Lead-free piezoelectric ceramic material with high transduction coefficient and preparation method thereof

A lead-free piezoelectric and ceramic material technology, applied in the field of lead-free piezoelectric ceramic materials, can solve the problems of power demand gap and low power density of electronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

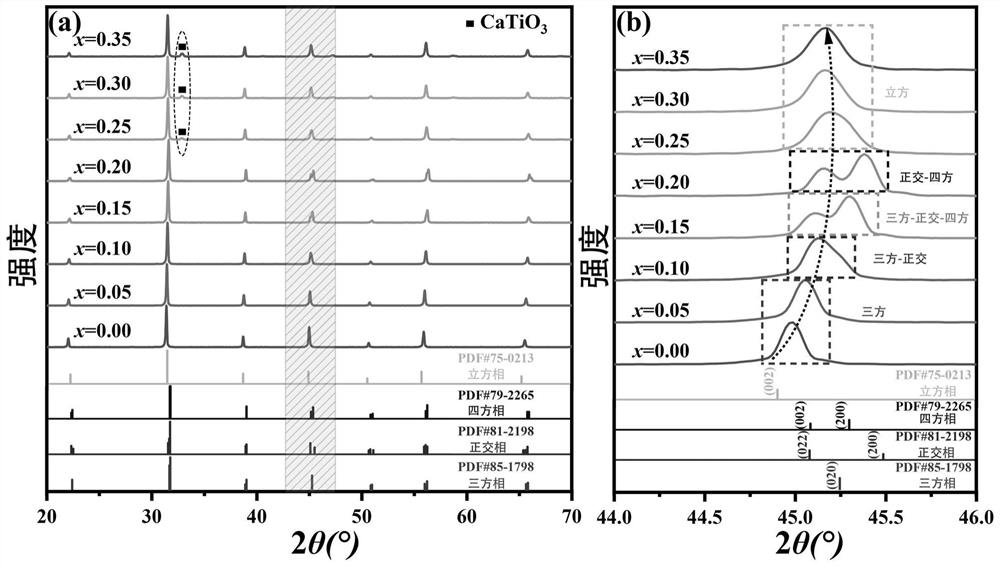

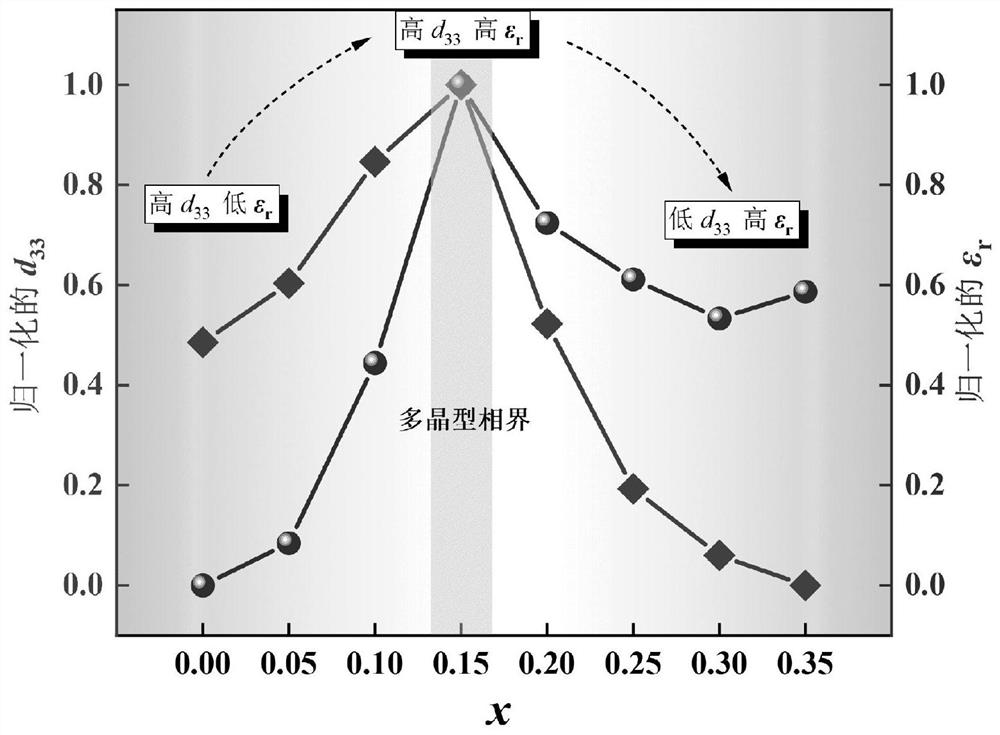

Method used

Image

Examples

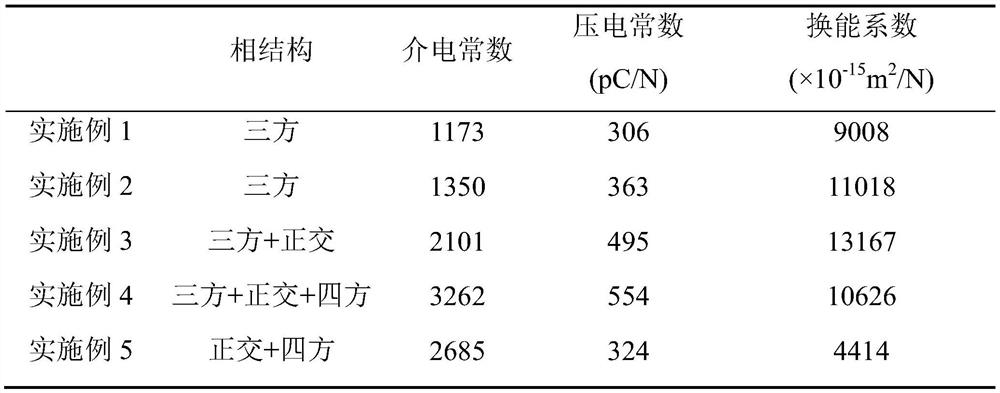

Embodiment 1

[0018] Embodiment 1 (comparative example):

[0019] According to the chemical formula 0.90BaTiO 3 -0.10BaZrO 3 Weigh ZrO 2 、BaCO 3 、TiO 2 , milled in a horizontal ball mill for 24 hours with anhydrous ethanol as the medium, and then dried at 100°C. The dried mixture was calcined at 1200 °C for 4 hours, ball milled for 24 hours and dried to obtain 0.90 BaTiO 3 -0.10BaZrO 3 Submicron powder, add 5wt.% polyvinyl alcohol binder for granulation, directly press molding under the pressure of 100MPa, then keep it at 560°C for 9 hours to remove the binder, and finally solidify at 1500°C Phase sintering and heat preservation for 3 hours to obtain dense ceramics.

Embodiment 2

[0021] According to the chemical formula 0.85BaTiO 3 -0.05CaTiO 3 -0.10BaZrO 3 Weighing Weighing ZrO 2 、BaCO 3 , CaCO 3 、TiO 2 , other with embodiment 1.

Embodiment 3

[0023] According to the chemical formula 0.80BaTiO 3 -0.10CaTiO 3 -0.10BaZrO 3 Weighing Weighing ZrO 2 、BaCO 3 , CaCO 3 、TiO 2 , other with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com