Self-spinning steel dam with centre rotating shaft

A central shaft and steel dam technology, used in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as affecting rapid interception or flood discharge, prone to quality accidents, and complex rubber dam production, to improve safety and reliability. , The shape is neat and beautiful, and the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

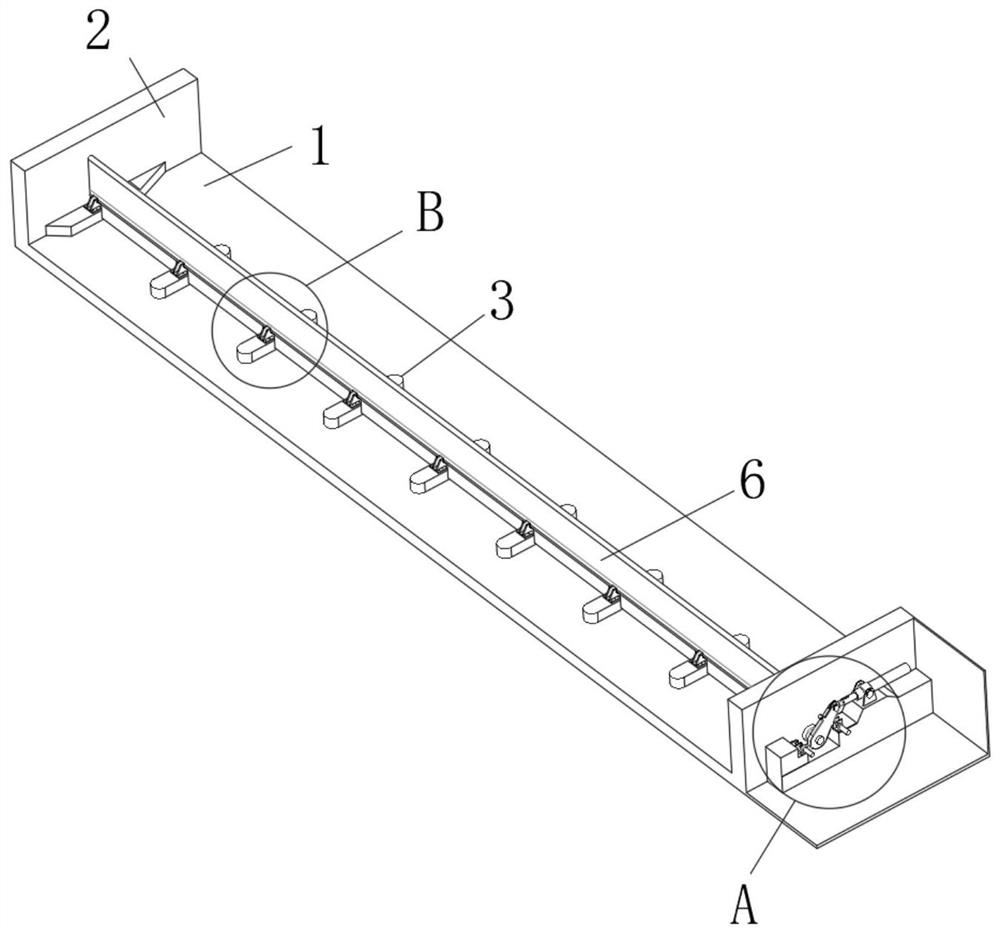

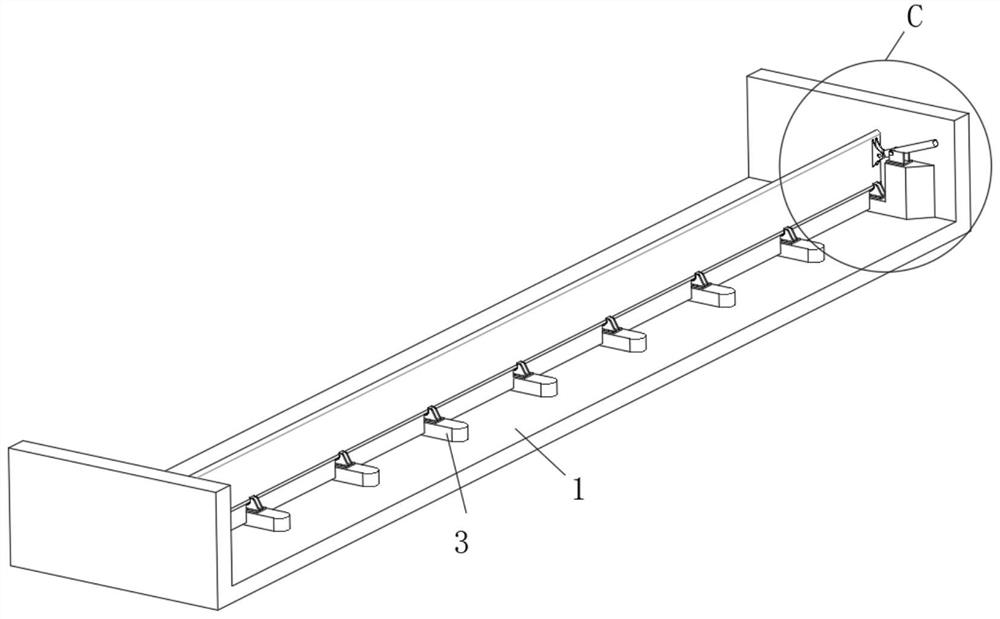

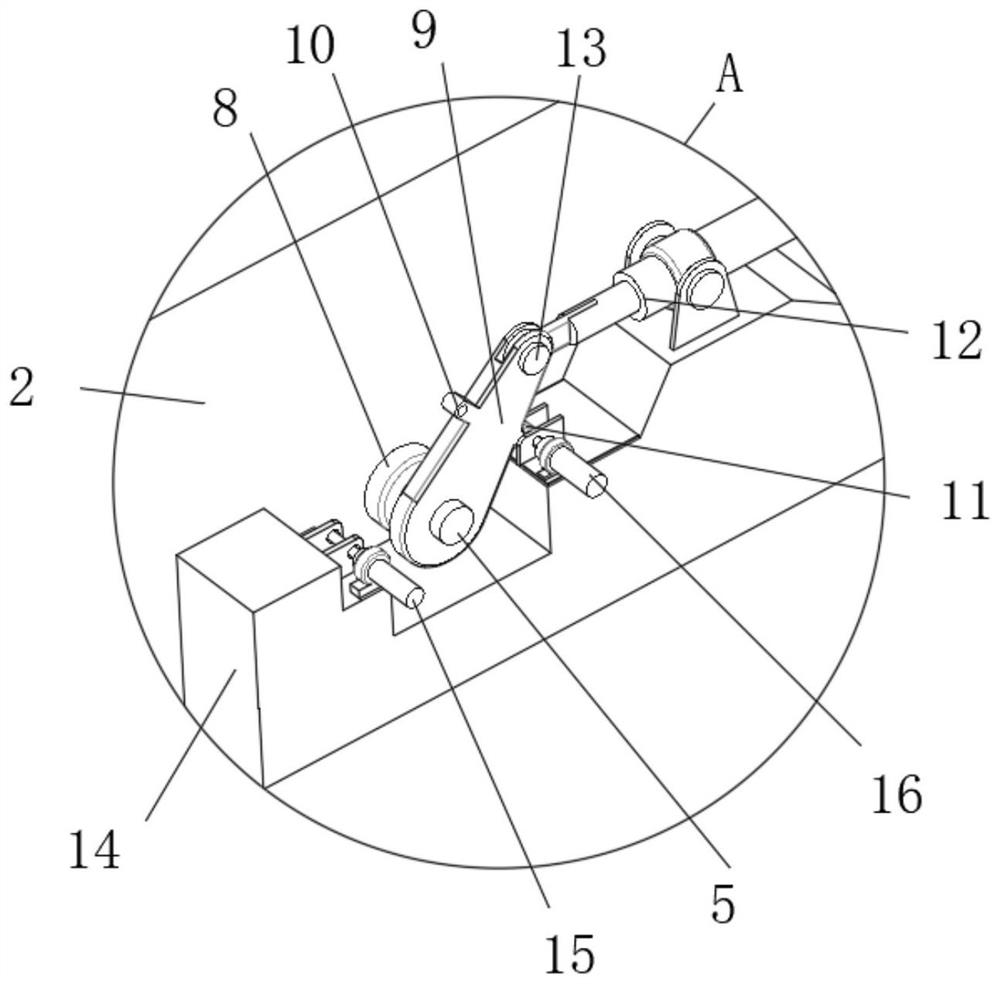

[0051] Example: Reference Figure 1-6 A central rotating shaft spinning steel dam shown includes a dam foundation 1, and also includes: side walls 2 arranged on both sides of the dam foundation 1; several supporting piers 3 are arranged on the top of the dam foundation 1; each supporting pier 3 There are foot support bushings 4 respectively; the rotating main shaft 5 passes through a plurality of foot supporting bushings 4; the rotating main shaft 5 is rotationally connected with the side wall 2; the panel assembly is connected with the rotating main shaft 5; connect.

[0052] The control assembly includes: crank arm 9, dam releasing limit hydraulic cylinder 15, dam erecting limit hydraulic cylinder 16, active power hydraulic cylinder 12, crank arm 9 is connected with rotating main shaft 5; one side of crank arm 9 is fixedly connected with a dam releasing The limit ring 10, the other side of the crank arm 9 is fixedly connected with the dam limit ring 11; the dam limit hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com