Preparation method of wear-resistant wood veneer decorative plate

A decorative board and wood veneer technology, applied in the field of material chemistry, can solve the problem that the decorative board cannot be engraved inside the texture, etc., to achieve the effect of increasing diversity, reducing breakage rate, and increasing clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

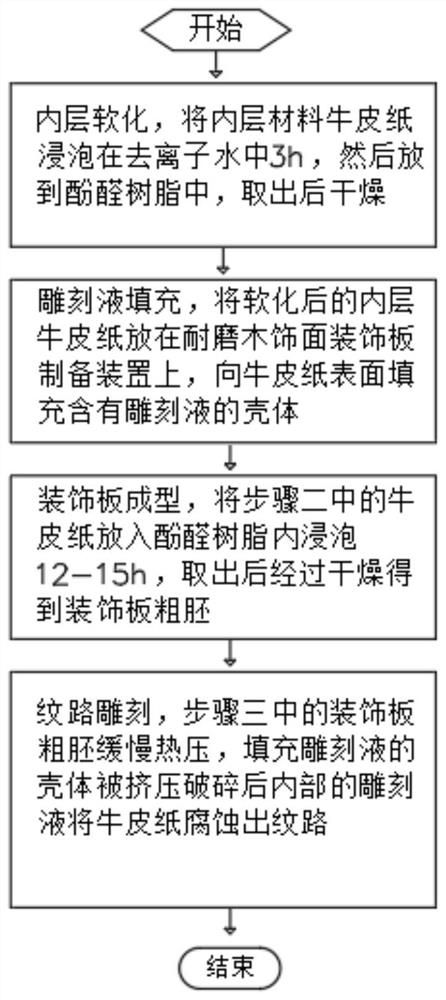

[0038] see figure 1 , the present invention provides a technical solution: a method for preparing a wear-resistant wood veneer decorative board, comprising the following steps:

[0039] Step 1: soften the inner layer, soak the inner material kraft paper in deionized water for 3 hours, then put it in phenolic resin, take it out and dry it;

[0040] Step 2, filling with engraving liquid, placing the softened inner kraft paper on the wear-resistant wood veneer decorative board preparation device, and filling the shell containing engraving liquid on the surface of the kraft paper;

[0041] Step 3, forming the decorative board, putting the kraft paper in step 2 into phenolic resin and soaking for 12-15 hours, taking it out and drying to obtain the rough embryo of the decorative board;

[0042] Step 4, texture engraving. In step 3, the rough embryo of the decorative board is slowly hot-pressed, and the shell filled with engraving fluid is squeezed and broken, and the engraving flui...

Embodiment 2

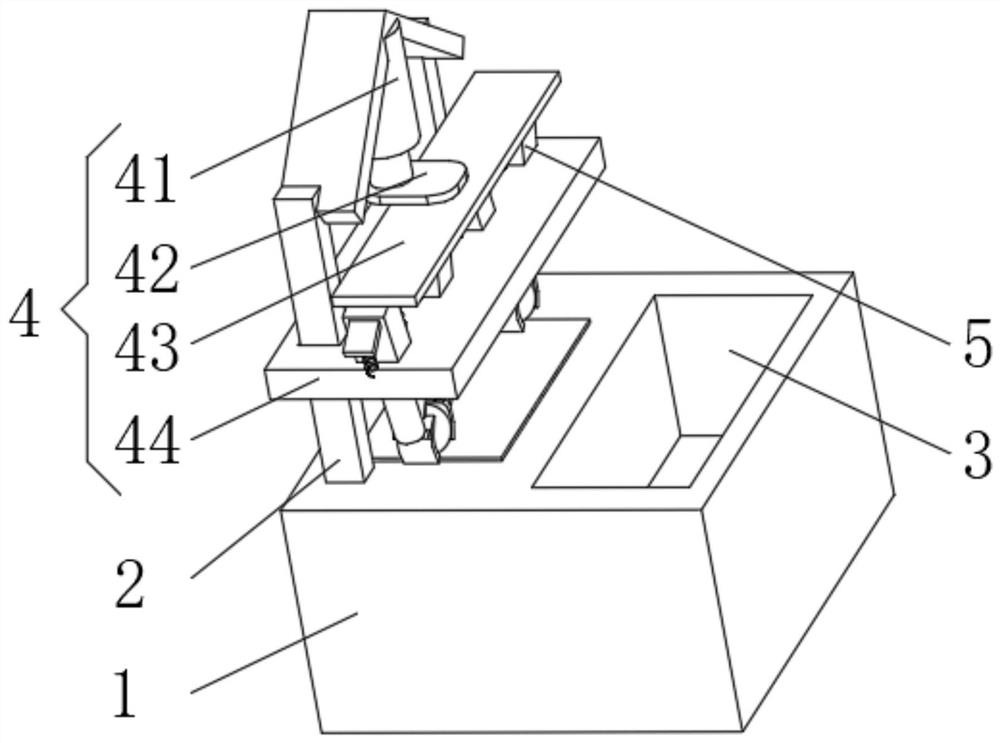

[0044] see Figure 2-6 , the present invention provides a technical solution: a preparation device for wear-resistant wood veneer decorative boards, including an operating table 1, a support frame 2 is installed on the top of the operating table 1, a soaking pool 3 is provided on the top of the operating table 1, and the operation Kraft paper is arranged on the top of platform 1 below the support frame 2, and the support frame 2 is provided with:

[0045] Lifting device 4, the lifting device 4 has a hydraulic cylinder 41, one end of the bottom of the hydraulic cylinder 41 is provided with a pressing plate 42, the bottom of the pressing plate 42 is slidably connected with a contact plate 43, and the outside of the support frame 2 is sleeved under the contact plate 43 There is a hot pressing plate 44, and the hot pressing plate 44 extends to the bottom of the contact plate 43;

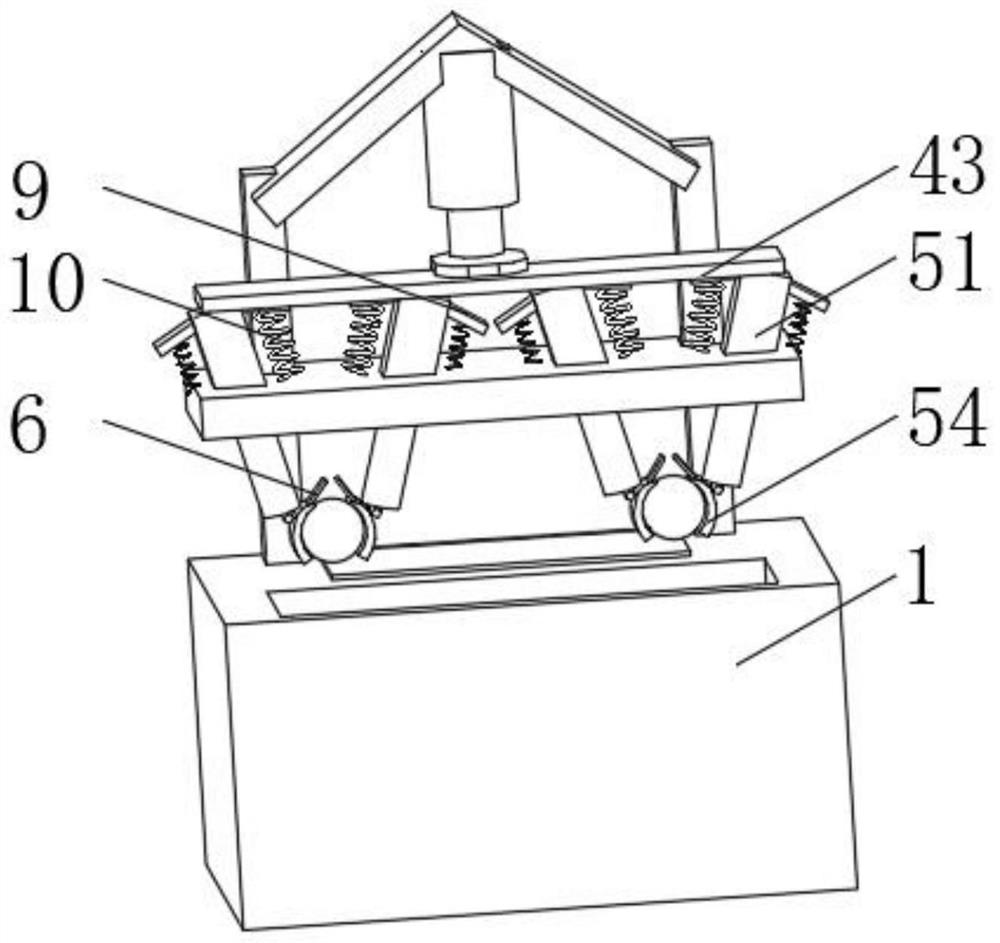

[0046] Filling device 5, the filling device 5 has an outer cylinder 51, the outer cylinder 51 runs t...

Embodiment 3

[0051] see Figure 2-6 , the present invention provides a technical solution: on the basis of the second embodiment, the support frame 2 is provided with an alarm device 6, the alarm device 6 has an inclined plate 61, and the inside of the inclined plate 61 is provided with an alarm groove 62, and the alarm groove 62 A power supply 63 and a butt joint 64 are installed inside the power supply 63 and a butt joint 64, and are electrically connected by a lead 65. The top of the inclined plate 61 is equipped with a warning light 66, which is electrically connected between the warning light 66 and the lead 65.

[0052] A U-shaped groove 11 is opened on one side of the inclined plate 61 , and a magnet block 12 is mounted inside the U-shaped groove 11 .

[0053] The side of the clamping plate 54 close to the fragile shell 7 is provided with a protective groove 13 , and the inside of the protective groove 13 is filled with foam blocks 14 .

[0054] One side of the inner wall of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com