Steel plate for air conditioner compressor and production method thereof

An air-conditioning compressor and production method technology, applied in temperature control, metal rolling and other directions, can solve the problems of unqualified general regulations, high defective product rate, safety accidents, etc., and achieve the effect of good matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0043] Embodiment 1~6 is produced according to above-mentioned implementation mode,

[0044] The chemical composition and weight percentage of the produced steel grades are shown in Table 1, the process parameters of heating, rough rolling, finish rolling, and cooling are shown in Table 2 and Table 3, and the process parameters of the smoothing process are shown in Table 4. The mechanical properties of the plates are shown in Table 5.

[0045] Table 1

[0046]

[0047] Table 2

[0048]

[0049] table 3

[0050]

[0051] Table 4

[0052]

[0053] table 5

[0054]

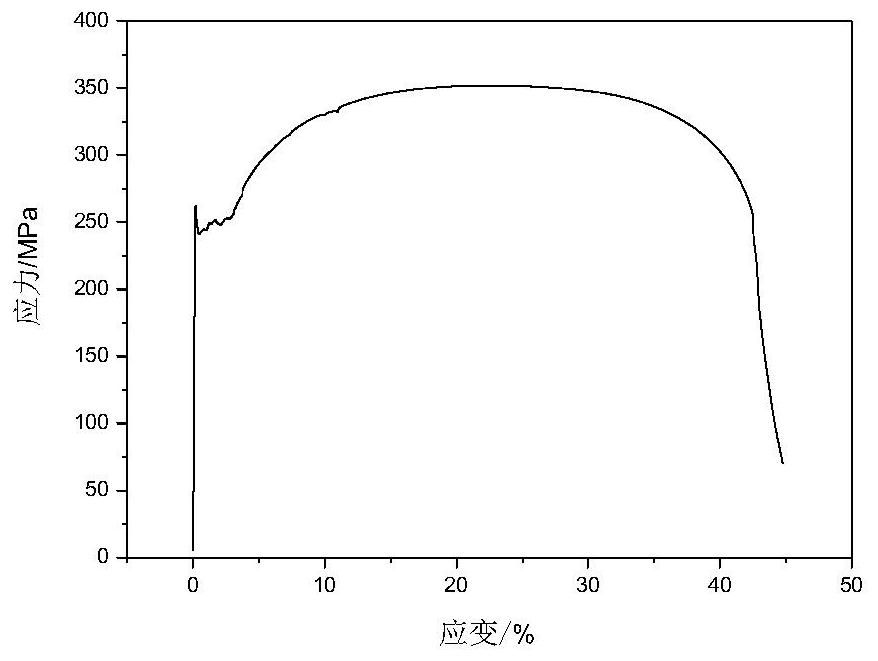

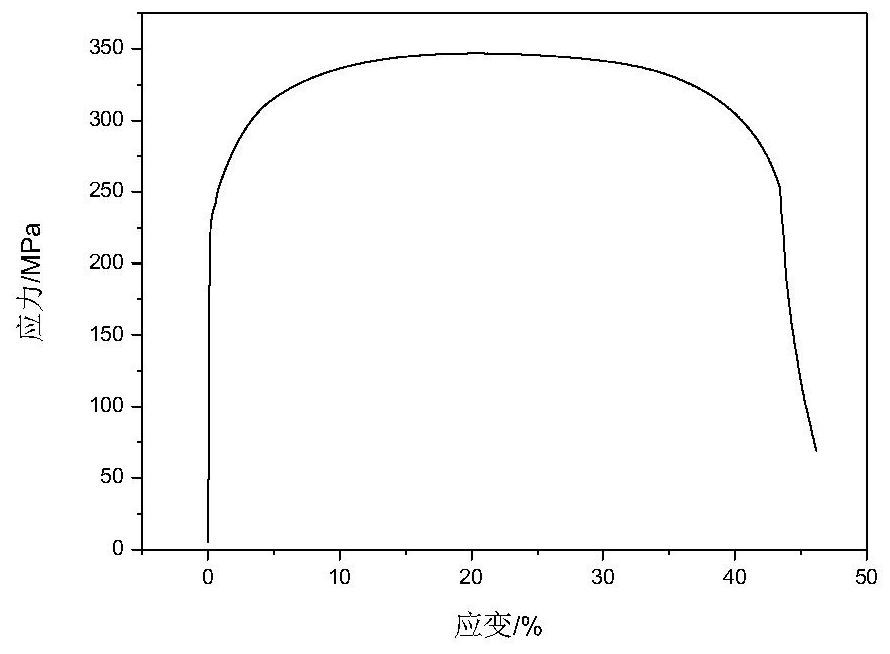

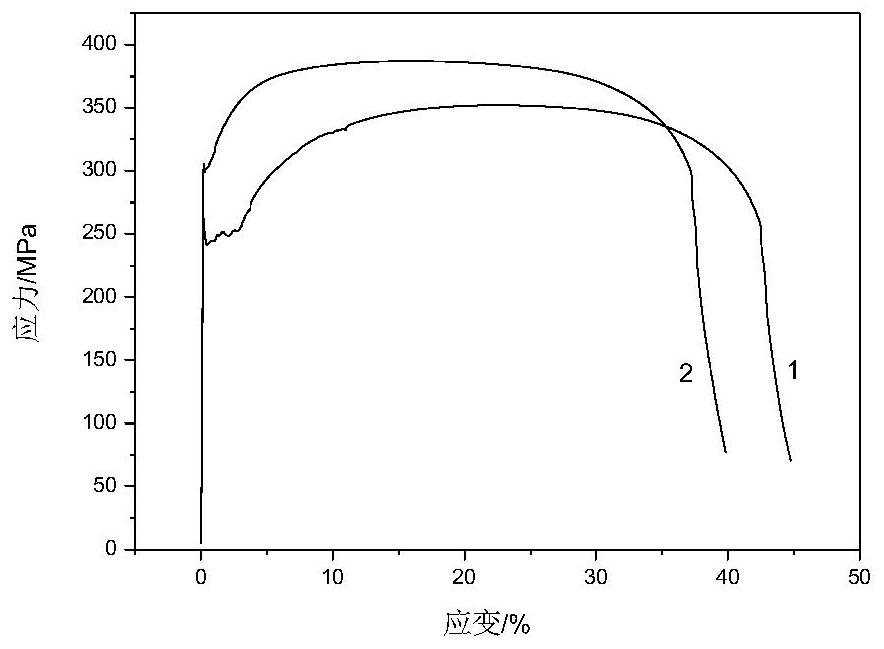

[0055] From attached Figure 5 ~ attached Figure 10 It can be seen that the microstructures obtained in Examples 1 to 6 are polygonal ferrite, and a small amount of carbides are precipitated at the grain boundaries. It can be seen from Table 5 that the yield strength of the pickling plate is 210~290MPa, the tensile strength is ≥300MPa, the elongation can reach 35~50%, the plate retains the yiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com