XRD (X-Ray Diffraction) method for determining wire texture

A texture and wire technology, which is applied in the field of wire texture measurement, can solve problems such as not being able to meet the requirements of wire texture measurement, and achieve the effect of ensuring information integrity and process improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

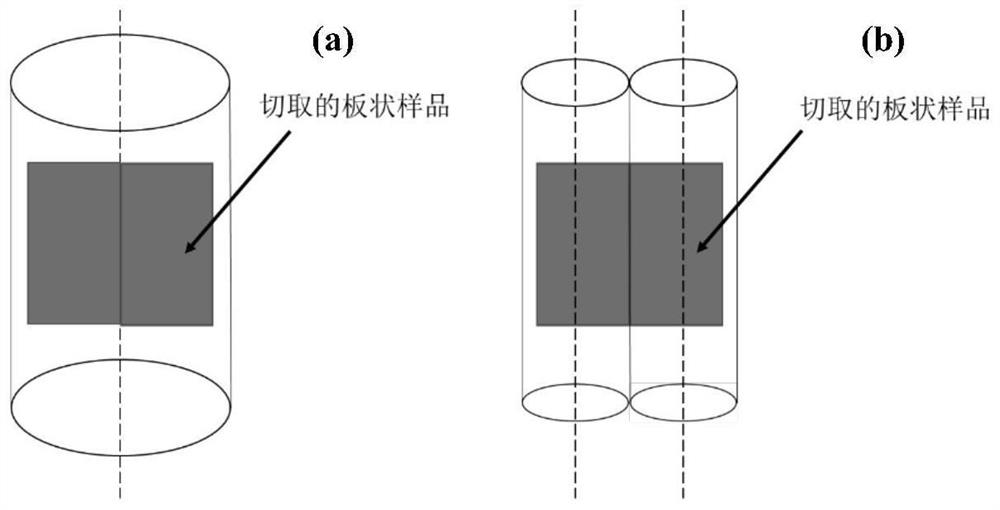

[0062] Use a wire electric discharge machine to cut a plate-shaped test sample with a length of 10mm from the center of the original wire rod along the longitudinal section;

[0063] Cut a plate-shaped standard sample with an area of 10mm×10mm from the standard sample using a wire electric discharge machine;

[0064] Use sandpaper to polish the surface of the cut plate-shaped test sample and plate-shaped standard sample to keep the surface of the sample smooth and flat;

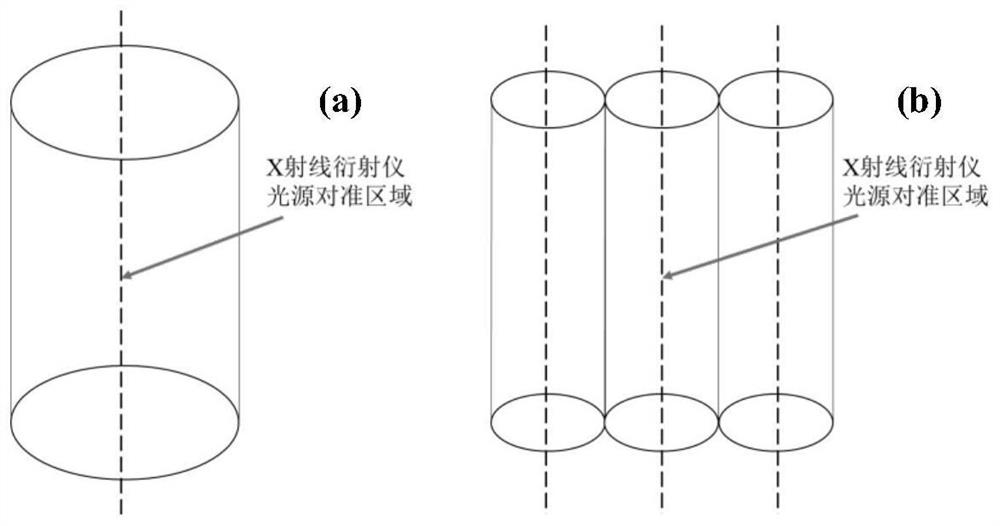

[0065] Use X-ray diffractometer to carry out the whole body texture measurement of three diffraction peaks (110), (200), (211) of ferrite to the smooth original wire rod plate sample of surface, measurement result is as follows Figure 4 shown;

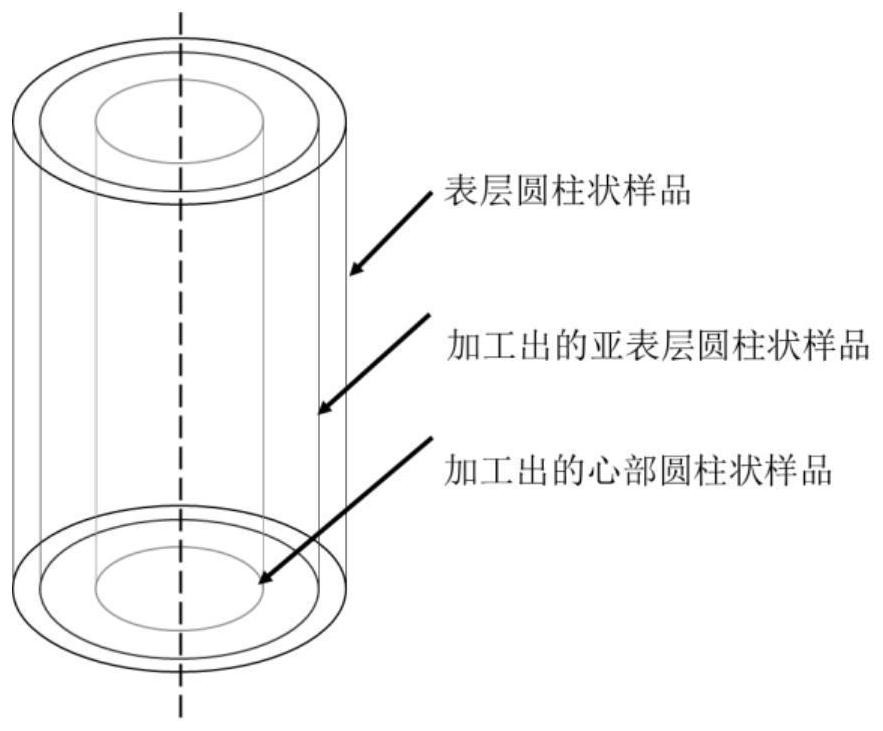

[0066] Use a lathe to process the original wire rod into cylindrical test samples with a length of 10mm and diameters of 13mm, 12mm and 6.5mm, respectively, which are surface cylindrical test samples, subsurface cylindrical test samples and core cylindrical test s...

Embodiment 2

[0079] Use a wire electric discharge machine to cut a plate-shaped test sample with a length of 10mm from the center of the cold-drawn steel wire along the longitudinal section;

[0080] Cut a plate-shaped standard sample with an area of 10mm×10mm from the standard sample using a wire electric discharge machine;

[0081] Use sandpaper to polish the surface of the plate sample to keep the surface of the sample smooth and flat;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com