Laser cutting device

A laser cutting and laser head technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of affecting the second surface processing, difficult to remove, affecting installation, etc., to improve cutting efficiency and improve cutting quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

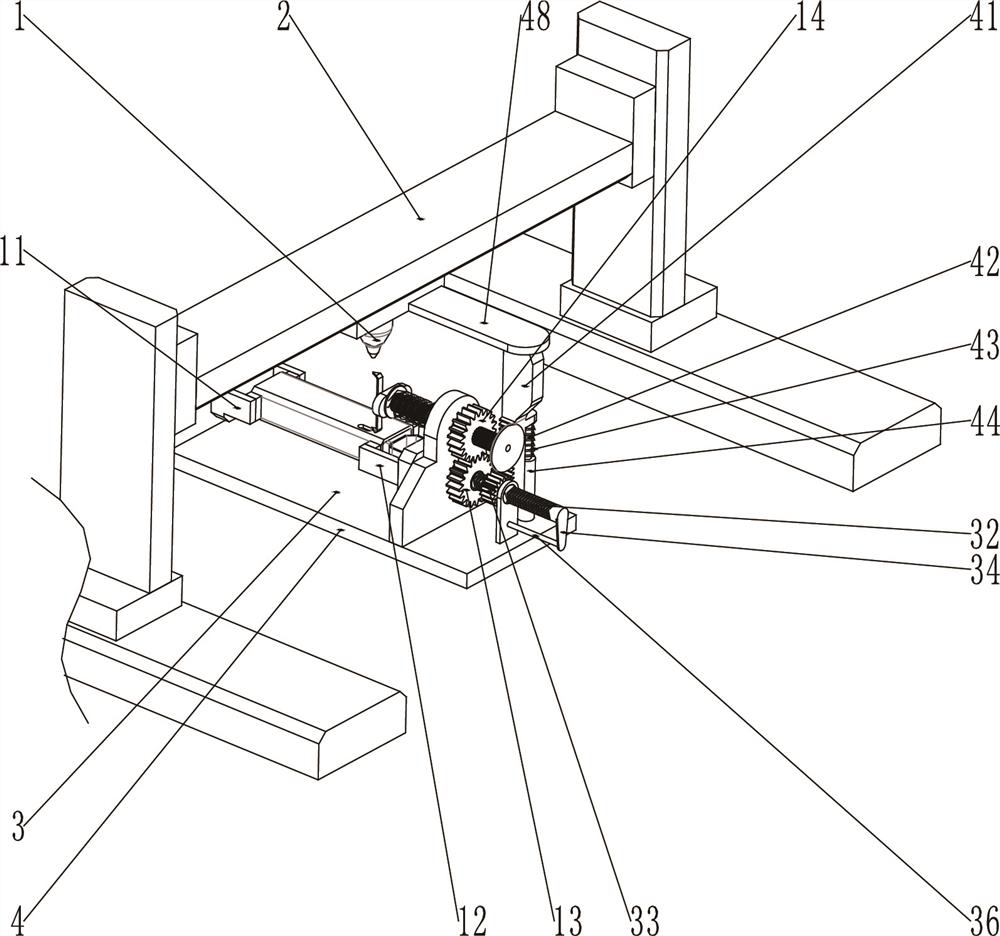

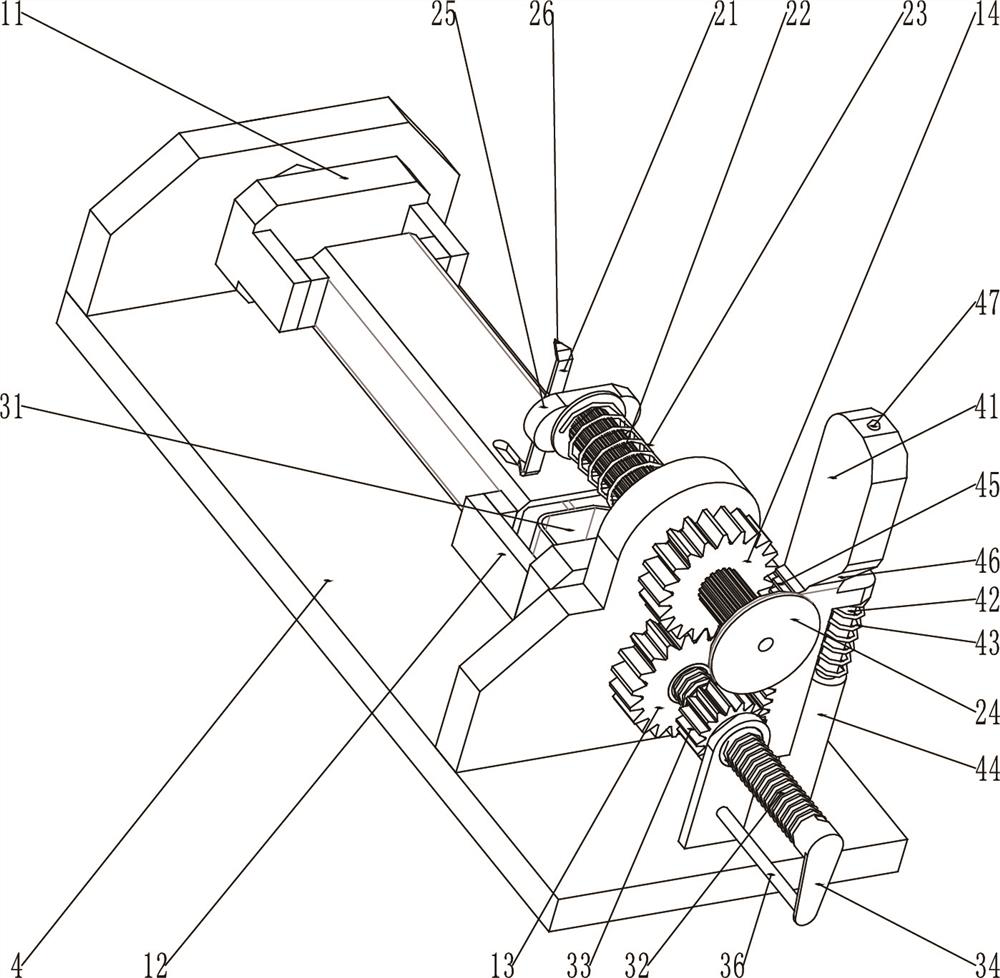

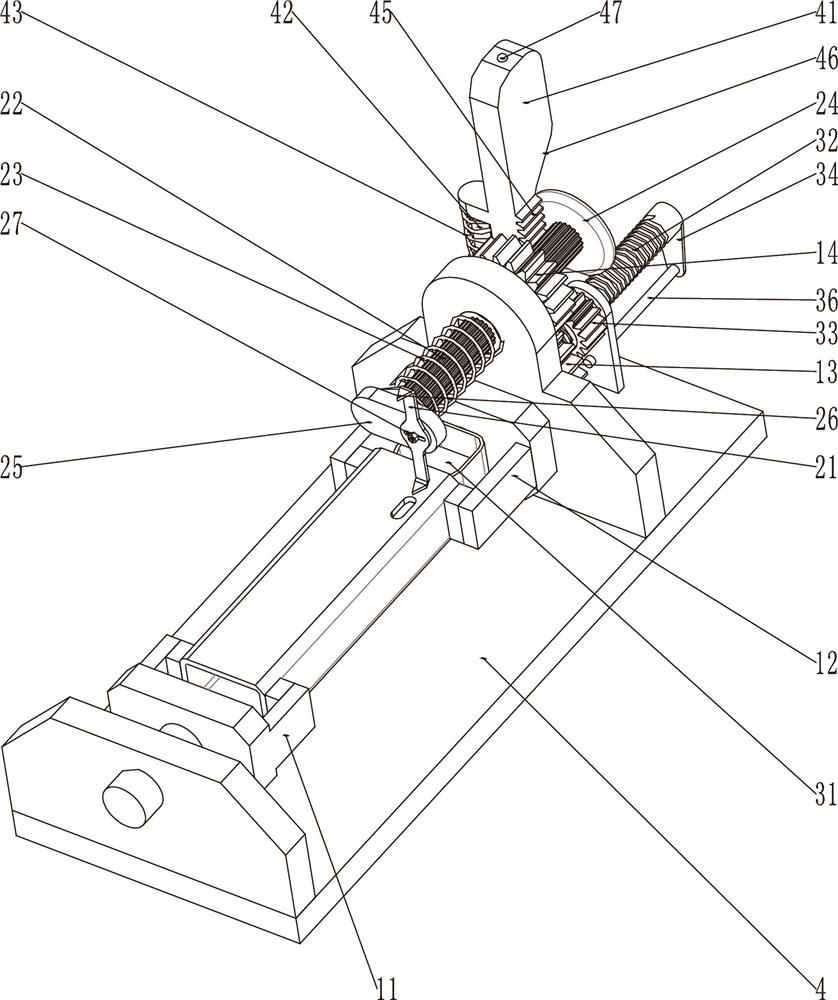

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 8 , laser cutting device, including laser head 1, mobile module 2 and fixture 3, described laser head 1 is located on mobile module 2, and described mobile module 2 is the moving device of existing laser head 2, all adopts PLC Control, this is the prior art, the clamp 3 is arranged below the laser head 2 and is used to position the pipe.

[0025] Described fixture 3 comprises frame 4, and described frame 4 is provided with driving collet 11 and driven collet 12, and the clamping mechanism between described driving collet 11, driven collet 12 and pipe fitting is existing. Some clamping chucks are not described in detail here. The active chuck 11 is provided with an active shaft, and the rotation of the active shaft is arranged on the frame 4. The active shaft is connected with a drive motor for driving The active shaft ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com