Metal dot matrix reinforced ablative material sandwich plate structure

A metal lattice and ablation material technology, which is applied in the direction of metal layered products, layered products, aerospace safety/emergency devices, etc., can solve problems such as poor reliability, low strength and fracture toughness, and risk of interface connection. Achieve the effect of eliminating the risk of failure, slowing down the mass ablation rate, and realizing the structure lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

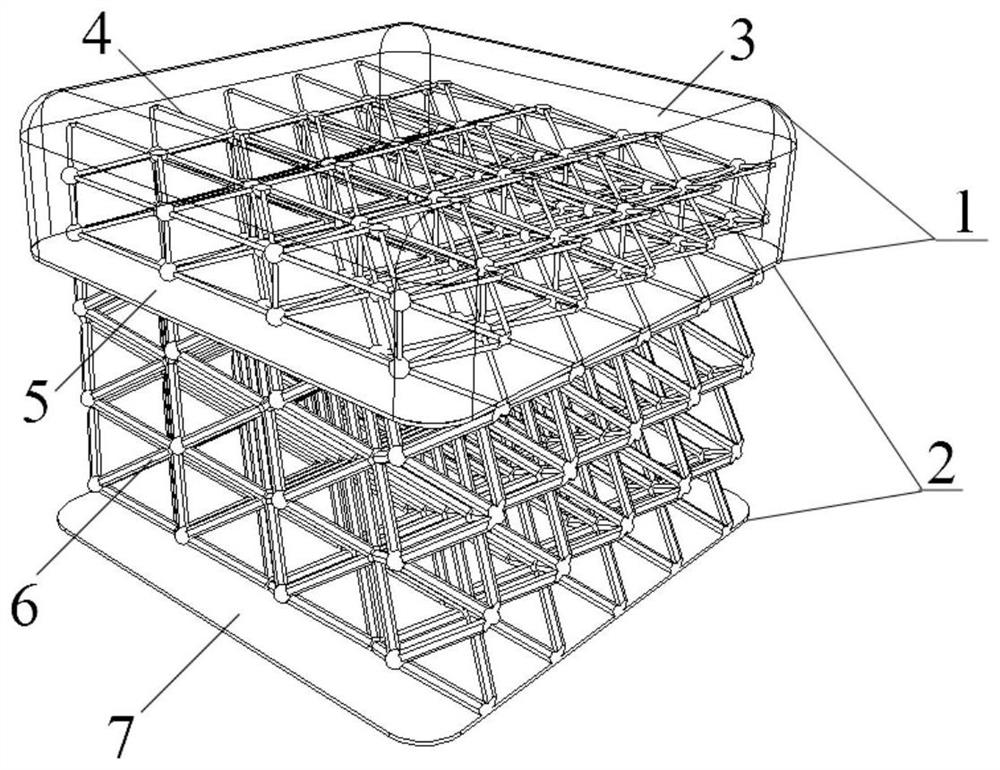

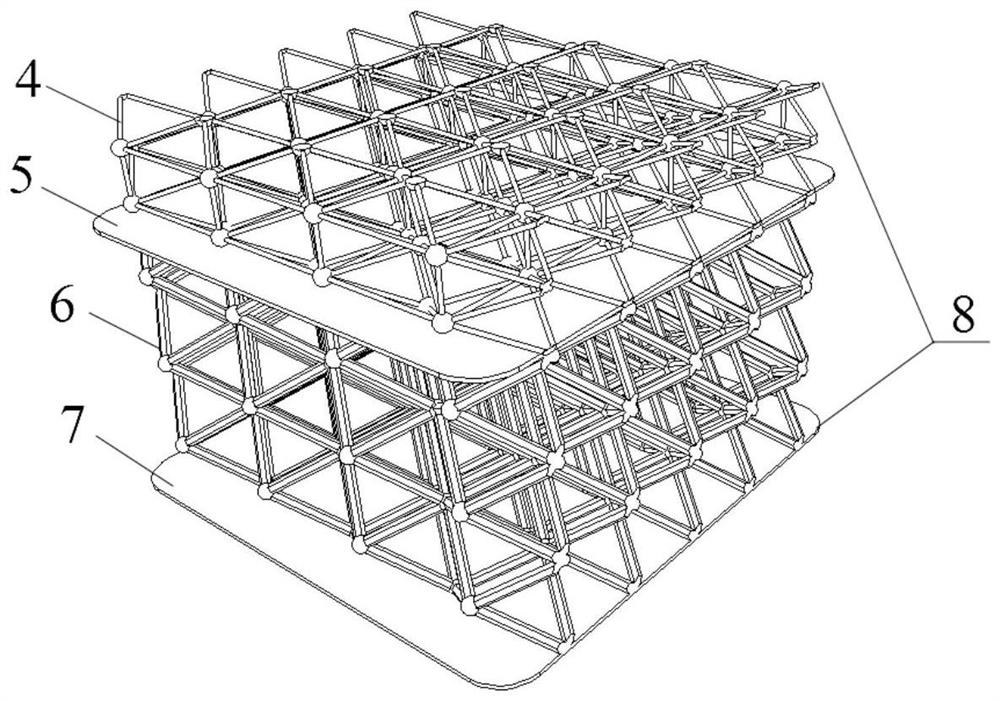

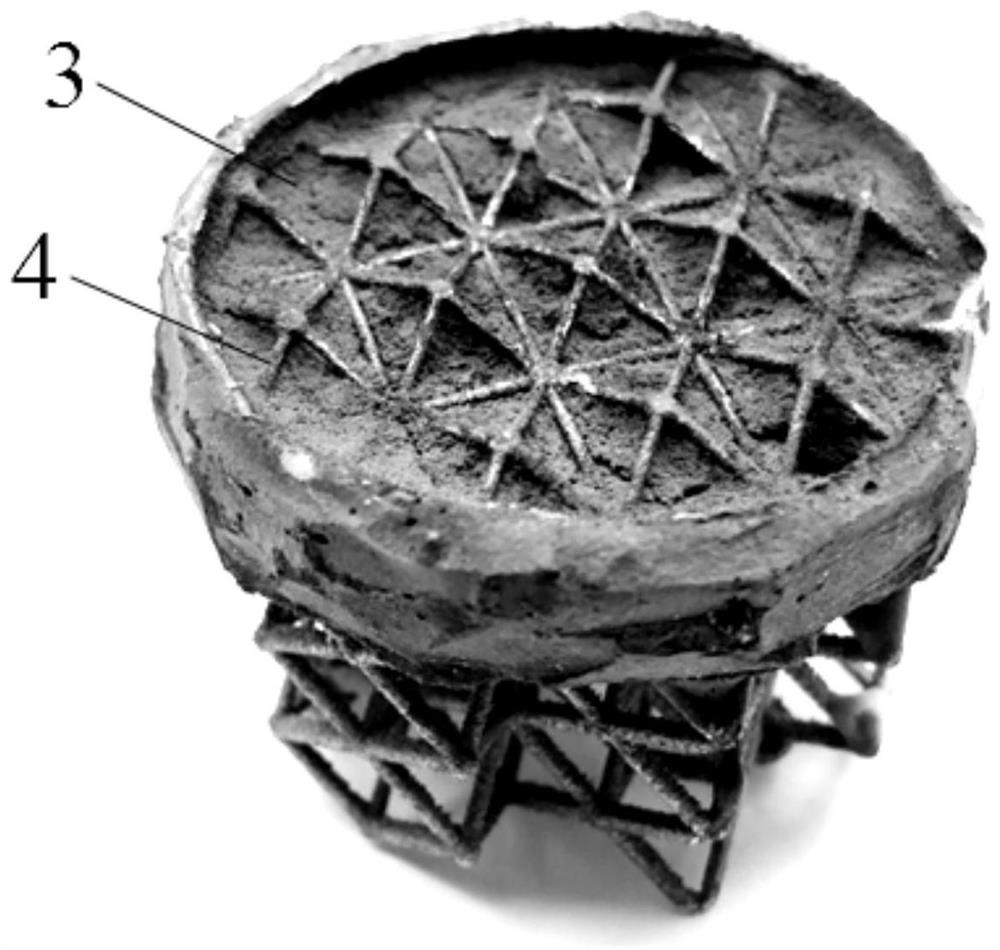

[0027] The metal lattice reinforced ablative material sandwich plate structure proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0028] see Figures 1 to 3 , a metal lattice reinforced ablative material sandwich panel structure, comprising an integrally formed metal lattice sandwich panel skeleton 8 and internal filling material; the integrally formed metal lattice sandwich panel skeleton 8 includes a first metal lattice core 4 and the connecting rod between the lattice core, the second metal lattice core 6 and the connecting rod between the lattice cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com