Pantograph sinking platform coating structure

A cladding structure and pantograph technology, applied in the field of pantograph sunken platform cladding structure, can solve the problems of sunken platform size, form constraints, etc., to weaken the direct impact effect, reduce aerodynamic noise, and ease flow The effect of instability and oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

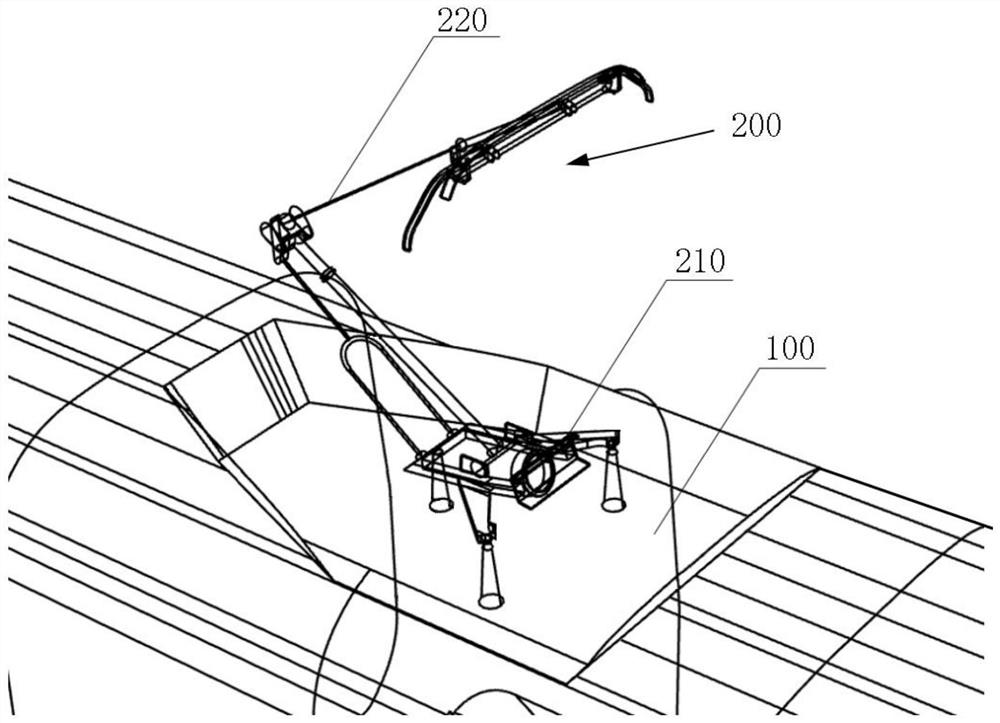

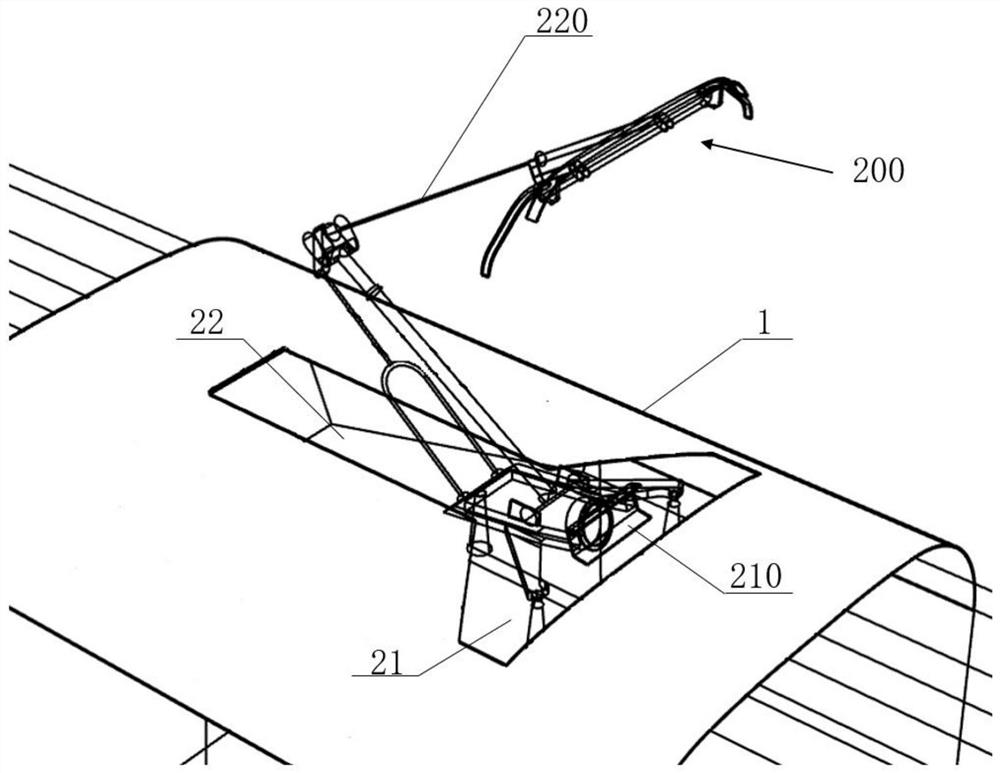

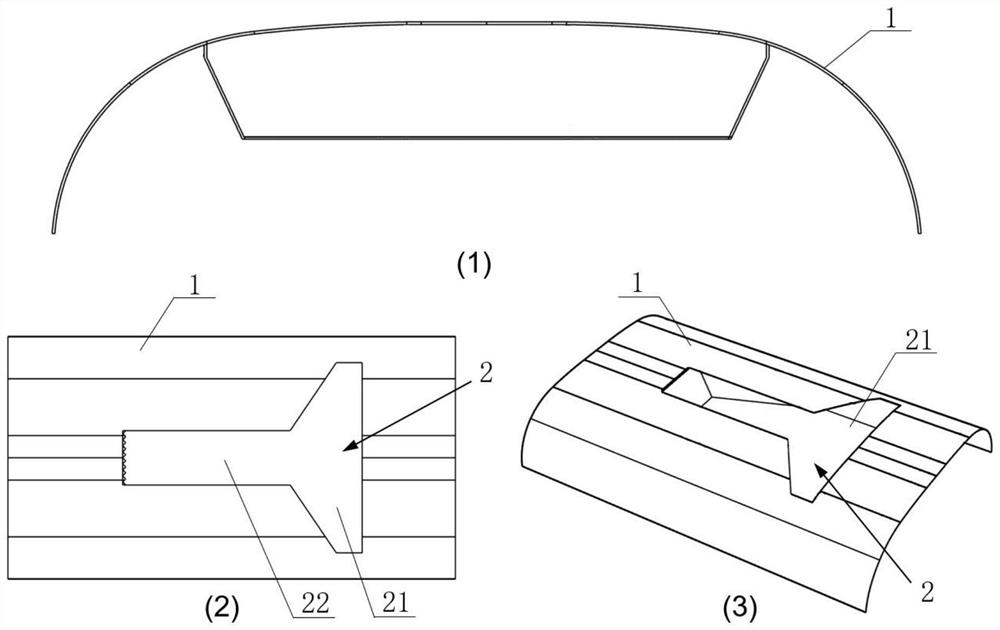

[0035] see figure 2 , image 3 with Figure 4 , a pantograph sinking platform cladding structure according to an embodiment of the present invention, the cladding structure mainly includes a top cladding plate 1, and the top cladding plate 1 covers the pantograph sinking platform on the top of the train 100, and the top surface cladding plate 1 has a streamlined transition with the roof of the train; the top surface cladding plate 1 partially covers the original pantograph sinking platform 100 on the top of the train, forming a pantograph 200 for accommodating The pantograph storage slot 2.

[0036] In the pantograph sinking platform cladding structure described above, the top cladding plate 1 is connected to the edge of the pantograph sinking platform 100 of the train, and the top cladding plate 1 is used to partially cover the original receiving plate on the top of the train. The pantograph is sunk into the platform 100 to form a pantograph storage slot 2, and the top cl...

Embodiment 2

[0047] see Figure 8 , a pantograph sinking platform cladding structure according to an embodiment of the present invention, the main structure of the pantograph sinking platform cladding structure is the same as that of Example 1, and the cladding structure is mainly different from that of Example 1 That is: the structure of the top surface cladding plate 1 is different from that of the first embodiment.

[0048] In Embodiment 1, the top surface cladding plate 1 remains flush with the car body on the top surface of the train; while in this embodiment, the top surface cladding plate 1 takes the form of a cladding plate convex, that is, the top surface cladding plate 1 The part close to the pantograph storage groove 2 protrudes upwards, and the protruding part has a streamlined transition with other parts of the top cladding plate 1. For its structure, see Figure 8 shown. The top surface cladding plate 1 is a convex cladding plate as a whole.

[0049] The cladding structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com