Heat-resistant soft semi-conductive shielding PP cable material and preparation method thereof

A semi-conductive and conductive filler technology, used in the field of PP cable shielding materials, can solve problems such as poor structural stability and shortened service life, and achieve the effects of reducing hardening and brittleness, increasing flexibility and reducing weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention provides a heat-resistant soft semi-conductive shielding PP cable material, which comprises: 68.70% of compounded homopolymer, 4.60% of Clariant OP wax, 0.24% of antioxidant, 26.46% of Conductive filler; the mixing and compounding homopolymer includes: 45.80% PP resin, 32.40% PP-R material, and 21.80% epoxy resin in terms of weight percentage; the conductive filler includes: 14.80% in weight percentage % three-dimensional graphene porous film, 14.80% acetylene carbon black, 14.80% expanded graphite, 13.50% polyimide fiber, 13.50% nano cellulose, 13.50% nano zirconium diboride, 15.10% nano calcium carbonate;

[0027]Described antioxidant is antioxidant 1010, antioxidant 168, antioxidant AO-60, antioxidant HP-10, antioxidant 1024, antioxidant 1035, antioxidant 1076, antioxidant 300 and Compounded with one or more kinds of antioxidant DSTP;

[0028] The present invention also provides a method for preparing a heat-resistant soft semi-conductive shielded PP ...

Embodiment 2

[0037] Different from Example 1, it includes: 80.90% mixing and compounding homopolymer, 7.80% Clariant OP wax, 0.46% antioxidant, 10.84% conductive filler according to weight percentage; According to the calculation of weight percentage, the compound homopolymer includes: 48.60% PP resin, 34.60% of PP-R material, and 16.80% epoxy resin; the described conductive filler includes 15.60% of three-dimensional graphene porous film, 15.60% of weight percentage. % acetylene carbon black, 15.60% expanded graphite, 14.70% polyimide fiber, 14.70% nano cellulose, 14.70% nano zirconium diboride, 9.10% nano calcium carbonate.

Embodiment 3

[0039] All different from Examples 1-2, it includes: 74.80% mixing and compounding homopolymer, 6.20% Clariant OP wax, 0.35% antioxidant, 18.65% conductive filler according to weight percentage; The mixing and compounding homopolymer includes: 47.20% PP resin, 33.50% PP-R material, and 19.30% epoxy resin by weight percentage; the conductive filler includes: 15.20% three-dimensional graphene by weight percentage Porous film, 15.20% acetylene carbon black, 15.20% expanded graphite, 14.10% polyimide fiber, 14.10% nano cellulose, 14.10% nano zirconium diboride, 12.10% nano calcium carbonate.

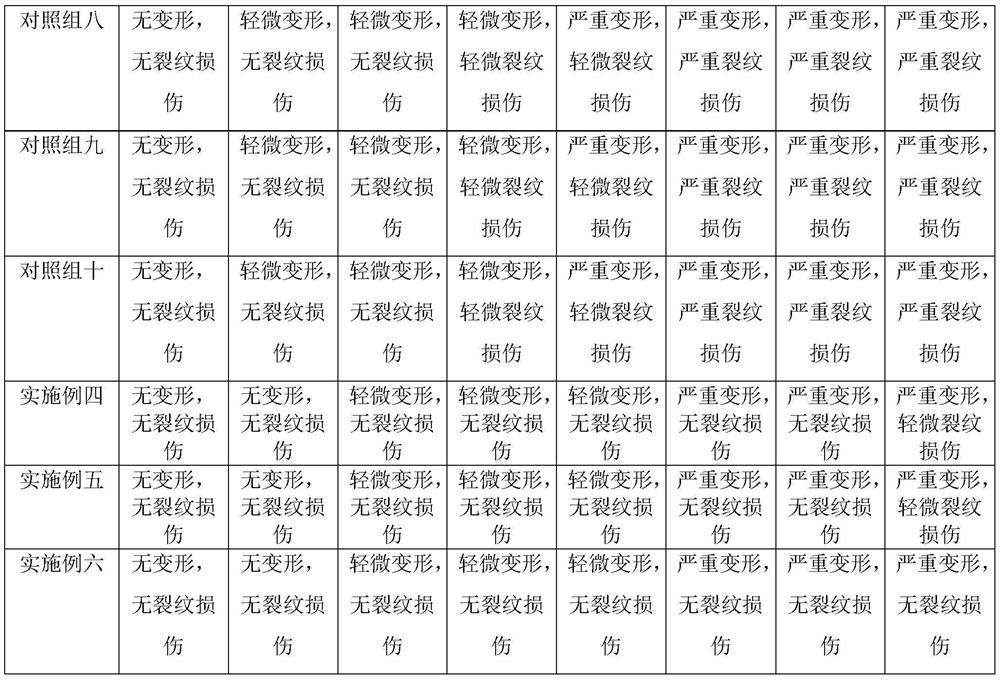

[0040] Get the semiconductive shielded PP cable material that above-mentioned embodiment 1-3 makes and the semiconductive shielded PP cable material of control group one, the semiconductive shielded PP cable material of control group two, the semiconductive shielded PP cable of control group three Materials, semi-conductive shielded PP cable material of control group four, semi-conductive sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com