Digital Metasurface Based on Periodic Torus-Parabolic Composite Hole Arrays

A parabolic and periodic technology, applied in optical components, instruments, optics, etc., can solve problems such as crosstalk, increase system size, etc., achieve the effect of small size, convenient operation, and expansion of application sites and adaptable scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

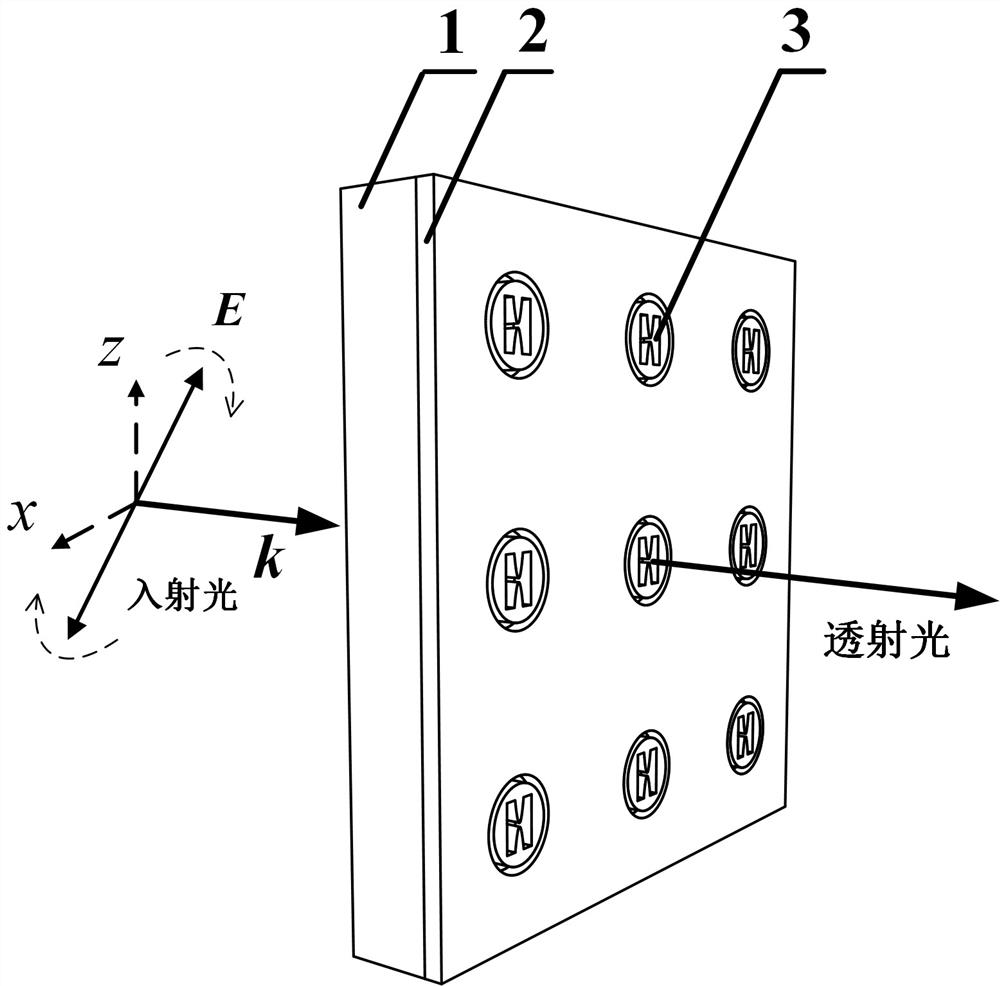

[0024] Example one, as Figure 1-4 As shown, a digital metasurface based on a periodic ring-parabolic composite hole array includes a dielectric substrate 1 and a metal thin film 2 , and the metal thin film 2 is disposed just above the dielectric substrate 1 .

[0025] The dielectric material of the dielectric substrate 1 is quartz, and the thickness of the quartz is 225 nm. The dielectric material of the dielectric substrate can also be any other dielectric suitable for processing, such as benzocyclobutene and the like.

[0026] The material of the metal thin film 2 is silver, and the thickness of the material silver of the metal thin film 2 is 50 nm. The material of the metal thin film 2 can also be other metals that can generate surface plasmons, such as gold and the like.

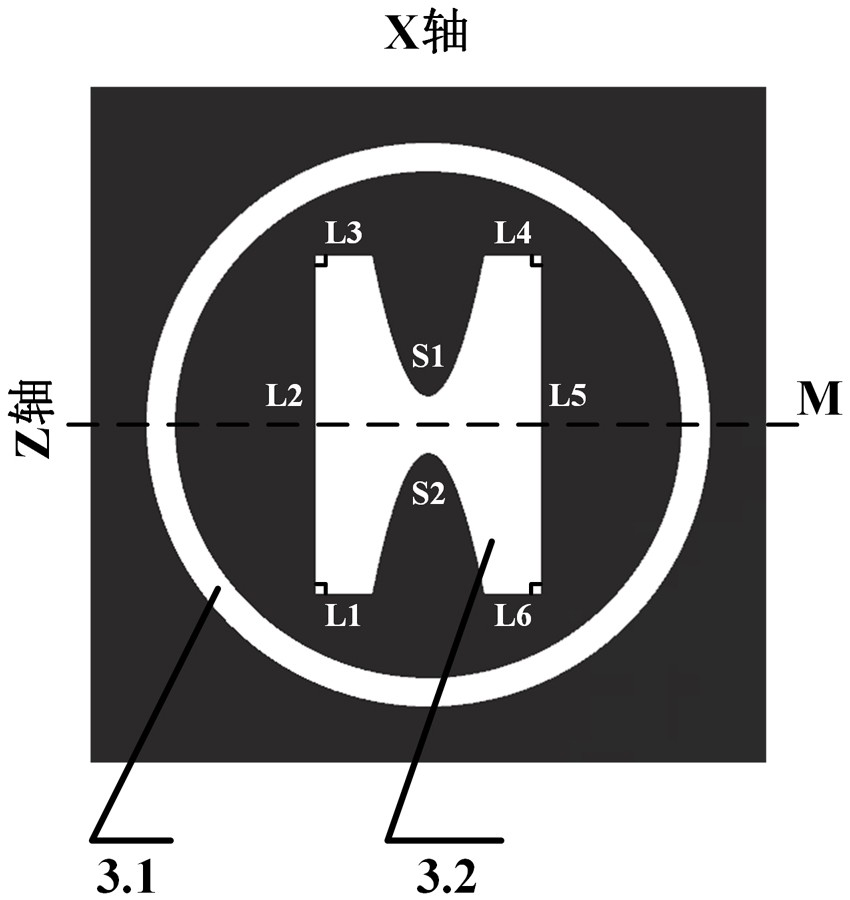

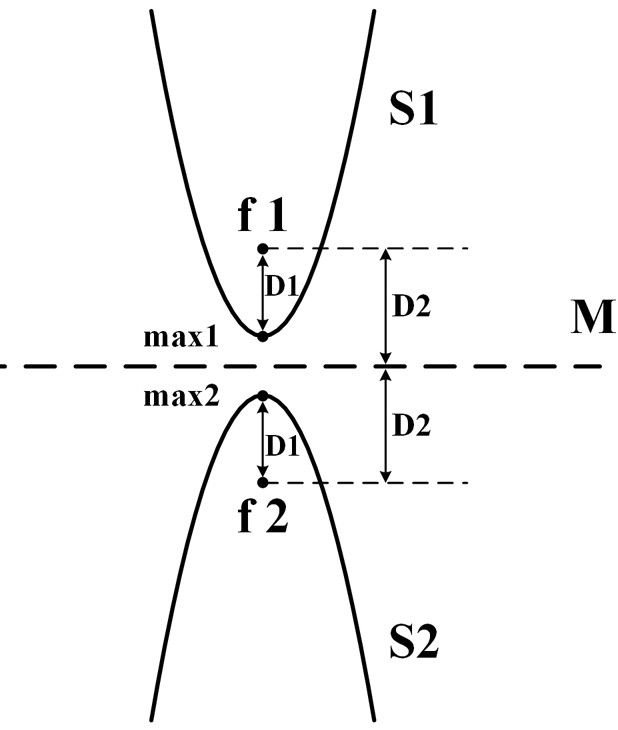

[0027] Nine ring-parabolic units 3 are etched on the metal film 2, and the nine ring-parabolic units 3 are arranged in a periodic array on the metal film 2. The nine ring-parabolic units 3 are 3×3 ar...

Embodiment 2

[0031] The second embodiment is similar in structure to the first embodiment, except that the dielectric material of the dielectric substrate 1 is quartz, the thickness of the quartz is 250 nm, the material of the metal thin film 2 is silver, and the thickness of the material silver of the metal thin film 2 is set. is 60 nm, the arrangement period of the ring-parabolic unit 3 is 300 nm, the inner radius of the ring 3.1 is 101 nm, and the width of the ring 3.1 is 23 nm, that is, the outer radius of the ring 3.1 is 124 nm. The length of the second straight side L2 of the parabolic hole 3.2 is equal to the length of the fifth straight side L5, and both are 140 nm. The lengths of the first straight side L1 , the third straight side L3 , the fourth straight side L4 and the sixth straight side L6 are equal to 25.5 nm. The distance D1 from the extreme points (vertices) max1 and max2 of the first parabolic side S1 and the second parabolic side S2 to the focal points f1 and f2 is 2.5 n...

Embodiment 3

[0032] The third embodiment is similar in structure to the first embodiment, except that the dielectric material of the dielectric substrate 1 is quartz, the thickness of the quartz is 350 nm, the material of the metal thin film 2 is silver, and the thickness of the silver of the material of the metal thin film 2 is set. is 150 nm, the arrangement period of the ring-parabolic unit 3 is 900 nm, the inner radius of the ring 3.1 is 250 nm, and the width of the ring 3.1 is 60 nm, that is, the outer radius of the ring 3.1 is 310 nm. The length of the second straight side L2 of the parabolic hole 3.2 is equal to the length of the fifth straight side L5, and both are 300 nm. The lengths of the first straight side L1 , the third straight side L3 , the fourth straight side L4 and the sixth straight side L6 are equal to 54.3 nm. The distance D1 from the extreme points (vertices) max1 and max2 of the first parabolic side S1 and the second parabolic side S2 to the focal points f1 and f2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com