Cold-rolled copper strip surface defect recognition model training method, cold-rolled copper strip surface defect recognition method and system

A technology for identifying models and training methods, applied in neural learning methods, character and pattern recognition, biological neural network models, etc., can solve problems such as poor application effect and few defect categories, and achieve fast recognition speed, good application effect, The effect of high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

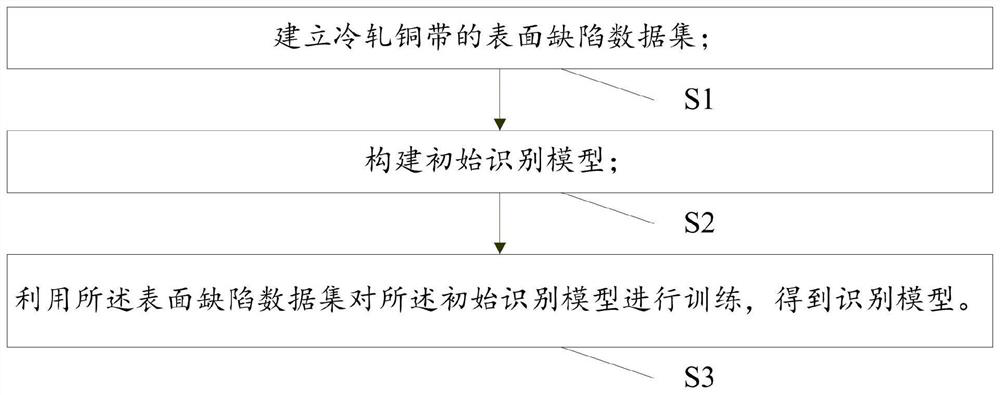

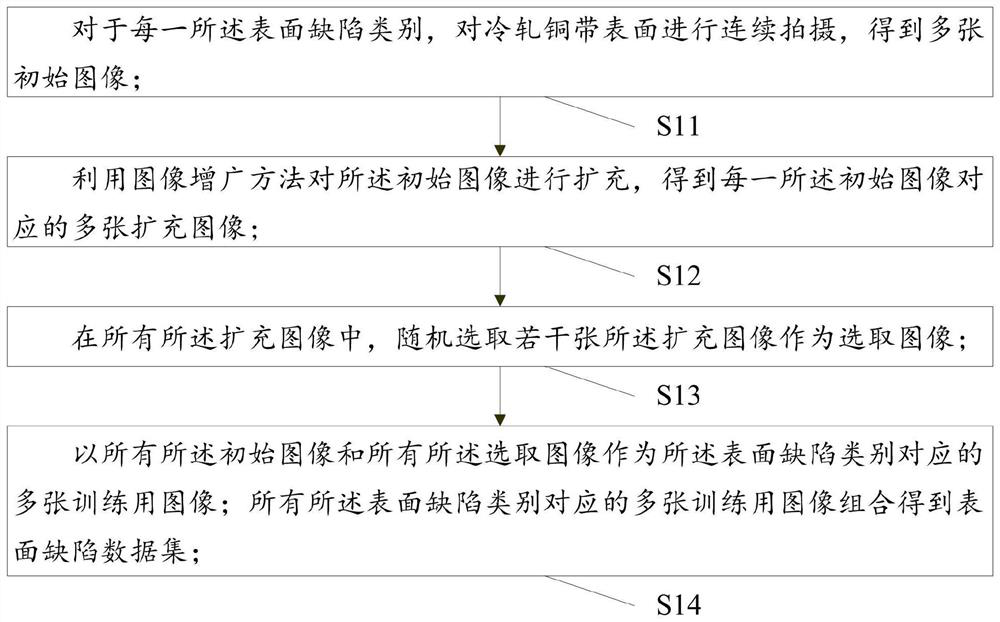

[0035] Compared with traditional machine vision methods, deep learning methods have better nonlinear learning perception ability and generalization anti-interference ability, and can well overcome the shortcomings of traditional methods. Therefore, this embodiment adopts a deep learning method to establish a recognition model, such as figure 1 As shown, the present embodiment is used to provide a cold-rolled copper strip surface defect recognition model training method, the training method comprising:

[0036] S1: Establish a surface defect data set of cold-rolled copper strip; the surface defect data set includes a plurality of training images corresponding to various surface defect categories;

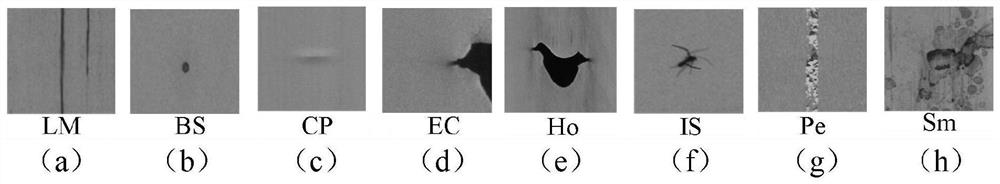

[0037] Before S1, the training method of this embodiment also includes: according to actual needs, selecting lines, black spots, bumps, edge cracks, holes, insect spots, peeling and dirt as the surface defect categories included in the surface defect data set . Specifically, there ...

Embodiment 2

[0088] This embodiment is used to provide a method for identifying defects on the surface of a cold-rolled copper strip, such as Figure 9 As shown, the identification method includes:

[0089] T1: Obtain the image to be recognized corresponding to the cold-rolled copper strip;

[0090] Specifically, the acquisition process is that at the end of the cold-rolled copper strip cleaning line and before the coiling unit, multiple sets of high-speed cameras are used to continuously shoot the surface of the copper strip to obtain images to be recognized.

[0091] T2: Using the image to be recognized as input, use the recognition model trained in Embodiment 1 to perform real-time recognition on the image to be recognized to obtain the surface defect category corresponding to the image to be recognized.

[0092] At the same time, the captured original image information, recognition result information, and strip property information are displayed and stored in the computer in real time...

Embodiment 3

[0096] This embodiment is used to provide a system for identifying defects on the surface of a cold-rolled copper strip, such as Figure 11 As shown, the identification system includes:

[0097] The acquisition module M1 is used to acquire the image to be identified corresponding to the cold-rolled copper strip;

[0098] The acquisition process is that at the end of the cold-rolled copper strip cleaning line and before the coiling unit, multiple sets of high-speed cameras are used to continuously photograph the surface of the copper strip.

[0099] The identification module M2 is configured to use the image to be identified as an input, and use the identification model trained in Embodiment 1 to identify the image to be identified in real time to obtain the surface defect category corresponding to the image to be identified.

[0100] At the same time, the captured original image information, recognition result information, and strip property information are displayed and stor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap