Novel underground instrument antenna winding method

A technology of downhole instrument and winding method, applied in the field of downhole instrument antenna, can solve the problems of loose cover, large amount of work and high cost, and achieve the effects of reducing the amount of work, good self-lubrication and high firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

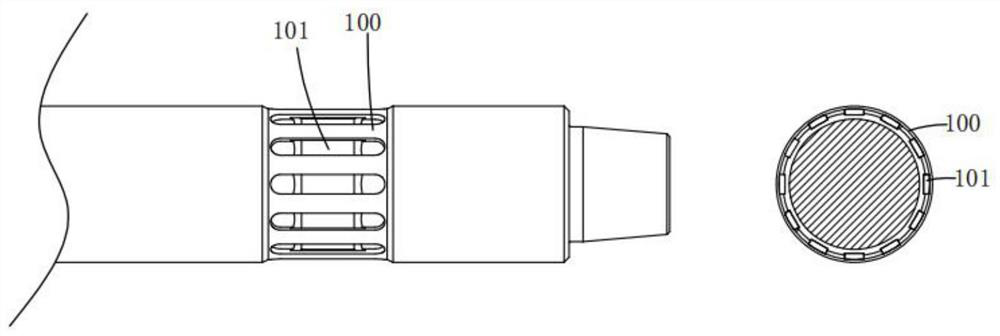

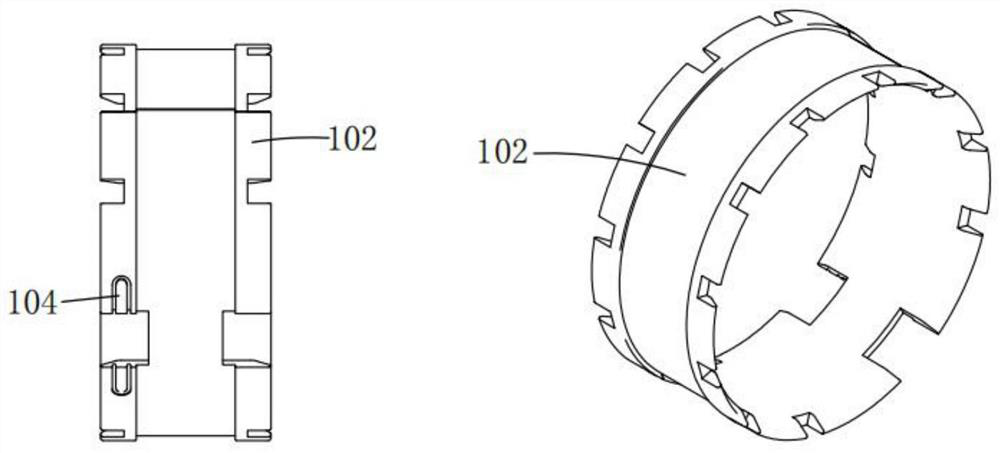

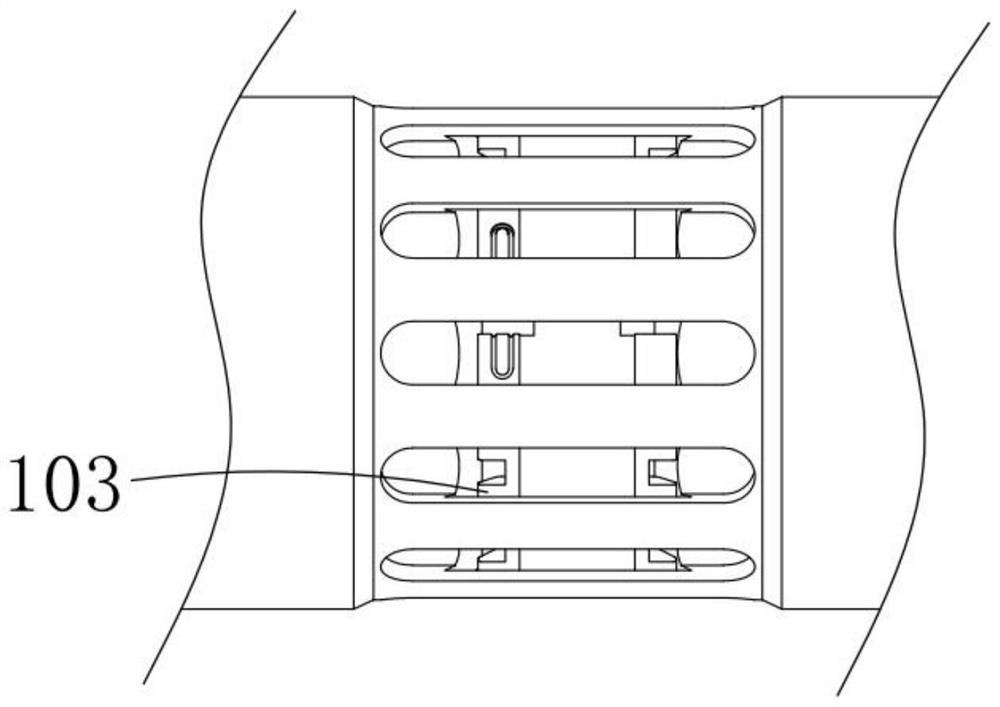

[0034] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 ,in, figure 1 It is a schematic diagram of the antenna slot in the present invention; figure 2 It is a schematic diagram of the skeleton in the present invention; image 3 It is a schematic diagram of the toggle gap in the present invention; Figure 4 It is a structural schematic diagram of the antenna cover drilling device in the present invention; Figure 5 It is a structural schematic diagram of the clamping mechanism in the present invention; Figure 6 It is a structural schematic diagram of the mobile assembly in the present invention. The new downhole instrument antenna winding method includes the following steps: S1, material preparation:

[0035] (1). Antenna housing main body 100, antenna coil, frame 102 and antenna fixing joint 104;

[0036] S2, process:

[0037] (1) Groove drilling: the antenna cover main body 100 is drilled through the antenna cover drilling de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com