Automobile hub clamp, machining equipment and production line

A technology of automobile wheel hub and processing equipment, applied in metal processing equipment, metal processing, metal processing mechanical parts, etc., can solve the problems of low processing accuracy, high processing cost, cutting fluid splash, etc., to ensure accuracy and quality, contact area Guarantee and reduce the effect of waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

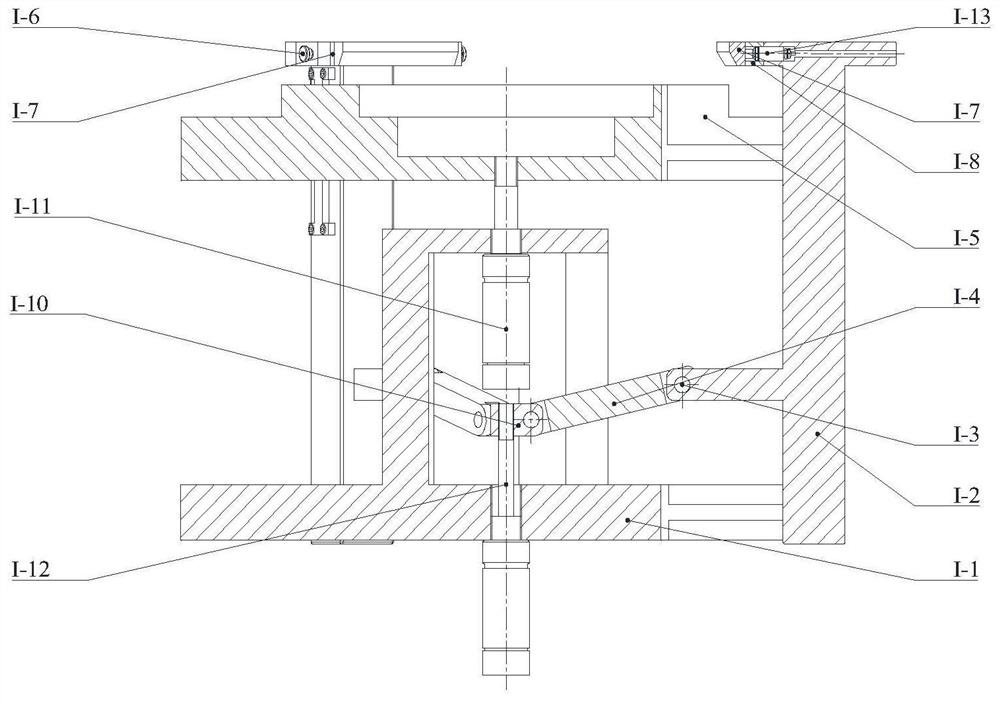

[0058] This embodiment provides a kind of automobile wheel clamp, as Figure 1-Figure 3 As shown, it includes a clamp main body and a positioning device I-5, the positioning device I-5 is used for positioning the hub V, and the clamp main body is used for clamping the hub V.

[0059] Specifically, the clamp body includes a fixed platform I-1, a clamping claw I-2, a linkage mechanism, etc., and multiple clamping claws I-2 are installed along the circumference of the fixed platform I-1, and the clamping claw I-2 is connected The rod mechanism is connected with the cylinder I-12, and the connecting rod mechanism is driven by the cylinder I-12 to make the clamping claw I-2 clamp or loosen the hub V.

[0060] Further, such as Figure 4-Figure 6 As shown, the fixed platform I-1 is used to connect the spindle of the machine tool, and multiple installation grooves are evenly opened in its circumference, and the two sides of the installation groove are symmetrically installed on the t...

Embodiment 2

[0072] This embodiment provides an automobile hub clamp, including a clamp body and a positioning device I-5, the positioning device I-5 is used for positioning the wheel hub V, and the clamp body is used for clamping the wheel hub V. Wherein, the main structure of the fixture is the same as that of the first embodiment, and will not be repeated here.

[0073] Such as Figure 9 and Figure 10 As shown, the positioning device 1-5 includes a movable platform 1-5-2 and a positioning module, and the positioning module includes a positioning block 1-26, a cylinder 1-27, a first connecting rod 1-28, a second connecting rod 1-25, etc. , the shape of the movable platform I-5-2 is adapted to the fixed platform I-1, and the circumferential direction of the movable platform I-5-2 is corresponding to the installation groove of the fixed platform I-1. The installation groove of 2 forms mobile pair with movable part 1-9.

[0074] In this embodiment, the movable platform I-5-2 is set in t...

Embodiment 3

[0078] This embodiment provides an automobile hub clamp, including a clamp body and a positioning device I-5, the positioning device I-5 is used for positioning the wheel hub V, and the clamp body is used for clamping the wheel hub V. Wherein, the main structure of the fixture is the same as that of the first embodiment, and will not be repeated here.

[0079] Such as Figure 11 Shown, positioning device 1-5 comprises movable platform 1-5-3 and positioning module, and positioning module comprises positioning plate 1-31, spring 1-34, and the shape of movable platform 1-5-3 is similar to fixed platform 1-1. To adapt, the movable platform I-5-3 is set to a truncated cone shape, and its raised part is used to be inserted into the V inner ring of the hub. Movable platform I-5-3 circumferential direction is corresponding to the installation groove of fixed platform I-1 and offers installation groove equally, and the installation groove of movable platform I-5-3 forms mobile pair wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com