Single-component airtight adhesive and preparation method thereof

An adhesive, one-component technology, used in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of high hardness of epoxy adhesives, inability to bend writing devices, and high modulus. problem, to achieve the effect of excellent mechanics, excellent stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

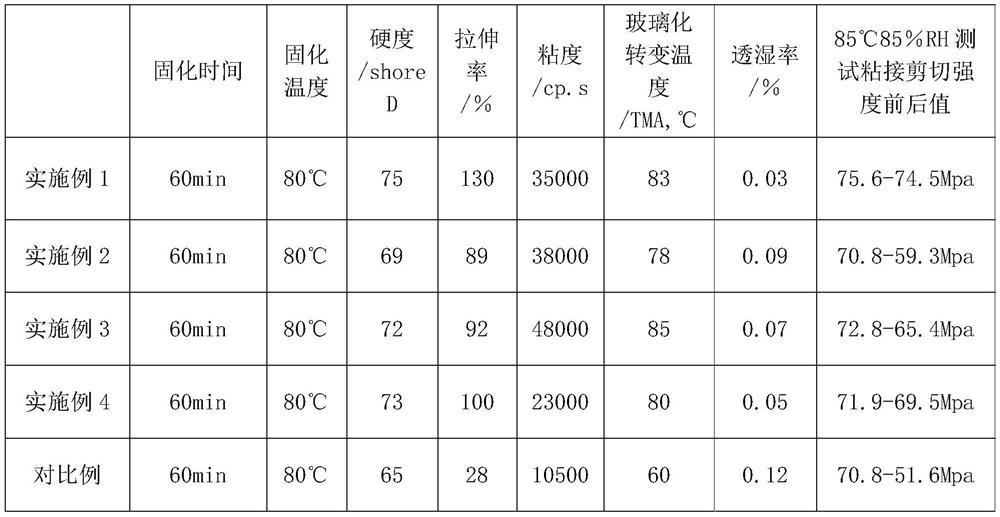

Examples

preparation example Construction

[0054] The second aspect of the present invention provides a method for preparing a one-component airtight adhesive. The preparation method for the one-component airtight adhesive includes the following preparation steps: premixing the raw materials of the airtight adhesive, aging, filtering, It can be obtained by dispersing and refining.

[0055] The one-component airtight adhesive in the invention can be used in the fields of electronics, aviation, aerospace, etc., and the airtight sealing of flexible display thin film devices, so as to improve the service life.

[0056] In addition, unless otherwise specified, the raw materials used in the present invention can be obtained commercially.

Embodiment 1

[0059] A kind of one-component airtight adhesive, the raw material of described airtight adhesive comprises, by weight, 40 parts of epoxy resins, 6.5 parts of multifunctional epoxy monomers, 10 parts of nitrile rubbers, 24.5 parts of curing agents, even 3 parts of joint agent, 20 parts of inorganic filler, 2 parts of fumed silica, 0.2 parts of stabilizer;

[0060] Described epoxy resin comprises organosilicon epoxy resin; The raw material of described organosilicon epoxy resin comprises novolac epoxy resin, organosilicon resin, and its weight ratio is 89:10; The preparation method of described organosilicon epoxy resin is : Mix novolac epoxy resin and silicone resin in a reaction vessel, then add catalyst, stir and react at 120°C for 2.5h to obtain silicone epoxy resin; the catalyst is dibutyltin dilaurate (CAS No.: 77- 58-7); The weight ratio of the catalyst to the silicone resin is 1:10; the epoxy equivalent of the novolak epoxy resin is 174g / eq; the novolak epoxy resin is J...

Embodiment 2

[0069] A one-component airtight adhesive, its specific implementation method is the same as that of Example 1, the difference is that there is no polyurethane modified epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com