A kind of solid-liquid hybrid capacitor and its preparation method

A solid-liquid mixing and capacitor technology, which is applied in the manufacture of electrolytic capacitors, capacitors, capacitor electrodes, etc., can solve problems such as the difficulty of impregnation steps, and achieve the effect of reducing the difficulty of impregnation and expanding the upper limit of size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the existing solid-liquid hybrid capacitor comprises the following steps:

[0030] S10: Cut the positive electrode foil, negative electrode foil and electrolytic paper to a preset width;

[0031] S20: Roll the positive electrode foil, the negative electrode foil and the electrolytic paper into a core package;

[0032] S30: Forming the core pack to obtain the formed core pack;

[0033] S40: performing pressure impregnation on the formed core pack to obtain an impregnated core pack;

[0034] S50: drying the impregnated core pack to obtain a dried core pack;

[0035] S60: the dried core is impregnated with the electrolyte to obtain the core package impregnated with the electrolyte;

[0036] S70: Assemble the core pack impregnated with the electrolyte, the aluminum shell and the leather plug to obtain a semi-finished capacitor;

[0037] S80: Charge and age the semi-finished capacitor to obtain a solid-liquid hybrid capacitor.

[0038] Since th...

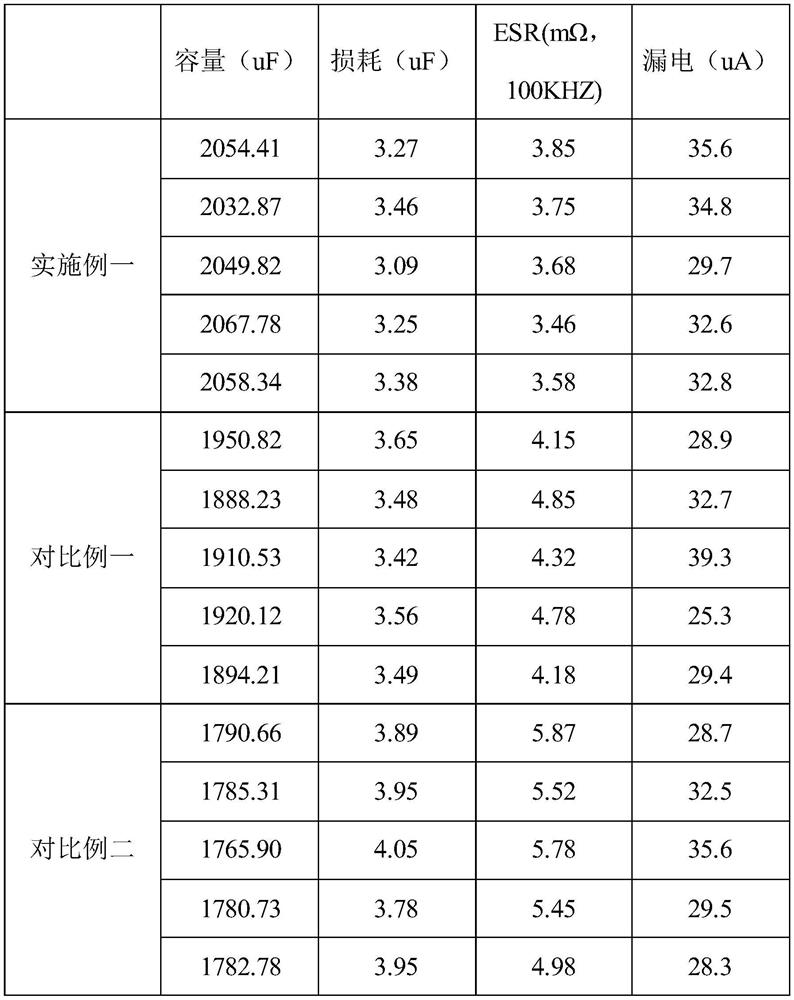

Embodiment 1

[0070] This embodiment provides a preparation method of a 25V2200 16*30 solid-liquid hybrid capacitor, which includes the following steps:

[0071] S1: Cut the negative electrode foil to a width of 21 mm, and cut the electrolytic paper to a width of 24 mm.

[0072] S2: Cut the positive electrode foil to a width of 21mm. Before winding, it is formed twice through the formation tank. The voltage of the first formation is 0.5 times the voltage of the positive foil (22V), and the time for restoration is 3 minutes; The electrification voltage of the secondary formation is the positive electrode foil voltage + 1VF (46V), and the electrification and formation repair time is 3 minutes; the formation solution is an aqueous solution of ammonium adipate with a mass concentration of 8%; after the formation of the positive electrode foil, the formed positive electrode is obtained foil;

[0073] S3: Roll the negative electrode foil, the electrolytic paper and the formed positive electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com