Method for producing PHA by culturing halophilic bacteria with low-salt culture medium

A technology for halophilic bacteria and culture medium, applied in the field of culturing halophilic bacteria with low-salt culture medium to produce PHA, can solve the problems of increasing the production cost of PHA and the high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Example 1: Low-salt medium culture produces halophilic bacteria cells containing PHB, and extracts and purifies PHA from the fermentation broth

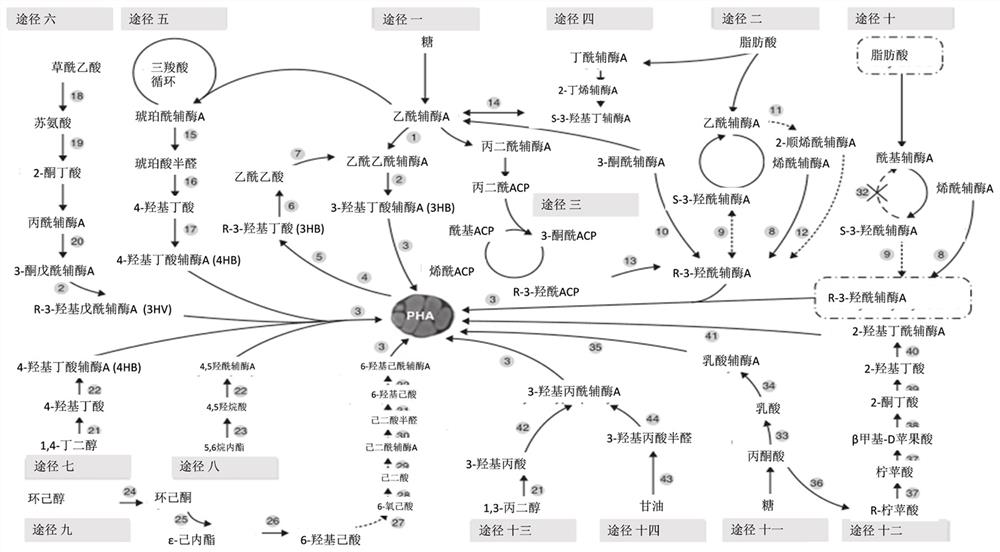

[0088] In the present invention, by adding glucose as a carbon source in halophilic bacteria (see Table 1), the PHA synthase ( phaC ) under the action of its own metabolism to produce 3HB-CoA and polymerize into PHB.

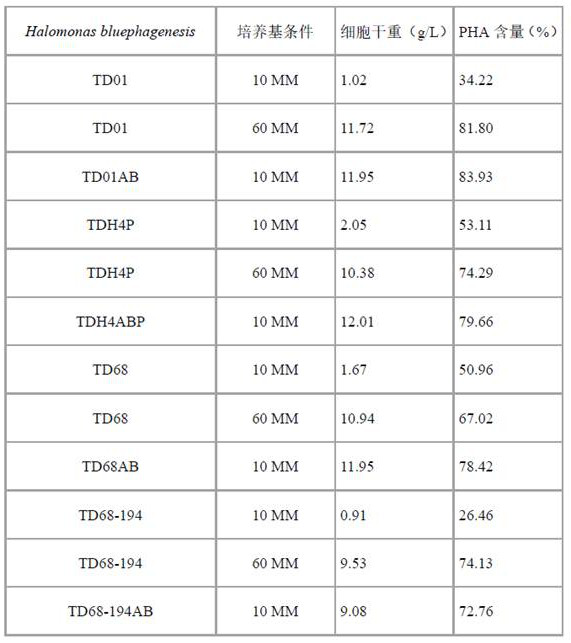

[0089] Cultivate TD01, TD01AB, TDH4P, TDH4ABP, TD68, TD68AB, TD68-194 and TD68-194AB in 10LB respectively, and TD01, TDH4P, TD68 and TD68-194 in 60LB medium at 37°C and 200 rpm for 12 hours After that, they were inoculated into 50mL 10MMG and 60MMG medium at 1%, respectively, and 30g / L glucose was added as a carbon source at the same time, and cultured for 48 hours. After 48 hours, the bacteria were collected, and the dry cell weight and PHA content were detected. Three parallel samples were set for each experiment, and the results were averaged. The results are shown in Table 1 below:

[0090] Table 1 Vario...

Embodiment 2

[0093] Example 2: Cultivate and produce halophilic bacteria cells containing P3HB4HB in low-salt medium, and extract and purify PHA from the fermentation broth

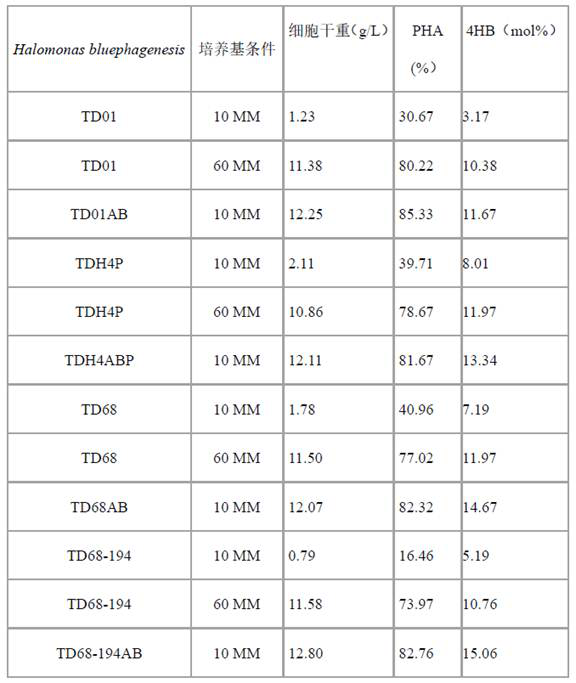

[0094] The invention passes through the Halomonas bluephagenesis 4-Hydroxybutyryl-CoA transferase ( orf Z ) to synthesize 4HB-CoA, and in the cell's own PHA synthase ( phaC ) under the action of 3HB-CoA produced by its own metabolism to form P(3HB-co-4HB).

[0095] Put TD01, TD01AB, TDH4P, TDH4ABP, TD68, TD68AB, TD68-194 and TD68-194AB in 10LB respectively, and TD01, TDH4P, TD68 and TD68-194 respectively in 60LB medium at 37°C, 200rpm, after 12 hours of culture , were inoculated into 50mL 10MMG and 60MMG medium at 1%, respectively, and 5g / L γ-butyrolactone was added as a carbon source at the same time, and cultured for 48 hours. After 48 hours, the bacteria were collected, and the dry cell weight and PHA content were detected. Three parallel samples were set for each experiment, and the results were averaged. T...

Embodiment 3

[0099] Example 3: Increase the content of P3HB4HB and cell dry weight in the fermentation broth of halophilic bacteria in low-salt medium. (by Halomonas bluephagenesis TDH4P series as an example)

[0100] The invention passes through the Halomonas bluephagenesis 4-Hydroxybutyryl-CoA transferase ( orf Z ) to synthesize 4HB-CoA, and in the cell's own PHA synthase ( phaC ) under the action of 3HB-CoA produced by its own metabolism to form P(3HB-co-4HB). On this basis, ARTP mutagenesis and low-salt stress screening were carried out, and PHA synthase from Eutropha rosenbergii was overexpressed on the plasmid and genome respectively ( phaC ), β-ketothiolase ( phaA ), NADH-type acetoacetyl-CoA reductase ( phaB ), the ultimate success was in obtaining strains that could grow and accumulate large amounts of PHA in low-salt media. Both dry weight and PHA content were increased.

[0101] Inoculate TDH4P, TDH4ABP, TDH4ABP+phaCAB (plasmid) and TDH4ABP+phaCAB (chromosome) in 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com