Automatic acid cleaning device and method for glassware

A glassware and acid cleaning technology, which is applied in the field of laboratory cleaning, can solve the problems of hidden safety hazards for operators, unclean air, and large acid consumption, and achieve the effects of protecting safety, reducing work burden, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

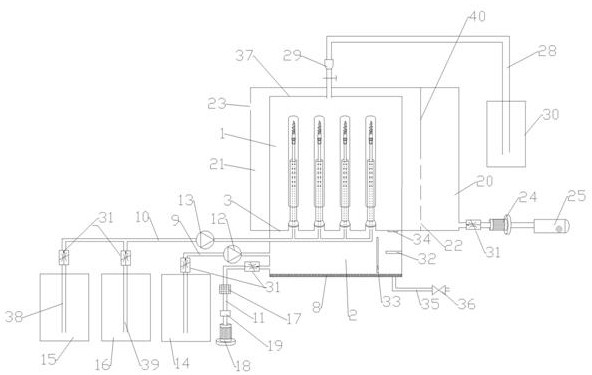

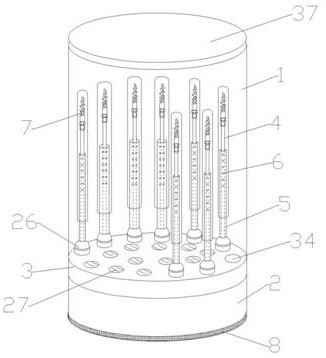

[0037] A fully automatic acid cleaning device for glassware, comprising an acid steam cleaner and a condensation chamber, the acid steam cleaner includes a cleaning chamber 1 and an acid steam generating chamber 2 arranged below the cleaning chamber 1, and the cleaning chamber 1 is arranged in the condensation chamber ;

[0038] A cleaning frame is fixedly arranged in the cleaning chamber 1. The cleaning frame includes a cylindrical support plate 3 and a number of cleaning tubes arranged above the support plate 3. Each cleaning tube includes a long cleaning tube 4 and a short cleaning tube sleeved on the long cleaning tube 4. The cleaning pipe 5; the short cleaning pipe 5 and the long cleaning pipe 4 are hollow cylindrical structures with upper and lower openings, and the upper part of the outer wall of the short cleaning pipe 5 is provided with a number of exhaust holes 6 for discharging acid vapor; the long cleaning pipe 4 There is a spiral nozzle 7 on the top, which is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com