Novel flash furnace sulfation device

A technology of sulfation and flash furnace, which is applied in the direction of furnace, furnace components, waste heat treatment, etc. It can solve the problems of difficult removal, strong adhesion of metal oxides, unfavorable safe operation of waste heat boiler, smooth exhaust of flash furnace, etc. problem, achieve the effect of lightening the load and reducing the loss of sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

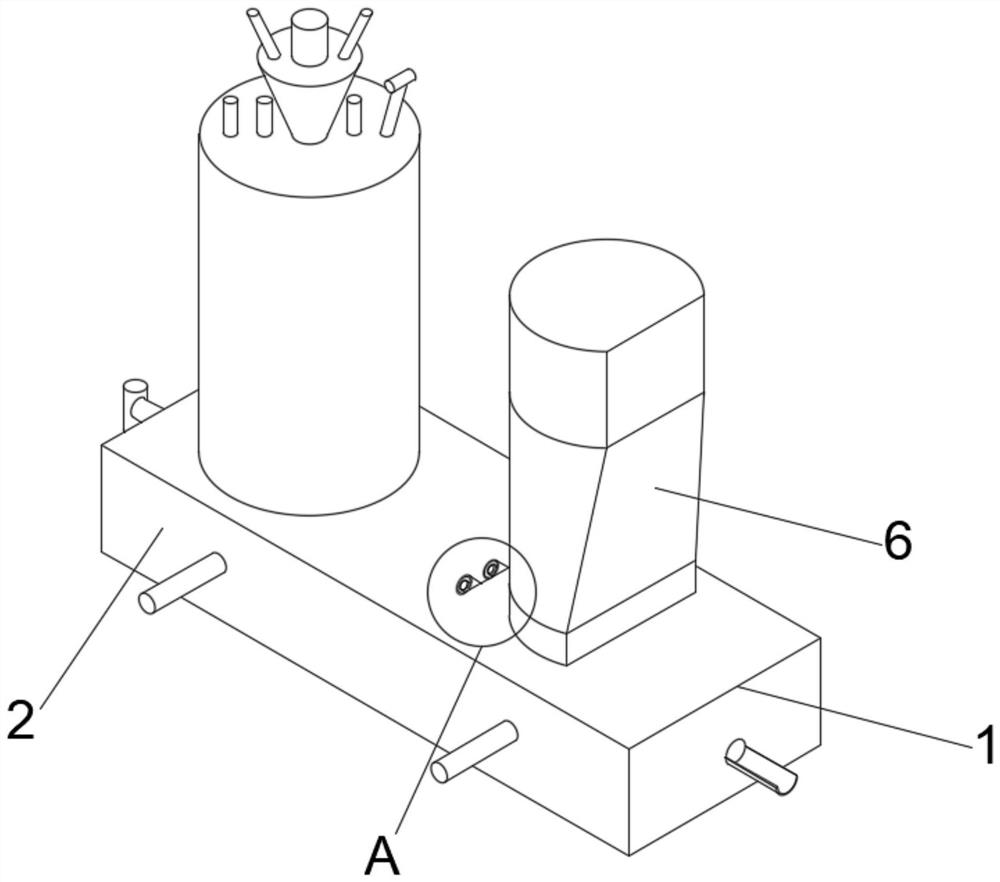

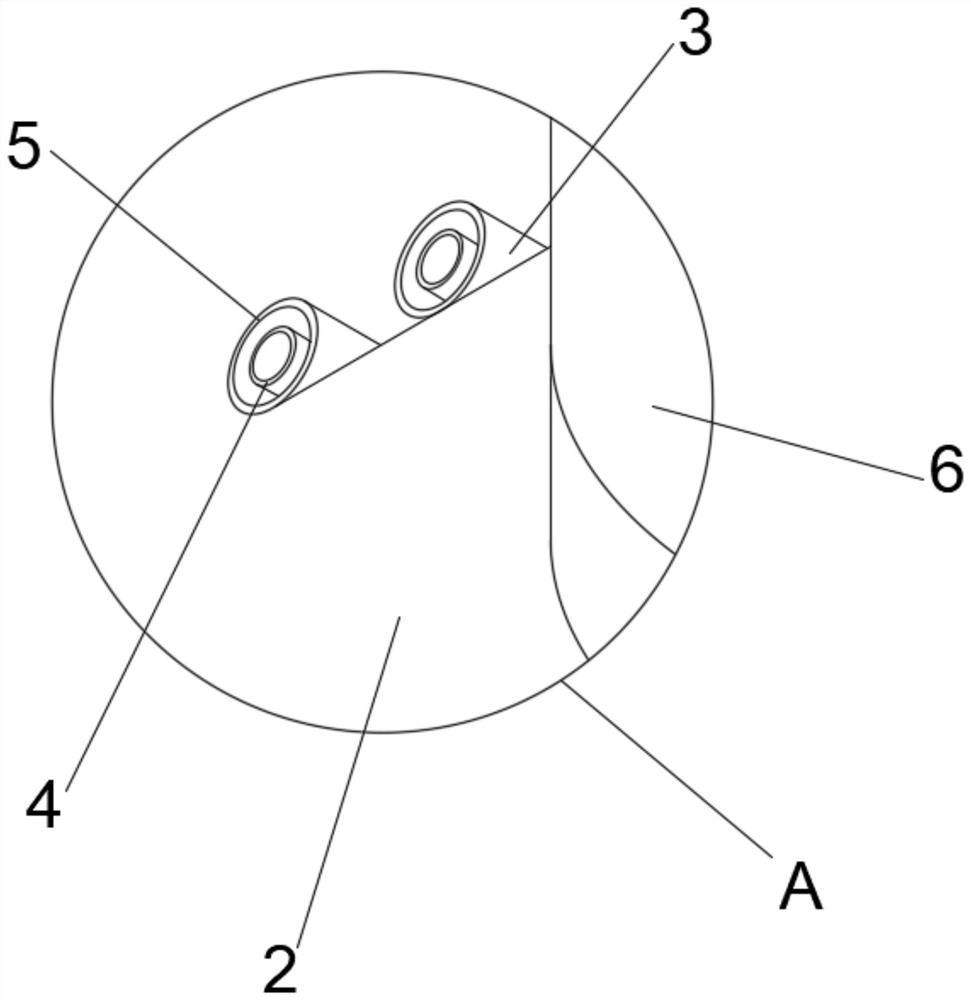

[0018] Such as Figure 1-2 Shown, a kind of novel flash furnace sulfation device of the present invention comprises flash furnace (1), and described flash furnace (1) comprises settling tank (2), ascending flue (6) and sulfuric acid The salinization unit (3), the sedimentation tank (2) and the sulphation unit (3) communicate with each other, and the sulphation unit (3) comprises a sleeve, and the sleeve comprises a DN50 white steel pipe (4) and DN25 white steel pipe (5), the DN25 white steel pipe (4) is arranged inside the DN50 white steel pipe (5), the casing is used to feed pure oxygen and dry air, and the sulfation device (3) is fixedly connected On the side near the uptake flue (6) at the top of the sedimentation tank (2), the number of the sulfation devices (3) is five, and the five sulfation devices (3) are arranged in the sedimentation tank (2) ) near the side of the ascending flue (6), the channel formed by the socketing of the DN50 white steel pipe (4) and the DN25 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com