Fine dried noodle racking mechanism and airing rack integrated device

A technology for drying racks and dried noodles, which is applied in the fields of dough processing, baking, food science, etc. It can solve the problems of complex mechanical structure and troublesome drying of dried noodles, and achieve the effects of reasonable structural design, convenient hanging of dried noodles and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

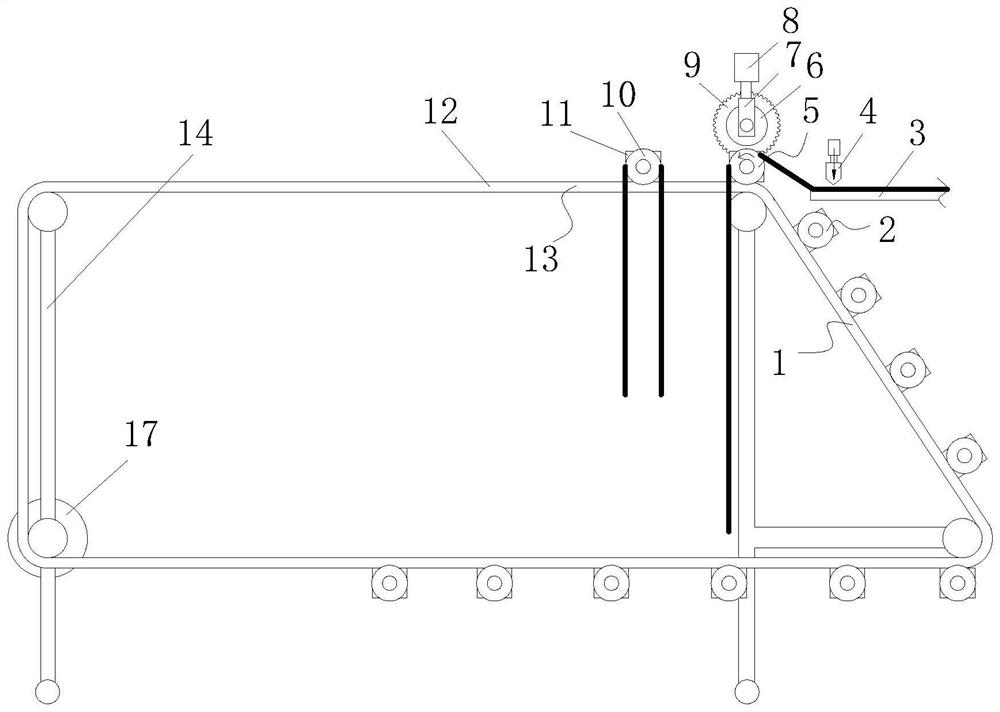

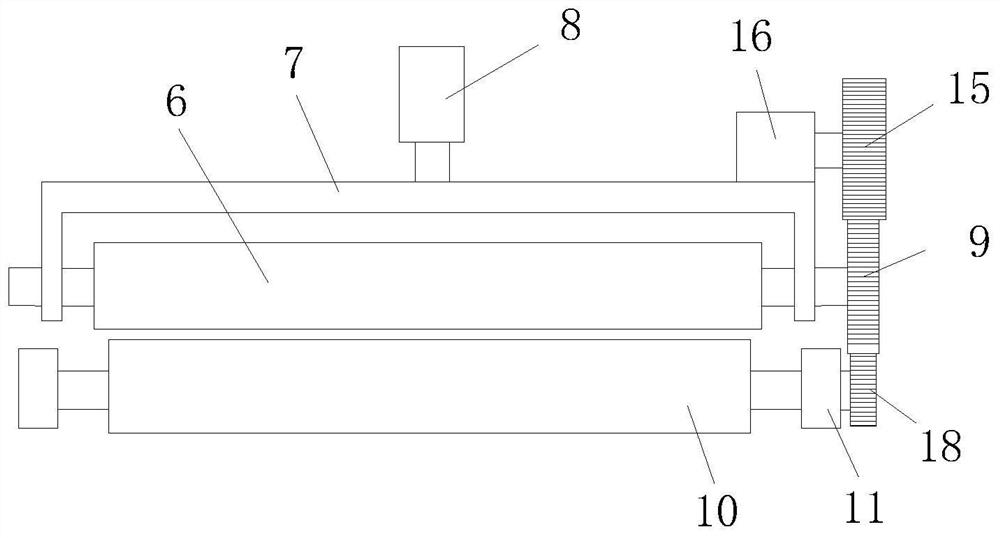

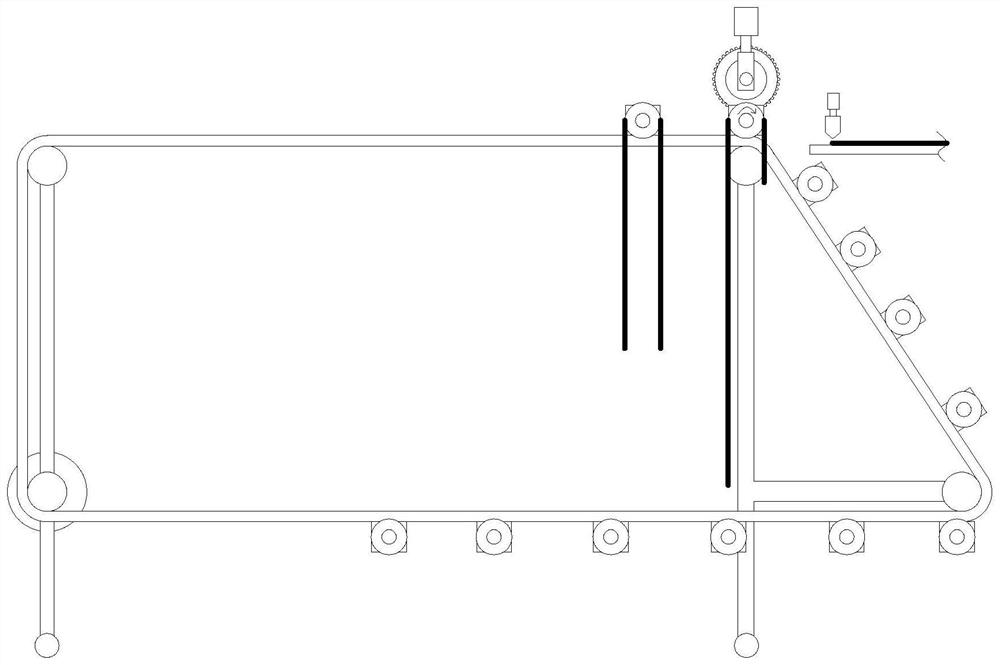

[0029] As an embodiment of the transmission mechanism: the transmission mechanism includes a telescopic cylinder 8 affixed to the frame 14, the bottom end of the piston rod of the telescopic cylinder 8 is affixed to a bracket 7, and the bracket 7 is rotatably connected to a pressure rod parallel to the support rod 10 6. The pressure rod 6 cooperates with the support rod 10 of the second assembly 5. One end of the pressure rod 6 is coaxially fixed with the first gear 9, and one end of the support rod 10 is coaxially fixed with the third gear meshing with the first gear 9 18. Between the first gear 9 and the bracket 7, there is a power mechanism for driving the forward and reverse movement of the first gear 9. The telescopic cylinder 8 drives the pressure rod 6 to move up and down, and the pressure rod 6 moves upward to separate from the second component 5. Then the second motor 17 drives the conveyor chain to move, so that the second assembly 5 moves a station, and the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com