Metallographic sample preparation and display method for iron-aluminum-silicon layer of aluminum-silicon coated steel plate

A coated steel plate and metallographic sample preparation technology, which is applied in the field of metal coating detection, can solve the problems of brittle coating, difficult sample preparation, and inability to guarantee the integrity of the coating, so as to achieve complete coating and low detection and analysis costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

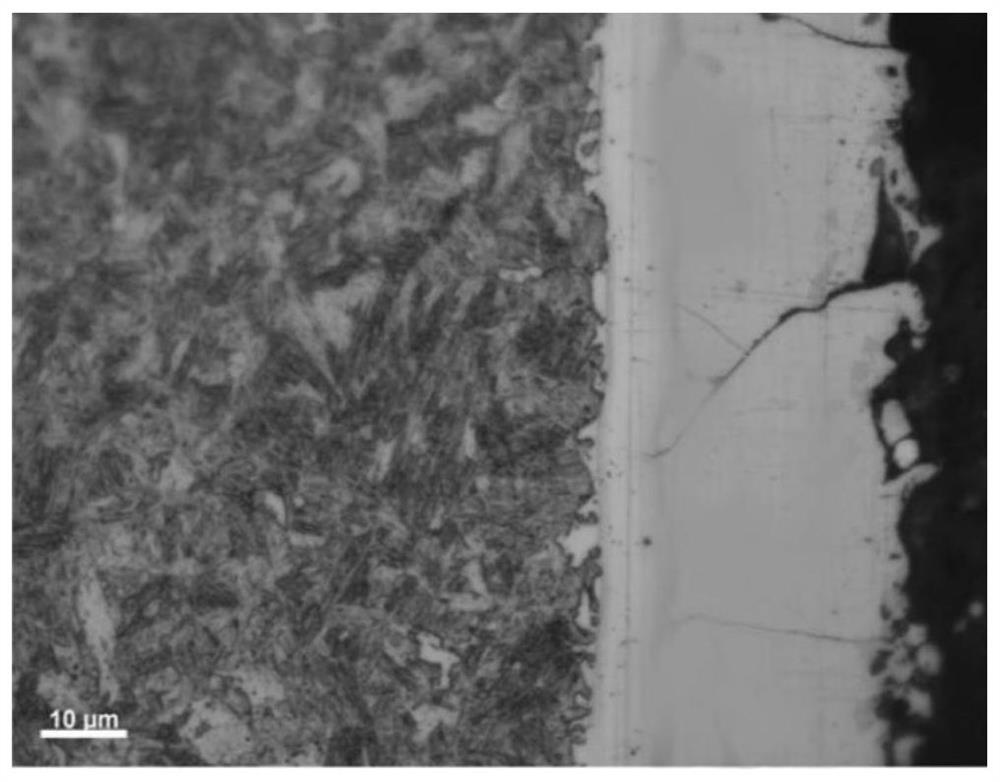

[0037] In this example, the aluminum-silicon coated steel plate (1500+AS grade), the metallographic sample preparation and display method of the metallographic structure of the iron-aluminum-silicon layer after hot stamping, including sample preparation, chemical corrosion and microscope observation, the specific process steps are as follows Said:

[0038] (1) Sample preparation:

[0039] Take the aluminum-silicon coated steel plate, scrape and coat a layer of Nippon topcoat with a thickness of about 20 μm on the surface of the steel plate with an RDS20 scraper rod, put it in a box-type drying furnace, keep the furnace temperature at 350 ° C, keep it for 50 seconds, and blow it with cold air after water cooling Dry; Cut a sample of 15mm×15mm by wire cutting, put the sample into the mosaic machine for mosaic;

[0040] Roughly grind the inlaid sample on a grinder until the surface is smooth and the scratches are of the same depth, and then smoothed on 280#, 400#, 600#, 800# met...

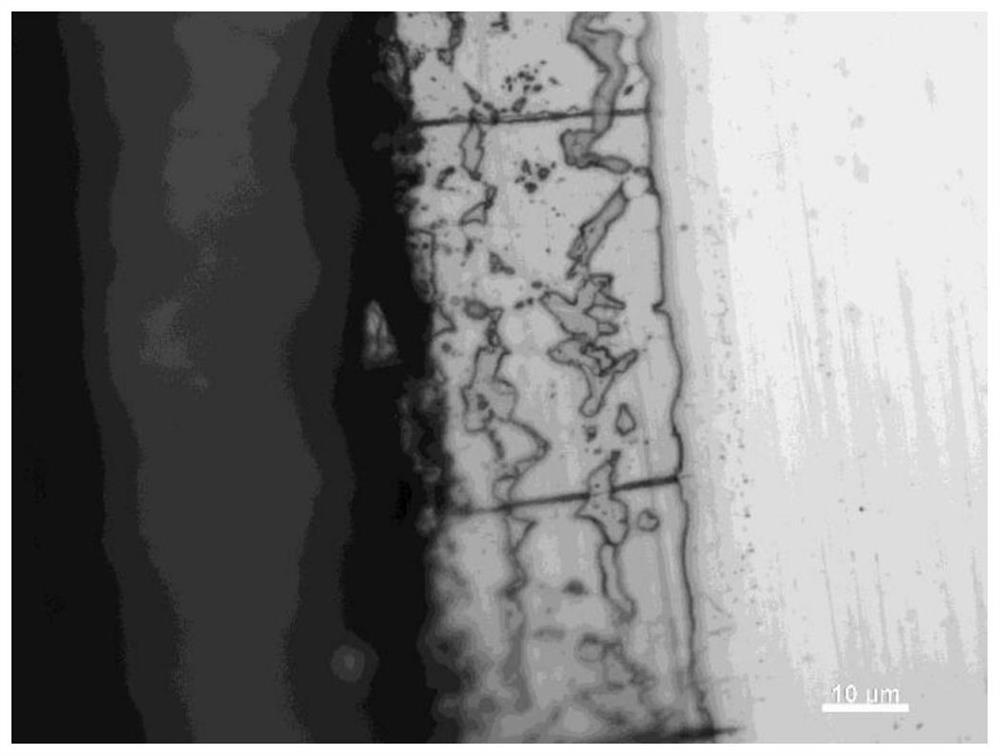

Embodiment 2

[0047] Take the aluminum-silicon-coated steel plate, scrape and coat a layer of Nippon topcoat with a thickness of about 35 μm on the surface of the steel plate with an RDS 35 scraper rod, put it in a box-type drying furnace, and dry it at a furnace temperature of 347 ° C, keep it for 52 seconds, and water-cool it. Afterwards, dry it with cold air; cut a sample of 10mm×10mm by wire cutting, and put the sample into the mosaic machine for mosaic;

[0048] Roughly grind the inlaid sample on a grinder until the surface is smooth and the scratches are of the same depth, and then smoothed on 280#, 400#, 600#, 800# metallographic sandpaper in turn, and the smoothing direction is perpendicular to the direction of the previous scratch;

[0049] Use a fine velvet polishing cloth evenly sprayed with 2.5 μm metallographic polishing agent to polish the sample, spray absolute ethanol while polishing, and the surface of the sample is bright without scratches after polishing for 86 seconds;

...

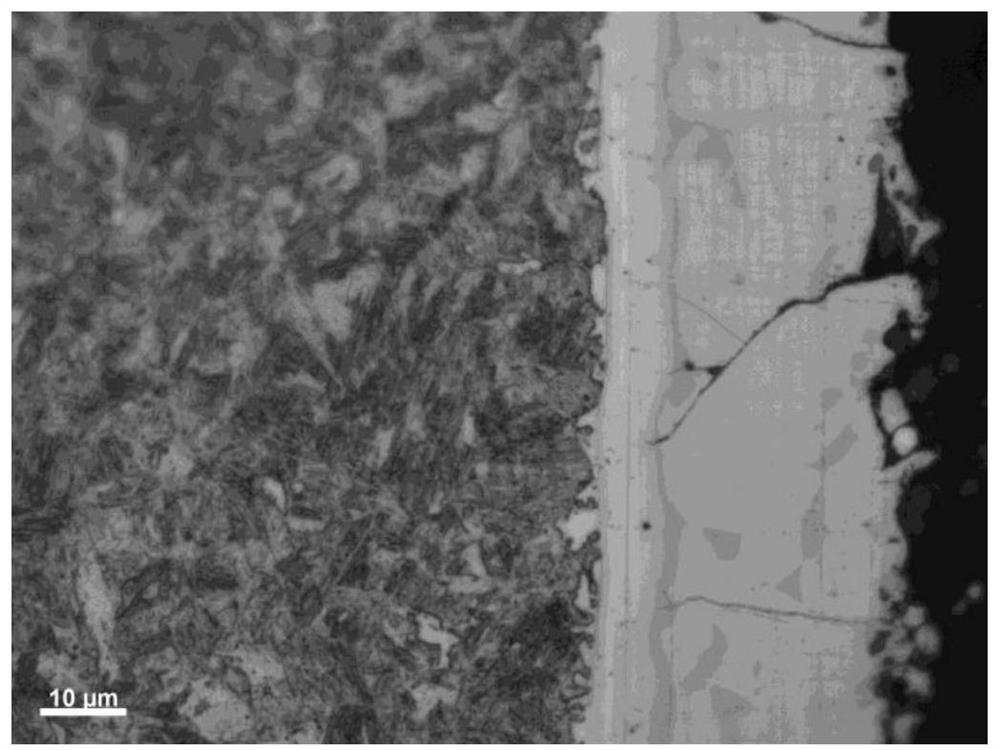

Embodiment 3

[0055] Take the aluminum-silicon coated steel plate, scrape and coat a layer of Nippon topcoat with a thickness of about 50 μm on the surface of the steel plate with an RDS50 scraper rod, put it in a box-type drying furnace, and dry it at a furnace temperature of 352 ° C, keep it warm for 47 seconds, and then water-cool it. Blow dry with cold air; cut a sample of 20mm×20mm by wire cutting, put the sample into the mosaic machine for mosaic;

[0056]Roughly grind the inlaid sample on a grinder until the surface is smooth and the scratches are of the same depth, and then smoothed on 280#, 400#, 600#, 800# metallographic sandpaper in turn, and the smoothing direction is perpendicular to the direction of the previous scratch;

[0057] Use a fine velvet polishing cloth evenly sprayed with 2.5 μm metallographic polishing agent to polish the sample, spray absolute ethanol while polishing, and the surface of the sample is bright without scratches after polishing for 110 seconds;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com