Few-support steel wire mesh reinforced microporous concrete non-dismantling bottom formwork and construction method thereof

A concrete and bottom formwork technology, which is applied to floors, building reinforcements, buildings, etc., can solve problems such as poor thermal insulation and anti-seepage, high construction cost, and low efficiency, and achieve large bending loads, improved construction efficiency, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

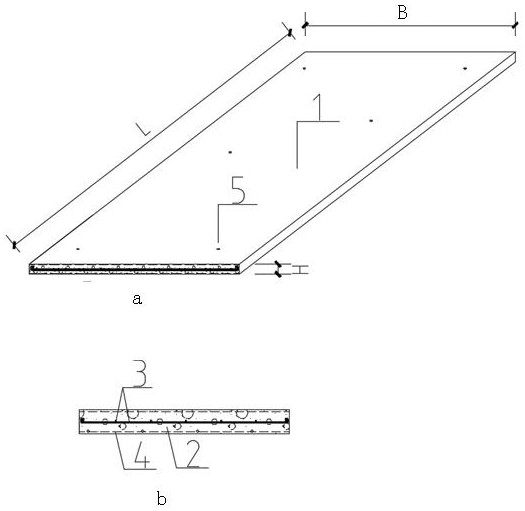

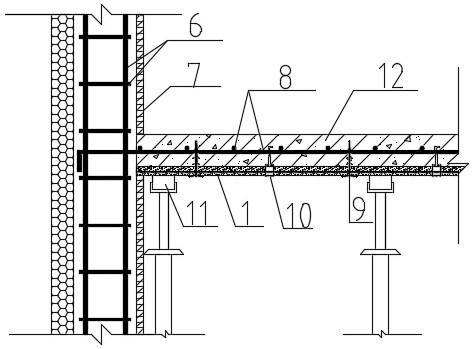

[0013] Such as Figure 1-3 As shown, a microporous concrete non-demolition-free bottom formwork 1 (abbreviated as non-demolition-free bottom formwork 1) reinforced with less-supported steel wire mesh for cast-in-place concrete floor slabs is composed of microporous lightweight concrete 2, φ4@100 steel mesh 3, durable Alkali glass fiber mesh cloth 4 is compounded without gaps, and it is used as a permanent demolition-free formwork 1 for cast-in-place concrete floor slabs. The ratio of board length L to width B is 2:1, and the thickness is 5cm.

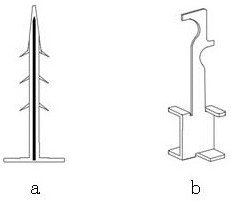

[0014] The invention discloses a construction method for a cast-in-place concrete floor slab with a less-supported steel wire mesh reinforced microporous concrete no-demolition bottom formwork 1. The non-demolition-free bottom formwork 1 is prefabricated according to the design size requirements and used as a permanent bottom formwork for a building's cast-in-place floor slab. During its construction, first determine the support spacin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com