Roof deformation joint waterproof structure and construction method

A waterproof structure and deformation seam technology, applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve the problems of easy falling of sealing paste, tearing of the waterproof layer of the coil, affecting the appearance and use requirements, etc., to achieve replacement The effect of low cost, shortened construction period and reduced process implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

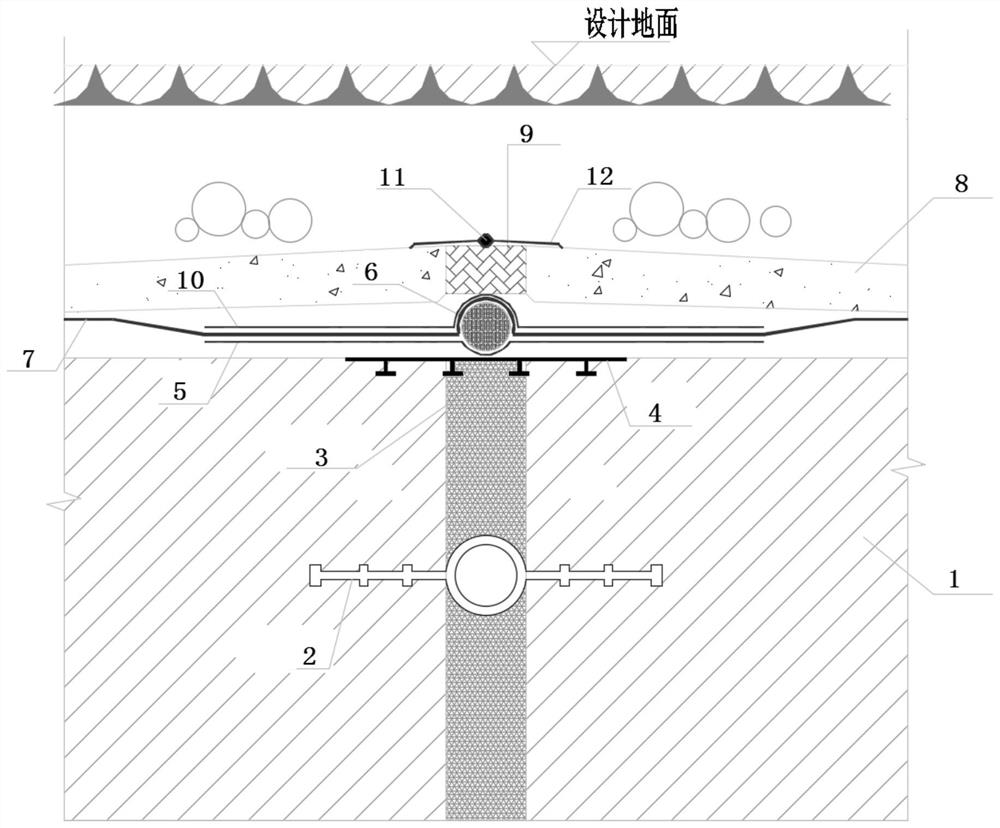

[0026] see figure 1 , a roof deformation joint waterproof structure provided by the embodiment of the present invention, including two roofs 1 and a roof deformation joint in the middle of the two roofs. The water belt 2, the top plate deformation joint is located above and below the buried rubber water stop belt 2, filled with polyethylene foam caulking board 3, and the upper port of the top plate deformation joint is covered with an externally attached water stop belt 4, which is externally attached The top surface of the waterstop 4 and the top plates 1 on both sides is covered with a coile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com