end 2 is used to protect the end of the connecting wire body 1 to prevent breakage, the right side of the connecting wire body 1 is provided with an electromagnetic reducer 6, and the electromagnetic reducer 6 is used to protect the connecting wire The current output by the main body 1 is electromagnetically ...

Embodiment 2

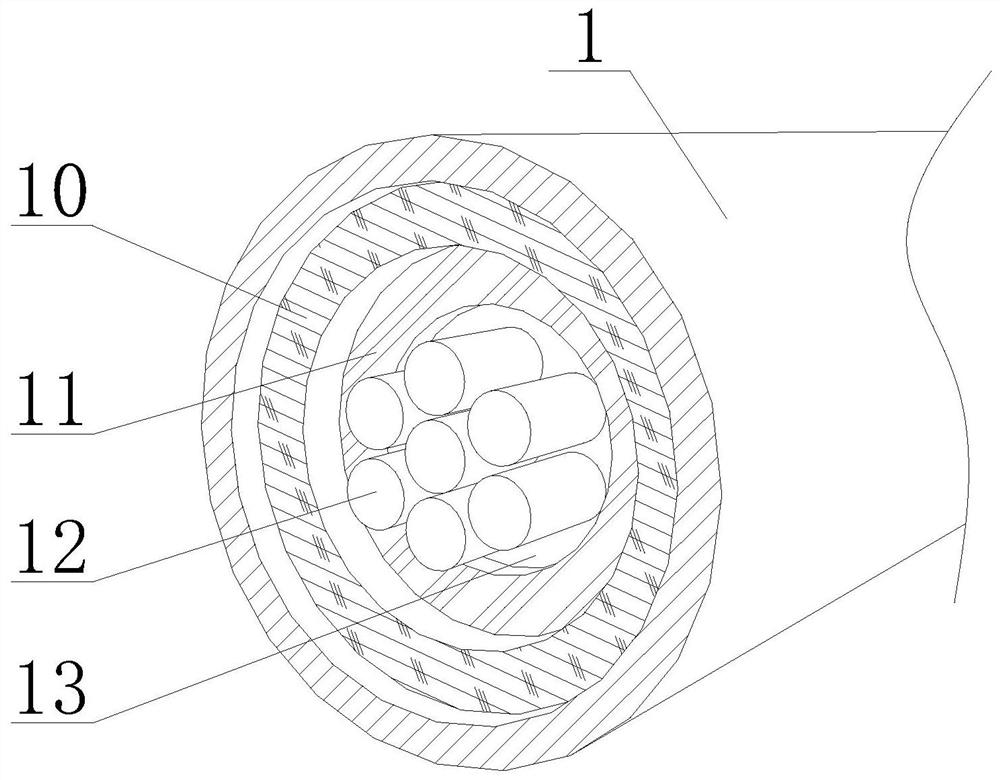

[0045] Such as Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a copper wire protective layer 13 is provided inside the connecting wire main body 1 and on the inner side of the anti-electromagnetic layer 11, and the surface of the copper wire protective layer 13 is fixedly installed On the inner wall of the anti-electromagnetic layer 11, and the left and right ends of the copper wire protective layer 13 are fixedly installed on the inner wall of the connecting wire main body 1, the inside of the copper wire protective layer 13 is provided with copper wires 12, and the copper wire protective layer 13 can The copper wire 12 has a protective effect to prevent the copper wire 12 from being damaged during use. The surface of the copper wire 12 is fixedly installed on the inner wall of the copper wire protective layer 13, and the left and right ends of the copper wire 12 are fixedly installed on the connecting wire body 1. On ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com