A kind of ultra-high performance concrete with low shrinkage and high elastic modulus and preparation method thereof

An ultra-high-performance and high-elasticity technology, applied in the field of concrete, can solve the problems of high cost and large shrinkage of ultra-high-performance concrete, and achieve the effect of reducing cement consumption, reducing section size and component quality, and improving elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

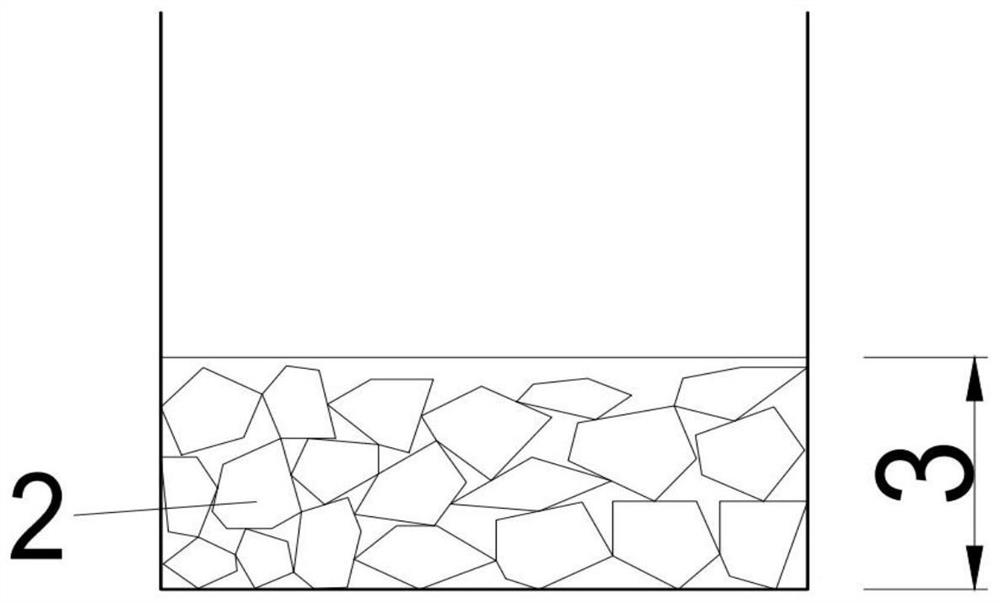

[0038] Example 1: A low-shrinkage, high-elastic-modulus ultra-high-performance concrete of this example consists of 36 parts by mass of cement, 0 part of silica fume, 0 part of fly ash, 15 parts of river sand, and high-standard gravel 200 parts of superplasticizer, 0.6 parts of high-efficiency water reducing agent, 2.7 parts of arcuate copper-plated steel fiber and 6.5 parts of water. The proportion is ≤3wt%, and the diameter of the arcuate copper-coated steel fiber is 0.2mm, and the length is 15mm.

Embodiment 2

[0039] Embodiment 2: A kind of ultra-high performance concrete with low shrinkage and high modulus of elasticity of the embodiment consists of 23.7 parts by mass of cement, 1.8 parts of silica fume, 10.8 parts of fly ash, 15 parts of river sand, and 200 parts of high-standard gravel 0.7 parts of high-efficiency superplasticizer, 2.7 parts of arc-shaped copper-plated steel fibers and 5.9 parts of water. The elastic modulus of the high-standard crushed stones is ≥60GPa, and the needle-shaped and flaky crushed stones in the high-standard crushed stones account for Ratio≤3wt%, the arcuate copper-coated steel fiber has a diameter of 0.2mm and a length of 15mm.

Embodiment 3

[0040] Embodiment 3: A kind of ultra-high performance concrete with low shrinkage and high modulus of elasticity of the embodiment consists of 23.5 parts of cement, 0 parts of silica fume, 12.6 parts of fly ash, 15 parts of river sand, and 200 parts of high-standard crushed stone in parts by mass. 1 part, 0.5 part of high-efficiency water reducer, 2.8 parts of bow-shaped copper-plated steel fiber and 6.1 parts of water. Ratio≤3wt%, the arcuate copper-coated steel fiber has a diameter of 0.2mm and a length of 15mm.

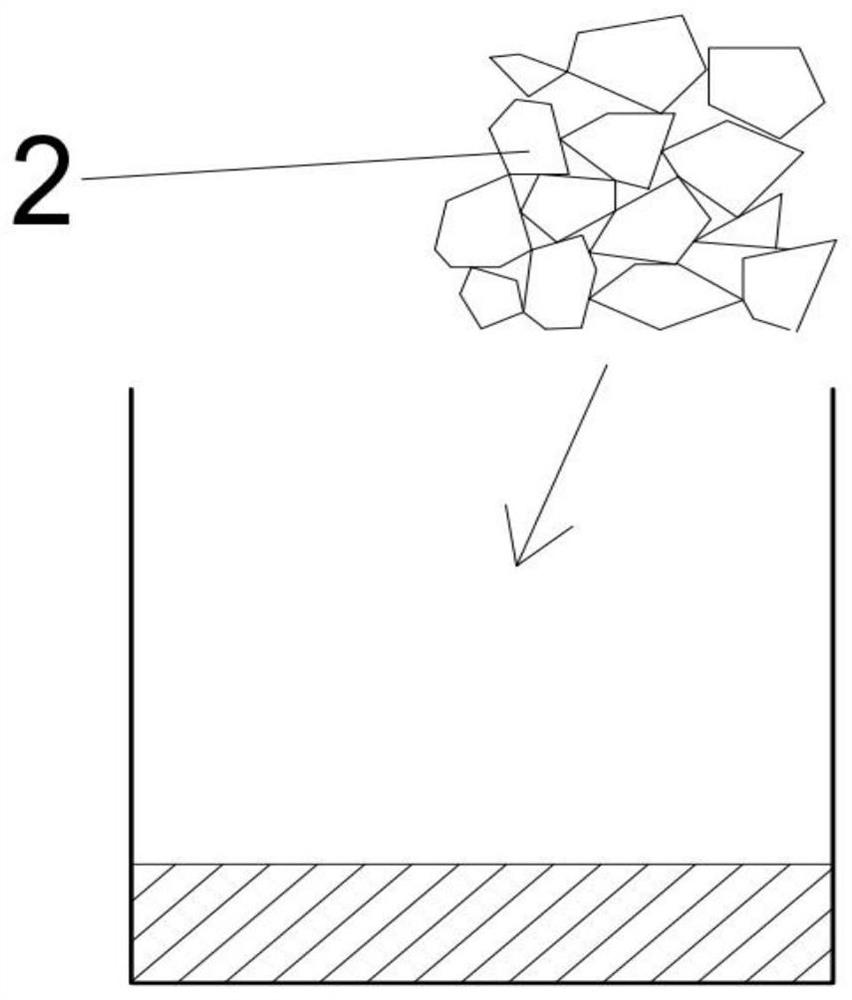

[0041] The preparation method of the ultra-high performance concrete with low shrinkage and high elastic modulus of preparation embodiment 1-3 is carried out as follows:

[0042] Step 1: Mix water and high-efficiency superplasticizer in advance to obtain an aqueous solution of superplasticizer;

[0043] Step 2: Pour cement and river sand into the mixer in turn and mix and stir for 5 minutes, add water reducer aqueous solution and continue stirring for 3 minutes, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com