Extrusion deformation fastener and assembling method thereof

A technology of extrusion deformation and fasteners, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve problems such as failure to meet assembly requirements, failure of product assembly, slipping of wrench tools, etc., to achieve Simple structure, easy to process and manufacture, avoid slipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

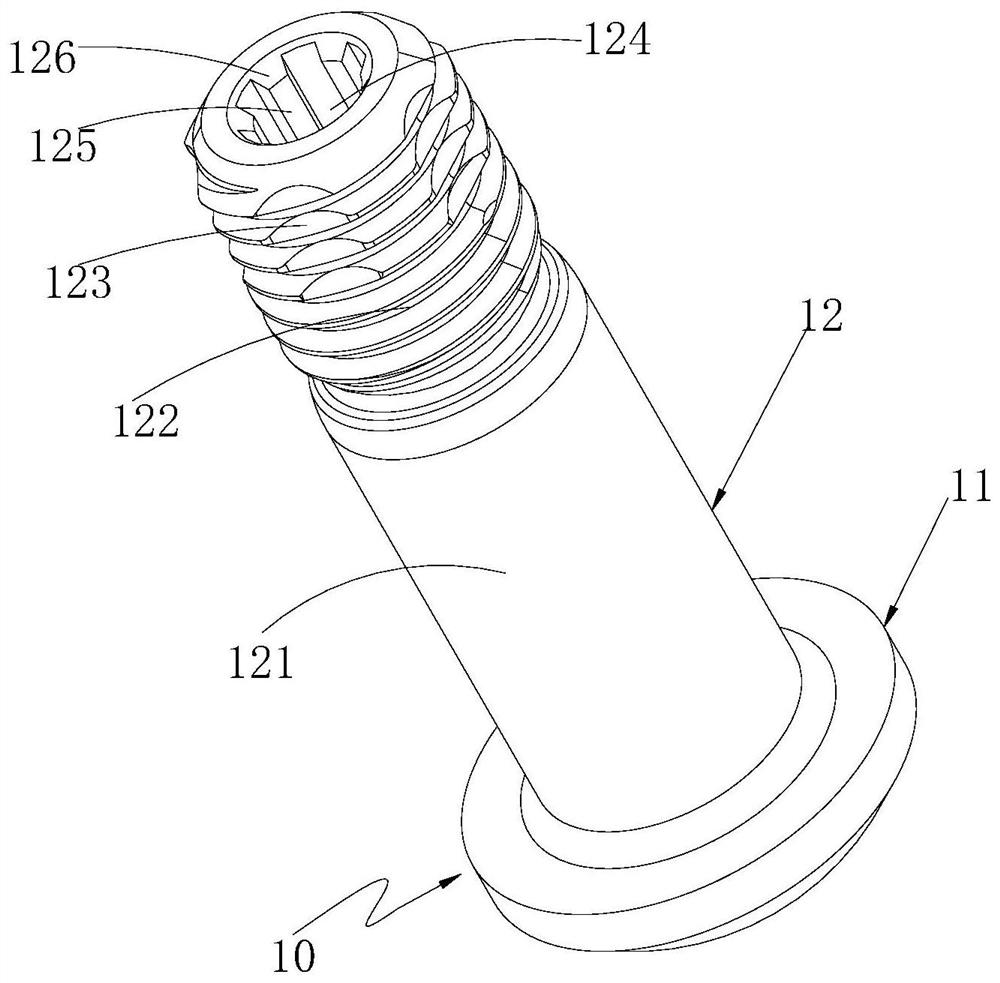

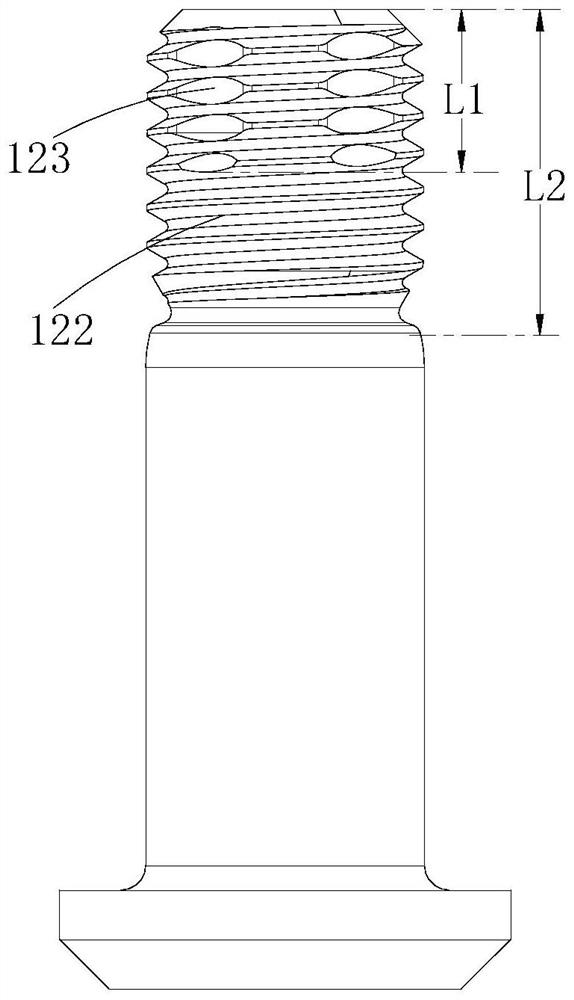

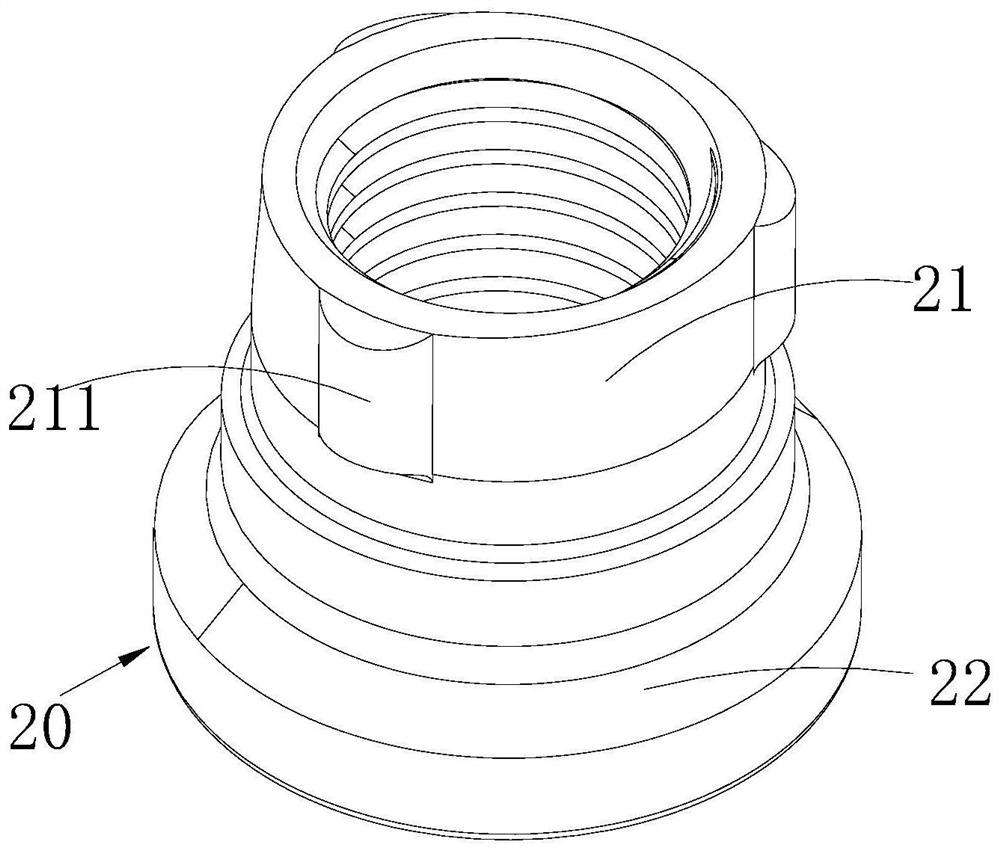

[0028] refer to figure 1 , figure 2 , Figure 6 and Figure 7 , an extrusion deformation fastener, the fastener 10 includes a head 11 and a rod body 12, the rod body 12 has a smooth section 121 and a threaded section 122, the head 11, the smooth section 121 and the threaded section The section 122 is set as an integral structure, and the head 11, the smooth section 121 and the threaded section 122 adopt known structures and designs; the outer wall of the threaded section 122 is provided with at least one recess 123, and the high lock nut 20 is deformed by extrusion The rear part squeezes into the recesses 123 to form self-locking; preferably, five recesses 123 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com