Liquid crystal orientation agent and application thereof

A technology of liquid crystal aligning agent and liquid crystal aligning film, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., and can solve the problems of accumulating images, retention, low contrast and low charge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

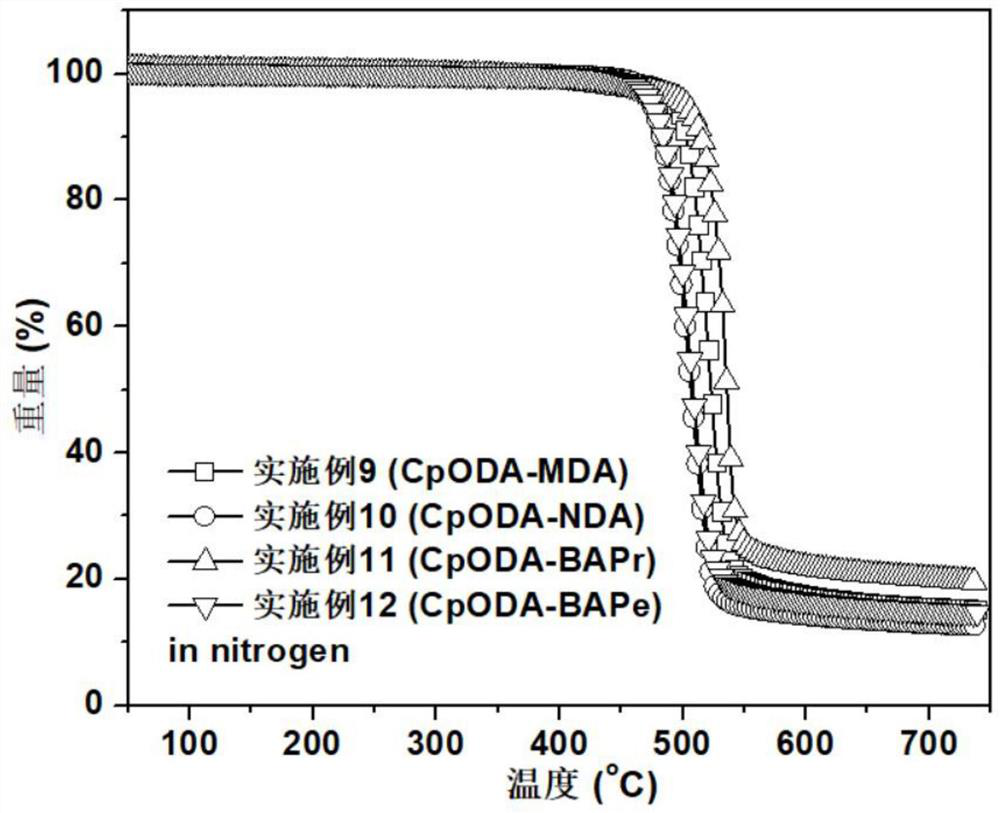

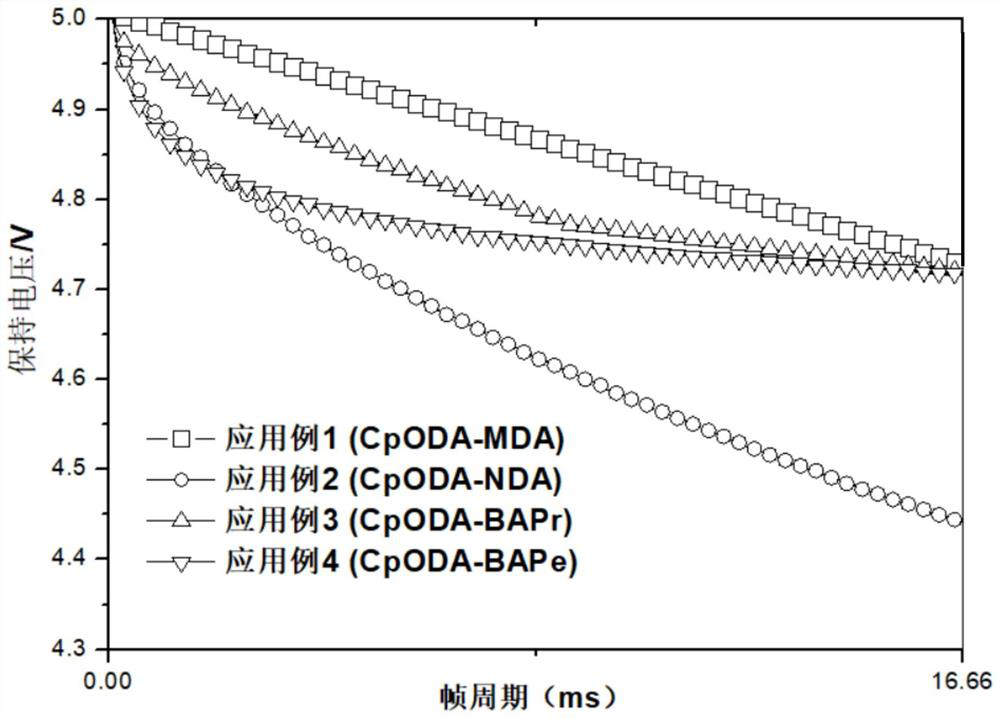

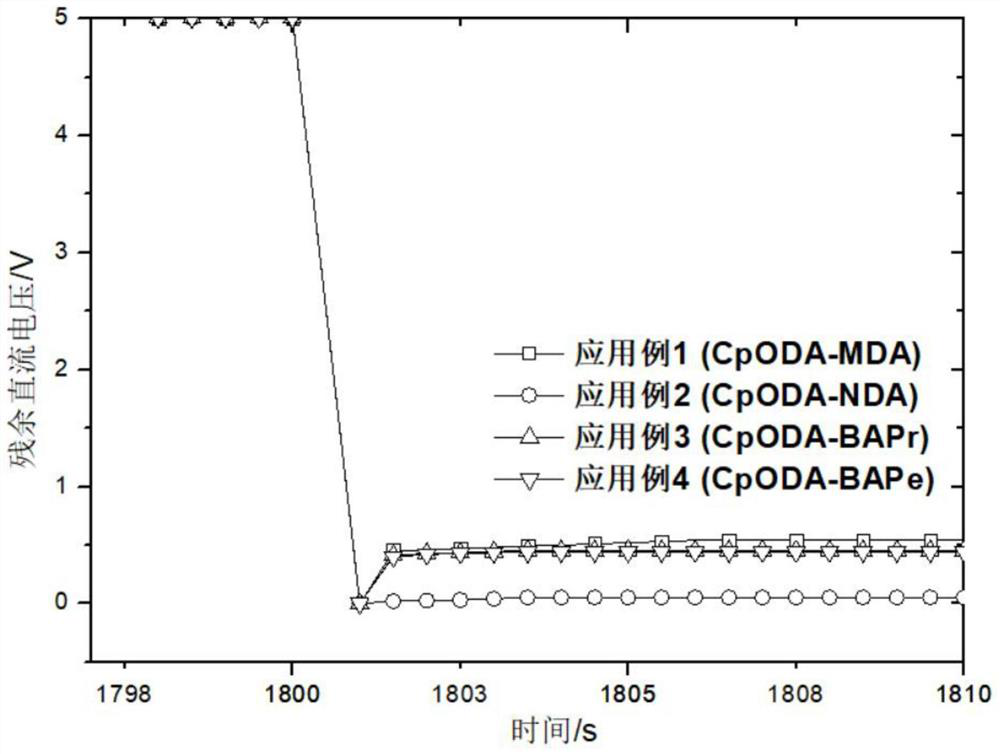

Examples

Embodiment 1

[0070] A kind of polyimide, its preparation method comprises the following steps:

[0071] S1, put 23.78g of DDM (monomer 1 containing diamine structure) into a three-necked flask with nitrogen protection, add 250g of NMP, mix well, and then add 48.05g of CpODA (monomer 2 containing dianhydride structure ), reacted for 24 hours at normal temperature;

[0072] S2, heating the reaction liquid obtained in S1 to raise the temperature to 60° C., then adding 49.38 g of pyridine and 63.75 g of acetic anhydride to the reaction liquid, and reacting for 24 hours;

[0073] S3, adding the reaction solution obtained in S2 into ethanol for spinning to obtain a white filamentous solid, and washing the obtained white filamentous solid with ethanol to obtain a crude polyimide product.

[0074] S4: Put the crude polyimide product obtained in S3 into 250 g of NMP, fully dissolve it, then add it into ethanol for reprecipitation, filter and retain the solid, and obtain a refined polyimide product...

Embodiment 2

[0076] A kind of polyimide, its preparation method comprises the following steps:

[0077] S1, put 24.90g of NDA (monomer 1 containing diamine structure) into a three-necked flask with nitrogen protection, add 250g of NMP, mix well, and then add 48.05g of CpODA (monomer 2 containing dianhydride structure) ), reacted for 24 hours at normal temperature;

[0078] S2, heating the reaction liquid obtained in S1 to raise the temperature to 60° C., then adding 49.38 g of pyridine and 63.75 g of acetic anhydride to the reaction liquid, and reacting for 24 hours;

[0079] S3, adding the reaction solution obtained in S2 into ethanol for spinning to obtain a white filamentous solid, and washing the obtained white filamentous solid with ethanol to obtain a crude polyimide product.

[0080] S4: Put the crude polyimide product obtained in S3 into 250 g of NMP, fully dissolve it, then add it into ethanol for reprecipitation, filter and retain the solid, and obtain a refined polyimide produc...

Embodiment 3

[0082] A kind of polyimide, its preparation method comprises the following steps:

[0083] S1, put 32.29g of BAPr (monomer 1 containing diamine structure) into a three-necked flask with nitrogen protection, add 250g of NMP, mix well, and then add 48.05g of CpODA (monomer 2 containing dianhydride structure) ), reacted for 24 hours at normal temperature;

[0084] S2, heating the reaction liquid obtained in S1 to raise the temperature to 60° C., then adding 49.38 g of pyridine and 63.75 g of acetic anhydride to the reaction liquid, and reacting for 24 hours;

[0085] S3, adding the reaction solution obtained in S2 into ethanol for spinning to obtain a white filamentous solid, and washing the obtained white filamentous solid with ethanol to obtain a crude polyimide product.

[0086] S4: Put the crude polyimide product obtained in S3 into 250 g of NMP, fully dissolve it, then add it into ethanol for reprecipitation, filter and retain the solid, and obtain a refined polyimide produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com